i broke the rear shock bolts! what to do??

#43

i remember vaguely that there was a post about how someone drill thru the rear strut so that they could fit the dampener extension for their coilovers. i think its for bc coilover since thats the only one in mind that offers extensions.

i spent that last hour searching for the post with no luck. im trying to find it so i can get see where they drill at

i spent that last hour searching for the post with no luck. im trying to find it so i can get see where they drill at

#45

hatersgonnahate

iTrader: (162)

I am now at 84k miles and no problems yet. Well over 25k miles with this.

Keep in mind that the JB weld was just there to hold the bolt in place and not require a socket to tighten.

Keep in mind that the JB weld was just there to hold the bolt in place and not require a socket to tighten.

#46

so what did you do exactly.

"I drill out the studs with progressively large bits.

Once i had a nice hole, i used that weld putty that is good for some crazy strengths. I used a new HARDENED bolt/nut of similar diameter and put it all around the bolt head and smeared into the body. Let it cure for 30 minutes + and the reinstalled my strut."

so you drill a hole. i got that part. how did you stick a bolt along with the head in there without additional drilling to the strut area?

what is a HARDENED bolt? a grade 8 type bolt?

interesting and simple idea. i would love to know exactly how its done

"I drill out the studs with progressively large bits.

Once i had a nice hole, i used that weld putty that is good for some crazy strengths. I used a new HARDENED bolt/nut of similar diameter and put it all around the bolt head and smeared into the body. Let it cure for 30 minutes + and the reinstalled my strut."

so you drill a hole. i got that part. how did you stick a bolt along with the head in there without additional drilling to the strut area?

what is a HARDENED bolt? a grade 8 type bolt?

interesting and simple idea. i would love to know exactly how its done

#49

if its around 3 inches, then i think i will be comfortable with just cutting out one or 2 inch circle to grind out the old stud and weld in a bolt with a washer welded to it. i was afraid of this at first because i really didnt want to strip down the interior. but by the look of that picture i posted, it look like its only one or two piece that i need to remove.

oh btw winch, i spent 15 minute trying to get the rivet nut to work and it is hard as heck (tested on a spare sheet of metal). and i need to drill a hole a little bit larger than half an inch for it. so imma scratch that idea for now.

ill keep this post updated as to what i do. cause it seem like im not the only with this problem

oh btw winch, i spent 15 minute trying to get the rivet nut to work and it is hard as heck (tested on a spare sheet of metal). and i need to drill a hole a little bit larger than half an inch for it. so imma scratch that idea for now.

ill keep this post updated as to what i do. cause it seem like im not the only with this problem

#50

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

Sorry man, i have been meaning to try and take a look at this on my car, but Ive been too busy when i get home lately.

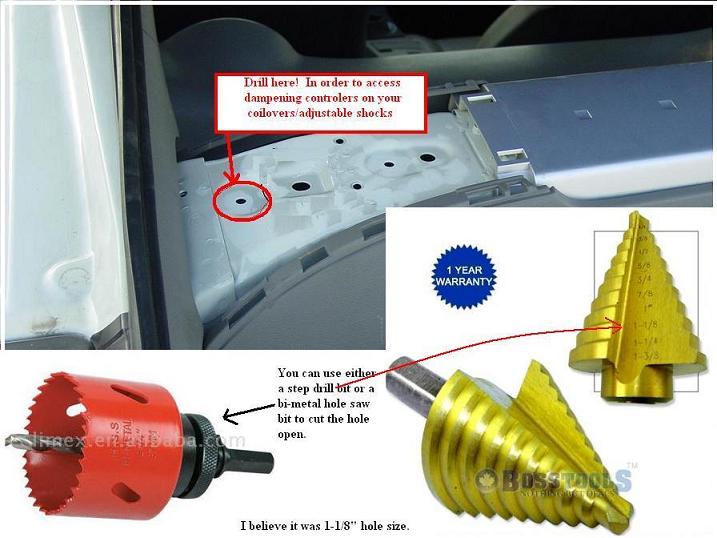

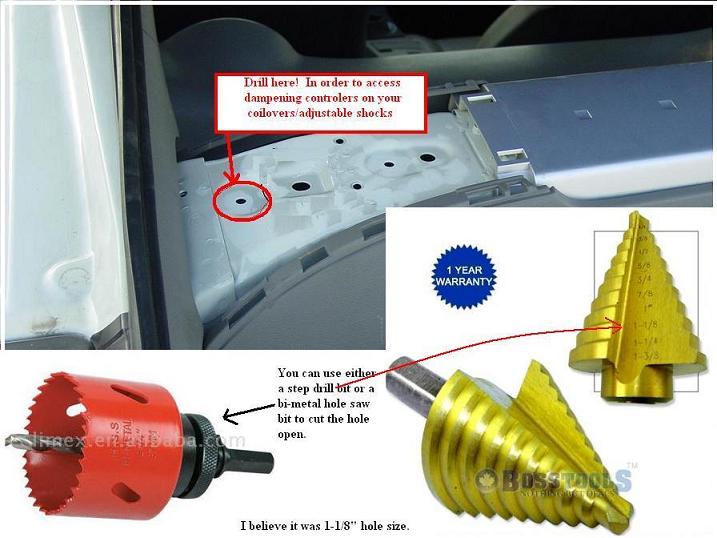

I know you can access the top of the rebound adjuster from this location, so im guessing that you can see the top of the welded studs from here as well.

