Rear spindle/hub assembly bolt and bushing

#1

Registered User

Thread Starter

iTrader: (3)

Join Date: Nov 2006

Location: Virginia

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

Hey guys,

Tried to install aftermarket coilovers onto a 2003 350z but could not remove this bolt and bushing from the rear suspension

I believe its call rear spindle/hub assembly

Please let me know if anyone know the size of this bolt and where to order the bolt and the bushing

here's the picture!

Thanks!!

Tried to install aftermarket coilovers onto a 2003 350z but could not remove this bolt and bushing from the rear suspension

I believe its call rear spindle/hub assembly

Please let me know if anyone know the size of this bolt and where to order the bolt and the bushing

here's the picture!

Thanks!!

#3

Super Moderator

MY350Z.COM

MY350Z.COM

iTrader: (8)

Typically i would just take the bolt from the other side , measure and hit the hardware store for a new one.

#5

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

LOL........oh man...

VEE,

its just a bolt back there, remove the bolt from the head side, the nut is welded to the factory shock...

from there, usually the suspension that u purchase comes with ANOTHER nut to reuse that same bolt.

If not, You can easily replace the bolt with a M12x1.75 - 70mm long and then pair it with a "prevailing torque lock nut" or "top lock nut" to ensure it hold strong.

now, you also mentioned bushing??? what did you do? is the bushing damaged now from you cutting the bolt out or something???

if you need a new bushing there, you can see that whiteline makes a fairly inexpensive replacement for it ~45 bucks for a pair.

see here:

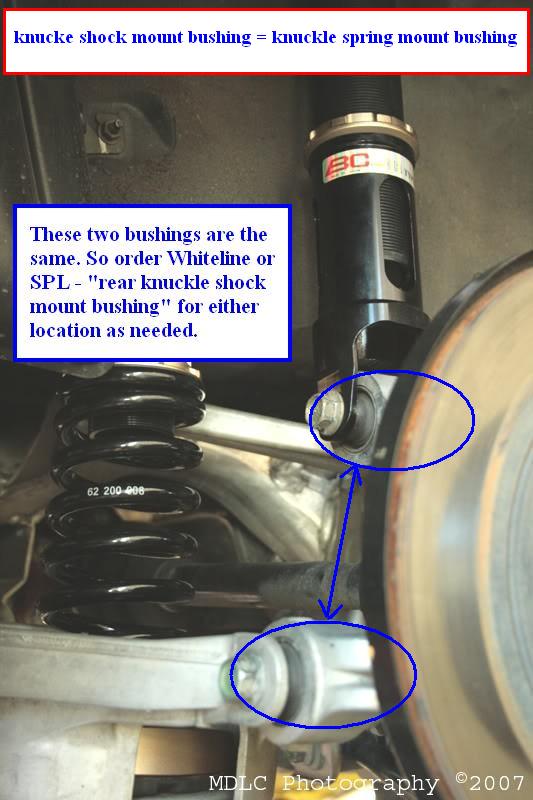

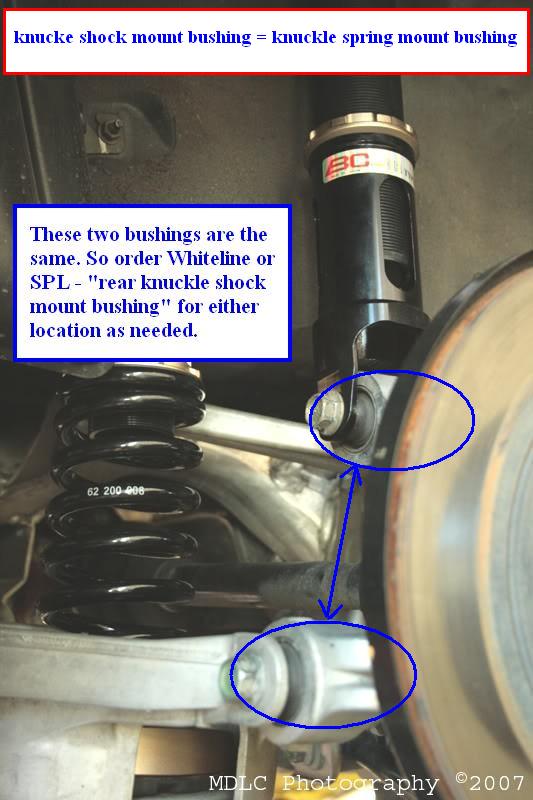

ALSO NOTE:

This took a bit of research as NO sites that sell these bushings clearly explain or even give part numbers for the spring bucket to knucke mount bushing location. But in case you need its the same bushing as the commonly listed "knuckle to shock mount bushing" that everyone replaces when going to coilovers. mainly those with true coilovers as thats the only point of mounting for them to rear suspension arms.

see here:

That bushing is the same for both locations - whiteline p/n is W62535 - if you notice on most sites, its the same price for those two, because they are the same. To install this whiteline bushing you need to go to a local steel yard and get a 1.5" DOM STEEL round stock with a .083 wall.

that results in a 1.33 Inner diameter that fits over the W62535 rear shock mount bushing perfectly:

that steel DOM shown will now be the driver for installing that bushing.

