JIC Ti - 80mm OK for N/A?

#1

Debating getting this exhaust for my 03. Some of the vendors have the 80mm version in stock. The 60mm version would be special order and therefore more expensive.

So obviously the 80mm would work OK on a N/A engine, but would the 60mm be significantly better for that application?

TIA

So obviously the 80mm would work OK on a N/A engine, but would the 60mm be significantly better for that application?

TIA

#2

MOTORDYNE-MY350Z SPONSOR

iTrader: (53)

80mm is just fine.

For any system "Y-back" you can't have too large of tubing. There is no compromise of TQ by going larger and larger. With one exception, the only thing a Y-back can do is "potentially" reduce HP if there is excessive back pressure. The one exception would be a diffuser or megaphone which can reduce pressure drop below that of an open pipe.

TQ is determined by the diameter of tubing upstream of the end of the Y-pipe. So in other words, TQ is determined by the Y-pipe primary diameters and a few inches past the merge collector.

You could do a pre/post dyno where you unbolt the JIC from the Y-pipe and it will make no difference in TQ and very little difference in HP.

The only thing a 60MM Y-back can do is reduce the HP a little more with the added possibility of reduced TQ.

...At least this is what I found with a lot of exhaust testing on the dyno.

For any system "Y-back" you can't have too large of tubing. There is no compromise of TQ by going larger and larger. With one exception, the only thing a Y-back can do is "potentially" reduce HP if there is excessive back pressure. The one exception would be a diffuser or megaphone which can reduce pressure drop below that of an open pipe.

TQ is determined by the diameter of tubing upstream of the end of the Y-pipe. So in other words, TQ is determined by the Y-pipe primary diameters and a few inches past the merge collector.

You could do a pre/post dyno where you unbolt the JIC from the Y-pipe and it will make no difference in TQ and very little difference in HP.

The only thing a 60MM Y-back can do is reduce the HP a little more with the added possibility of reduced TQ.

...At least this is what I found with a lot of exhaust testing on the dyno.

#3

Registered User

iTrader: (19)

Join Date: Apr 2007

Location: Houston,TX

Posts: 1,395

Likes: 0

Received 0 Likes

on

0 Posts

Debating getting this exhaust for my 03. Some of the vendors have the 80mm version in stock. The 60mm version would be special order and therefore more expensive.

So obviously the 80mm would work OK on a N/A engine, but would the 60mm be significantly better for that application?

TIA

So obviously the 80mm would work OK on a N/A engine, but would the 60mm be significantly better for that application?

TIA

but A/F was completely off (for a track use)

the best thing you can do is look for a jic TI on the used marketplace (p.s. that exhaust is freaking loud) but the best gain you'll have is shave more than 40lbs from your car (besides the WHP gain)

Trending Topics

#8

Super Moderator

MY350Z.COM

MY350Z.COM

iTrader: (8)

#12

Registered User

iTrader: (3)

Join Date: Apr 2007

Location: Southeast PA

Posts: 91

Likes: 0

Received 0 Likes

on

0 Posts

Tony, thanks for the info, that's why this forum rocks. But, my understanding is that for an N/A application, a 70-80mm pipe could reduce back pressure and therefore reduce TQ. Is that incorrect?

Last edited by Stunnd; 06-15-2009 at 04:05 AM. Reason: wanted to

#15

MOTORDYNE-MY350Z SPONSOR

iTrader: (53)

Back pressure (at least on our engine) is NEVER a good thing for NA applications.

It is a widely spread myth that some back pressure is good, but it is 100% FALSE.

There clearly are situations where smaller diameter pipes can outperform larger diameter pipes but this is not because of back pressure. This is because of scavenging. And when tuned properly, scavenging actually reduces back pressure as seen by the engine.

But be careful in the assumption that smaller automatically equals better performance. It is highly dependent on where the smaller diameter pipes are being used.

Small pipes near the engine can be good for scavenging and power, but as the pipes move farther and farther away from the engine the effect of scavenging rapidly diminishes. If scavenging cannot be taken advantage of, then small/restrictive pipes must be completely avoided.

Back pressure can only reduce power. Do not confuse this with scavenging.

Scavenging actually reduces back pressure on a tuned cyclical basis.