Try cutting an access hole here. You can verify first if this is where you need to get into by putting a flash light to one of the other holes and peaking in.

Access hole:

From there, drill the hole up, whatever you need to do from the bottom and use that hole to gain access to drop the bolt down into. then from there use a ratchet with wobbles or a small wrench, etc to hold the head. maybe even bend a wrench if needed???

There is no need to then weld a plate or anything back over that hole - as that was originally designed to be a steel stamp punch out and was to remain open during the design phase of the 350z - original Nismo and track models were gonna have adjustable suspension, but was later cut due to cost savings.

-J

I know you can access the top of the rebound adjuster from this location, so im guessing that you can see the top of the welded studs from here as well.

Try cutting an access hole here. You can verify first if this is where you need to get into by putting a flash light to one of the other holes and peaking in.

Access hole:

From there, drill the hole up, whatever you need to do from the bottom and use that hole to gain access to drop the bolt down into. then from there use a ratchet with wobbles or a small wrench, etc to hold the head. maybe even bend a wrench if needed???

There is no need to then weld a plate or anything back over that hole - as that was originally designed to be a steel stamp punch out and was to remain open during the design phase of the 350z - original Nismo and track models were gonna have adjustable suspension, but was later cut due to cost savings.

-J

Last edited by JasonZ-YA; 08-27-2010 at 03:40 AM.

#51

Registered User

That sounds like a good way to fix it.

One concern is that welding on the car body may do strange things to the electronics. The welding and auto tech instructors at the local tech school won't let students doing any welding on late model cars with ECUs and such. At the least, I'd make sure the ground lead is on clean bare metal as close as possible to the repair.

Since you don't need a structural weld at this point, using JB Weld would probably work just as well, especially since you can always get to the top if you need to in the future.

One concern is that welding on the car body may do strange things to the electronics. The welding and auto tech instructors at the local tech school won't let students doing any welding on late model cars with ECUs and such. At the least, I'd make sure the ground lead is on clean bare metal as close as possible to the repair.

Since you don't need a structural weld at this point, using JB Weld would probably work just as well, especially since you can always get to the top if you need to in the future.

Last edited by winchman; 08-27-2010 at 04:10 AM.

#52

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

That sounds like a good way to fix it.

One concern is that welding on the car body may do strange things to the electronics. The welding and auto tech instructors at the local tech school won't let students doing any welding on late model cars with ECUs and such. At the least, I'd make sure the ground lead is on clean bare metal as close as possible to the repair.

Since you don't need a structural weld at this point, using JB Weld would probably work just as well, especially since you can always get to the top if you need to in the future.

One concern is that welding on the car body may do strange things to the electronics. The welding and auto tech instructors at the local tech school won't let students doing any welding on late model cars with ECUs and such. At the least, I'd make sure the ground lead is on clean bare metal as close as possible to the repair.

Since you don't need a structural weld at this point, using JB Weld would probably work just as well, especially since you can always get to the top if you need to in the future.

IF

- op drills access hole on top like i posted above and can access the top of the broken stud, he can drill a hole completely through and drop a bolt down through the hole.

tighten everything up and be done with it.

-J

#54

Registered User

iTrader: (1)

As above and also disconnect the battery ground. I've put two roll cages in 350Zs and have yet to fry an ECU or any other component on the car. Manufacturers do a lot of high volt, high amp testing to make their components don't get fried. Of course, nothing is foolproof.

#55

i finally got around replacing the stud today. it was much easier than i thought. i drilled a hole in the strut and then drilled out the broken stud. slipped in a m8x1.25 bolt rachet it down while holding a wrench to the top part of the bolt thru the struts. after all that, i place ample amount of jb weld on the top of the bolt. total time was like 1.5 hrs.

thanks for all the help guys. im glad i had so many options to choose from before i actually tackle the job.

thanks for all the help guys. im glad i had so many options to choose from before i actually tackle the job.

#56

Registered User

Great. Thanks for letting us know how it turned out.

I'm curious. How far was it from where you drilled the hole to the stud? Was my estimate of three inches about right?

I'm curious. How far was it from where you drilled the hole to the stud? Was my estimate of three inches about right?