With each pulse released during the exhaust stroke of the engine, the pulse travels like a shotgun blast down the exhaust pipes. The high intensity blast creates a shockwave with a large positive pressure at the wave front. This wave front is traveling so fast that even when the piston reaches TDC and all the gas is expelled by the piston, the fast moving slug of exhaust gas doesn't stop and it rarefies the gas and creates a vacuum behind the shockwave.

It is the vacuum behind the shockwave that sucks out any remaining exhaust gas from the cylinder. This vacuum also pulls more fuel/air mixture through the intake valves during the intake/exhaust valve overlap period. And this is how more power is made. This is the scavenging effect. It vacuums exhaust gas out of your engine!

Adding back pressure can only kill off this vacuum that you want.

NOW HERE IS HOW THE MYTH STARTED.

IT WAS A MISINTERPRETATION OF TEST RESULTS.

Sombody a long time ago probably did the same series of dyno tests I did on varying pipe diameters. Like I did, they probably found that smaller diameter pipes can yeild higher HP and TQ. They probably mistook this for back pressure and put it out in the public. Smaller diameter pipes can provide higher performance when used properly. But small diameter pipes are only desirable when they are very close to the engine.

For example:

I did a series of dyno tests on various diameter test pipes ranging from 2.5", 2.25" and 2.0".

Before conducting the tests, my initial guess was that the larger diameter pipes would produce the highest HP with lowest TQ. And the smaller diameter pipes would produce the lowest HP and the highest TQ.

Well... I was 1/2 right...

As expected, the dyno testing showed the 2.5" diameter test pipes made the lowest TQ. And as expected, the dyno testing showed the 2.0" diameter test pipes made the highest TQ.

But here's the kicker. The 2.0" test pipes made 2 more HP than the 2.5" test pipes! ...It left me thinking "COOL. Smaller diameter test pipes make more TQ and more HP. That's a wining combination!"

Smaller diameter test pipes make more TQ and more HP. That's a wining combination!"

So sombody a long time ago probably misinterpreted the smaller diameter as adding performance by being more restrictive. But this is not the case. It is because of increased scavenging. Smaller diameter pipes near the engine increase the velocity of the shockwave and thereby increasing the effect of scavenging. It was a misinterpretation of the results.

So I continued down this line of testing at the Y-pipe primaries. Using the 2.0" test pipes, I then tested various Y-pipe primary diameters. 2.0", 2.25" and 2.5".

The expectation was to see similar results... but not quite this time. At least not at the Y-pipe.

The 2.0" Y-pipe primaries did indeed provide the highest TQ, but it brought a good portion of the HP down. 2.25" primaries were better but could still be improved upon. The 2.5" Y-pipe primaries provided the best peak power and the best average power.

So dyno testing proved the best test pipe diameter is 2.0" diameter and the best Y-pipe primary diameter is 2.5".

I then continued further down this line of testing on the mid-pipe and made some more interesting observations. Testing mid-pipe diameters at 2.5", 3.0" and then a fully open Y-pipe.

What I did find was that there was no scavenging effect possible after the Y-pipe. There was nothing to gain from the smaller diameter what so ever. In fact, the only thing that had any effect was simple back pressure.

Using a open Y-pipe as the baseline I found that connecting a 3" single exhaust had no effect on TQ and with only a small 1.5 HP decrease.

The 2.5" midpipe slightly reduced TQ and was ~2.5HP down from than the 3" midpipe.

This series of tests established:

1) There was no scavenging possible after the Y-pipe.

2) A smaller diameter midpipe can only decrease HP&TQ

3) There will be rapidly diminishing returns beyond a 3" midpipe

4) With power to weight ratios taken into consideration a 3" midpipe can be considered optimum. 3" also allows more headroom for medium boost FI applications.

Going from 3" to a 3.5" midpipe may at best provide a 0.5HP increase. So from a weight point of view, going larger than 3.0" would be counter productive for NA applications.

I then conducted another series of tests at the end of the Y-pipe.

1) Attaching a 3" diameter butterfly valve with variable position restriction plate.

2) Attaching a 6" diameter parabolic diffuser to reduces pressure drop below that of a 3" open pipe.

The purpose of the butterfly valve restriction plate was to directly test the effect of raw back pressure on performance. And the results were very clear.

BACK PRESSURE RAPIDLY REDUCES PERFORMANCE.

I dyno tested the valve at various levels of flow restriction. From wide open to almost fully closed as back pressure was increased, performance rapidly decreased.

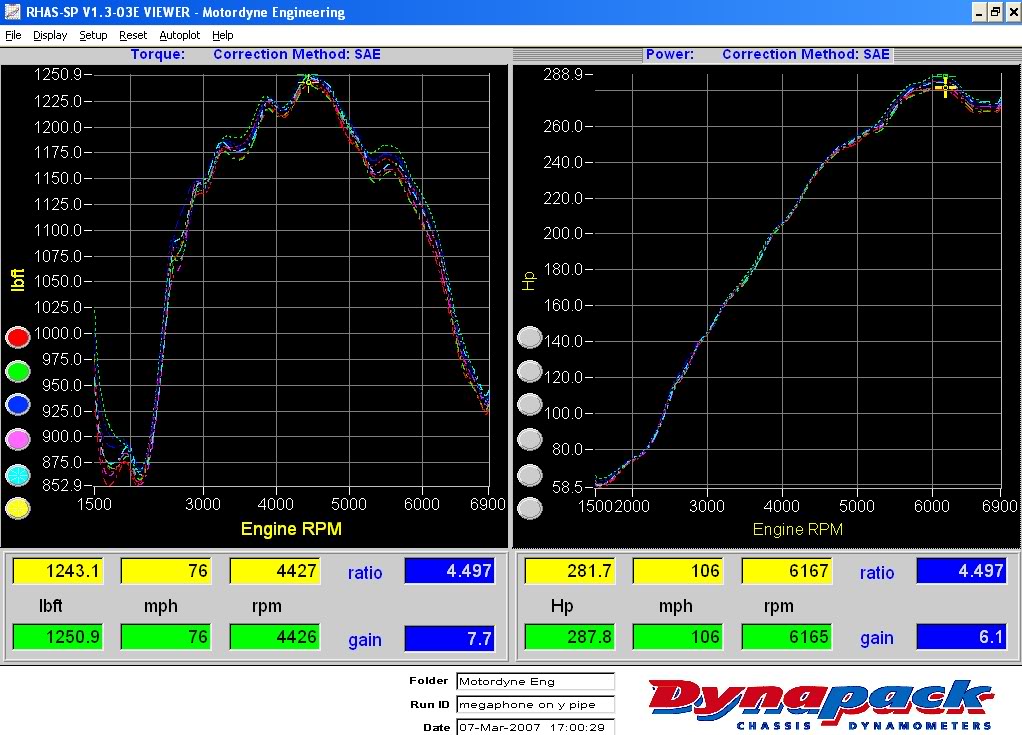

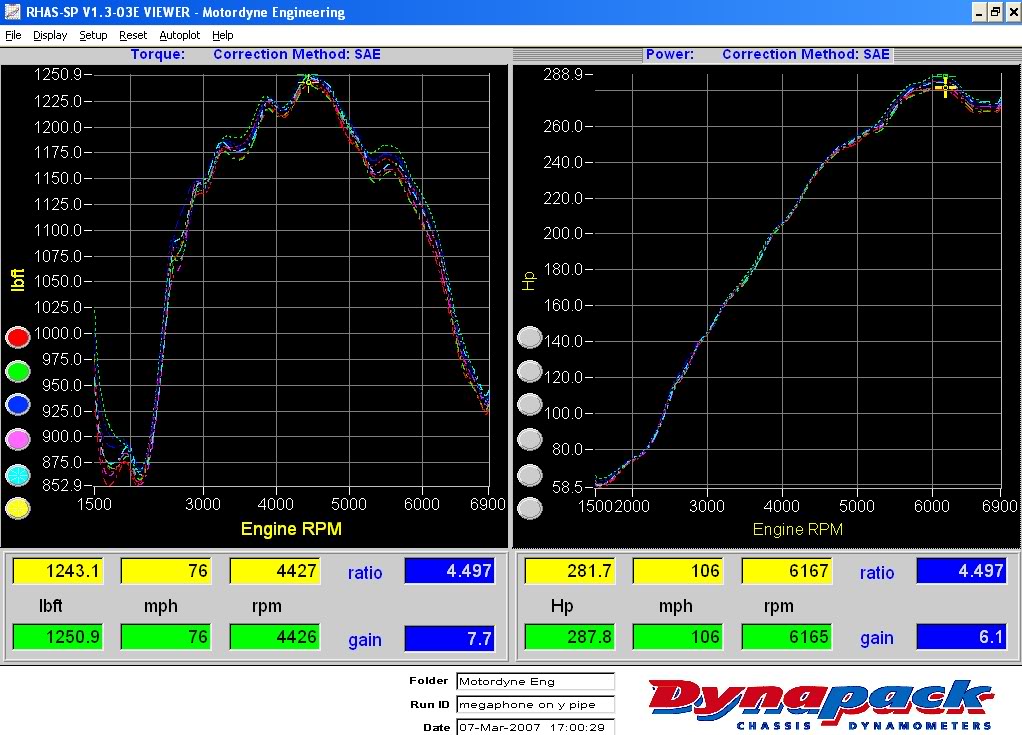

This set of dyno plots is proof positive that back pressure is the enemy of power and torque.

Let the myth of back pressure be permanently dispelled from the vocabulary of this forum!

After that series of tests I started another set of tests that decreased exhaust pressure beyond that of a simple open ended 3" pipe.

A 6" diameter parabolic diffuser was clamped onto the end of the Y-pipe. This was used to decrease flow resistance below that of a open pipe.

Dyno tests of the diffuser showed an instant 4-6HP increase over that of a open Y-pipe!

This picture below is a picture of a 5" linear diffuser. It doesn't perform quite as good as the 6" parabolic diffuser but the 6" diffuser is completely impractical for fitment and production reasons.

6" is too big for fitment under the Z and the parabolic shape also gives it a curvature that makes the production process MUCH more difficult.

This is the diffuser used on the MD ShockWave single exhaust system. It can also be attached directly to the Y-pipe for drag race applications.

So while there are rapidly diminishing returns with going to larger and larger diameter tubing after the Y-pipe, significant gains can still be made by use of diffusers.

The back to back dyno testing shown below was a simple open Y-pipe as the baseline and then with the diffuser attached.

It is a widely spread myth that some back pressure is good, but it is 100% FALSE.

There clearly are situations where smaller diameter pipes can outperform larger diameter pipes but this is not because of back pressure. This is because of scavenging. And when tuned properly, scavenging actually reduces back pressure as seen by the engine.

But be careful in the assumption that smaller automatically equals better performance. It is highly dependent on where the smaller diameter pipes are being used.

Small pipes near the engine can be good for scavenging and power, but as the pipes move farther and farther away from the engine the effect of scavenging rapidly diminishes. If scavenging cannot be taken advantage of, then small/restrictive pipes must be completely avoided.

Back pressure can only reduce power. Do not confuse this with scavenging.

Scavenging actually reduces back pressure on a tuned cyclical basis.

With each pulse released during the exhaust stroke of the engine, the pulse travels like a shotgun blast down the exhaust pipes. The high intensity blast creates a shockwave with a large positive pressure at the wave front. This wave front is traveling so fast that even when the piston reaches TDC and all the gas is expelled by the piston, the fast moving slug of exhaust gas doesn't stop and it rarefies the gas and creates a vacuum behind the shockwave.

It is the vacuum behind the shockwave that sucks out any remaining exhaust gas from the cylinder. This vacuum also pulls more fuel/air mixture through the intake valves during the intake/exhaust valve overlap period. And this is how more power is made. This is the scavenging effect. It vacuums exhaust gas out of your engine!

Adding back pressure can only kill off this vacuum that you want.

NOW HERE IS HOW THE MYTH STARTED.

IT WAS A MISINTERPRETATION OF TEST RESULTS.

Sombody a long time ago probably did the same series of dyno tests I did on varying pipe diameters. Like I did, they probably found that smaller diameter pipes can yeild higher HP and TQ. They probably mistook this for back pressure and put it out in the public. Smaller diameter pipes can provide higher performance when used properly. But small diameter pipes are only desirable when they are very close to the engine.

For example:

I did a series of dyno tests on various diameter test pipes ranging from 2.5", 2.25" and 2.0".

Before conducting the tests, my initial guess was that the larger diameter pipes would produce the highest HP with lowest TQ. And the smaller diameter pipes would produce the lowest HP and the highest TQ.

Well... I was 1/2 right...

As expected, the dyno testing showed the 2.5" diameter test pipes made the lowest TQ. And as expected, the dyno testing showed the 2.0" diameter test pipes made the highest TQ.

But here's the kicker. The 2.0" test pipes made 2 more HP than the 2.5" test pipes! ...It left me thinking "COOL.

Smaller diameter test pipes make more TQ and more HP. That's a wining combination!"

Smaller diameter test pipes make more TQ and more HP. That's a wining combination!"So sombody a long time ago probably misinterpreted the smaller diameter as adding performance by being more restrictive. But this is not the case. It is because of increased scavenging. Smaller diameter pipes near the engine increase the velocity of the shockwave and thereby increasing the effect of scavenging. It was a misinterpretation of the results.

So I continued down this line of testing at the Y-pipe primaries. Using the 2.0" test pipes, I then tested various Y-pipe primary diameters. 2.0", 2.25" and 2.5".

The expectation was to see similar results... but not quite this time. At least not at the Y-pipe.

The 2.0" Y-pipe primaries did indeed provide the highest TQ, but it brought a good portion of the HP down. 2.25" primaries were better but could still be improved upon. The 2.5" Y-pipe primaries provided the best peak power and the best average power.

So dyno testing proved the best test pipe diameter is 2.0" diameter and the best Y-pipe primary diameter is 2.5".

I then continued further down this line of testing on the mid-pipe and made some more interesting observations. Testing mid-pipe diameters at 2.5", 3.0" and then a fully open Y-pipe.

What I did find was that there was no scavenging effect possible after the Y-pipe. There was nothing to gain from the smaller diameter what so ever. In fact, the only thing that had any effect was simple back pressure.

Using a open Y-pipe as the baseline I found that connecting a 3" single exhaust had no effect on TQ and with only a small 1.5 HP decrease.

The 2.5" midpipe slightly reduced TQ and was ~2.5HP down from than the 3" midpipe.

This series of tests established:

1) There was no scavenging possible after the Y-pipe.

2) A smaller diameter midpipe can only decrease HP&TQ

3) There will be rapidly diminishing returns beyond a 3" midpipe

4) With power to weight ratios taken into consideration a 3" midpipe can be considered optimum. 3" also allows more headroom for medium boost FI applications.

Going from 3" to a 3.5" midpipe may at best provide a 0.5HP increase. So from a weight point of view, going larger than 3.0" would be counter productive for NA applications.

I then conducted another series of tests at the end of the Y-pipe.

1) Attaching a 3" diameter butterfly valve with variable position restriction plate.

2) Attaching a 6" diameter parabolic diffuser to reduces pressure drop below that of a 3" open pipe.

The purpose of the butterfly valve restriction plate was to directly test the effect of raw back pressure on performance. And the results were very clear.

BACK PRESSURE RAPIDLY REDUCES PERFORMANCE.

I dyno tested the valve at various levels of flow restriction. From wide open to almost fully closed as back pressure was increased, performance rapidly decreased.

This set of dyno plots is proof positive that back pressure is the enemy of power and torque.

Let the myth of back pressure be permanently dispelled from the vocabulary of this forum!

After that series of tests I started another set of tests that decreased exhaust pressure beyond that of a simple open ended 3" pipe.

A 6" diameter parabolic diffuser was clamped onto the end of the Y-pipe. This was used to decrease flow resistance below that of a open pipe.

Dyno tests of the diffuser showed an instant 4-6HP increase over that of a open Y-pipe!

This picture below is a picture of a 5" linear diffuser. It doesn't perform quite as good as the 6" parabolic diffuser but the 6" diffuser is completely impractical for fitment and production reasons.

6" is too big for fitment under the Z and the parabolic shape also gives it a curvature that makes the production process MUCH more difficult.

This is the diffuser used on the MD ShockWave single exhaust system. It can also be attached directly to the Y-pipe for drag race applications.

So while there are rapidly diminishing returns with going to larger and larger diameter tubing after the Y-pipe, significant gains can still be made by use of diffusers.

The back to back dyno testing shown below was a simple open Y-pipe as the baseline and then with the diffuser attached.

Last edited by Hydrazine; 06-12-2009 at 05:25 PM.

The following 4 users liked this post by Hydrazine:

#16

MOTORDYNE-MY350Z SPONSOR

iTrader: (53)

To get an idea of how a diffuser works you need to consider all the kinetic energy being pumped out of the exhaust tail pipe.

For a normal exhaust system that uses 3" tubing conected to a muffler with a normal 3" outlet with a rapid expansion to a 4" or 5" tip, all the exhaust flow energy is wasted by shooting out all that exhaust gas at high velocity into the atmosphere.

If you have ever stood ~20 feet behind a car on the dyno you will see and feel the effects of all that energy being wasted. Standing behind a car on the dyno is like getting blasted by wind on a hot smoggy day.

It takes energy to move all that hot wind with such force. And all that wind is being blasted out of a 3" tube! So what is comming out of the tail pipe is quite intense. And its all just wasted energy.

But if you were to connect a 5" diffuser to a 3" tube the exhaust gas velocity will be slowed down and reduced by a fator of almost 3X.

And pressure drop is determined by rhoV^2/2g. In this case, rho and 2g remain constant and V^2 is the important variable.

Not only a diffuser brings the velocity down by a factor of nearly 3X. The total pressure recovery is determined by the square of the velocity. So the diffuser is recovering kinetic energy by converting Dynamic pressure into Static pressure.

So not only this means your engine doesn't have to waste energy by pumping out the exhaust gas so forcefully, it also makes it easier for a new fuel/air charge to get into the engine by means of scavenging.

Diffusers are commonly used in jet engines and rocket engines. They convert fluid movement into pressure. Or Dynamic pressure into Static pressure and vice/versa.

In the case of a I.C. engine we only want to efficiently convert dynamic pressure into static pressure. The way to do that is with a diffuser. For a diffuser to be efficient, it must be designed with the proper expansion ratio and diffusion angle. Like the cone shown above.

If you were to take a 5" exhaust tip and just bolt it onto a 3" pipe, it won't work. A regular exhaust tip has what is called a sudden expansion. It is unable to efficiently convert the kinetic energy into static pressure. It just dumps it into the atmosphere and wastes the fluid energy. But the diffuser organizes the flow in an orderly manner and gradually slows it down (efficiently) and all that kinetic energy is conserved.

The engine is still pumping out a lot of exhaust gas but a diffuser makes it a lot easier to do.

For a normal exhaust system that uses 3" tubing conected to a muffler with a normal 3" outlet with a rapid expansion to a 4" or 5" tip, all the exhaust flow energy is wasted by shooting out all that exhaust gas at high velocity into the atmosphere.

If you have ever stood ~20 feet behind a car on the dyno you will see and feel the effects of all that energy being wasted. Standing behind a car on the dyno is like getting blasted by wind on a hot smoggy day.

It takes energy to move all that hot wind with such force. And all that wind is being blasted out of a 3" tube! So what is comming out of the tail pipe is quite intense. And its all just wasted energy.

But if you were to connect a 5" diffuser to a 3" tube the exhaust gas velocity will be slowed down and reduced by a fator of almost 3X.

And pressure drop is determined by rhoV^2/2g. In this case, rho and 2g remain constant and V^2 is the important variable.

Not only a diffuser brings the velocity down by a factor of nearly 3X. The total pressure recovery is determined by the square of the velocity. So the diffuser is recovering kinetic energy by converting Dynamic pressure into Static pressure.

So not only this means your engine doesn't have to waste energy by pumping out the exhaust gas so forcefully, it also makes it easier for a new fuel/air charge to get into the engine by means of scavenging.

Diffusers are commonly used in jet engines and rocket engines. They convert fluid movement into pressure. Or Dynamic pressure into Static pressure and vice/versa.

In the case of a I.C. engine we only want to efficiently convert dynamic pressure into static pressure. The way to do that is with a diffuser. For a diffuser to be efficient, it must be designed with the proper expansion ratio and diffusion angle. Like the cone shown above.

If you were to take a 5" exhaust tip and just bolt it onto a 3" pipe, it won't work. A regular exhaust tip has what is called a sudden expansion. It is unable to efficiently convert the kinetic energy into static pressure. It just dumps it into the atmosphere and wastes the fluid energy. But the diffuser organizes the flow in an orderly manner and gradually slows it down (efficiently) and all that kinetic energy is conserved.

The engine is still pumping out a lot of exhaust gas but a diffuser makes it a lot easier to do.

The following 3 users liked this post by Hydrazine:

#17

Super Moderator

MY350Z.COM

MY350Z.COM

iTrader: (8)

^^^ what other company comes on here and explains their research/development, and has the dyno proof to back their products. Just another GOOD reason to buy from motordyne, his one on one customer service is better than most too.

!!

!!