Taken from:

https://my350z.com/forum/8293650-post23.html

-J

VEE,

its just a bolt back there, remove the bolt from the head side, the nut is welded to the factory shock...

from there, usually the suspension that u purchase comes with ANOTHER nut to reuse that same bolt.

If not, You can easily replace the bolt with a M12x1.75 - 70mm long and then pair it with a "prevailing torque lock nut" or "top lock nut" to ensure it hold strong.

now, you also mentioned bushing??? what did you do? is the bushing damaged now from you cutting the bolt out or something???

if you need a new bushing there, you can see that whiteline makes a fairly inexpensive replacement for it ~45 bucks for a pair.

see here:

ALSO NOTE:

This took a bit of research as NO sites that sell these bushings clearly explain or even give part numbers for the spring bucket to knucke mount bushing location. But in case you need its the same bushing as the commonly listed "knuckle to shock mount bushing" that everyone replaces when going to coilovers. mainly those with true coilovers as thats the only point of mounting for them to rear suspension arms.

see here:

That bushing is the same for both locations - whiteline p/n is W62535 - if you notice on most sites, its the same price for those two, because they are the same. To install this whiteline bushing you need to go to a local steel yard and get a 1.5" DOM STEEL round stock with a .083 wall.

that results in a 1.33 Inner diameter that fits over the W62535 rear shock mount bushing perfectly:

that steel DOM shown will now be the driver for installing that bushing.

https://my350z.com/forum/8293650-post23.html

-J

#6

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

Install that bushing like this:

Rear knuckle bushing where shock/coilover attaches:

HF Ball joint tool: ~ $29.99 on sale Item 38335

26mm socket used to remove oem bushing:

Obviously this picture was taken after i took the bushing out to show that the socket fit well.

Mounted up:

I purchased HF long handle wrench set ITEM #47067 and used the 22mm wrench from the set. The beautiful thing about it was the angle the head had and the length for leverage in fighting the bushing out. Having the 22mm wrench made it EASY:

22mm long handle wrench from HF set used to turn da bish:

OEM BUSHING ON ITS WAY OUT ~ FALLING INTO RECEIVING STEEL CUP:

OUT:

However, notice how this side of the rear knuckle is machines FLAT!

Well, the opposite side is NOT flat and is angled at about a 5 degree angle.

~ Sorry, I didn't get a picture of this ~ but I then found a larger piece of steel and cut one side of it at a five degree angle with my chop saw to help line up the ball joint tool STRAIGHT!

Notice how this side is angled at 5 degrees, and how the black receiving cup isn't straight:

I replaced the black steel cup with another larger piece of steel, cut one side at a 5 degree angle and then when i rigged the entire ball joint tool back up everything lined up great and bushing pressed in easy on the first time!

Steel needed to install the whiteline bushing in:

To install this whiteline W62535 bushing you need to go to a local steel yard and get a Overal diameter 1.5" DOM STEEL round stock with a .083 wall.

That results in a 1.5-.083-.083 = 1.33" Inner diameter that fits over the W62535 rear shock mount bushing perfectly:

New Whiteline P/N W62535 bushing installed:

-J

HF Ball joint tool: ~ $29.99 on sale Item 38335

26mm socket used to remove oem bushing:

Obviously this picture was taken after i took the bushing out to show that the socket fit well.

Mounted up:

I purchased HF long handle wrench set ITEM #47067 and used the 22mm wrench from the set. The beautiful thing about it was the angle the head had and the length for leverage in fighting the bushing out. Having the 22mm wrench made it EASY:

22mm long handle wrench from HF set used to turn da bish:

OEM BUSHING ON ITS WAY OUT ~ FALLING INTO RECEIVING STEEL CUP:

OUT:

However, notice how this side of the rear knuckle is machines FLAT!

Well, the opposite side is NOT flat and is angled at about a 5 degree angle.

~ Sorry, I didn't get a picture of this ~ but I then found a larger piece of steel and cut one side of it at a five degree angle with my chop saw to help line up the ball joint tool STRAIGHT!

Notice how this side is angled at 5 degrees, and how the black receiving cup isn't straight:

I replaced the black steel cup with another larger piece of steel, cut one side at a 5 degree angle and then when i rigged the entire ball joint tool back up everything lined up great and bushing pressed in easy on the first time!

Steel needed to install the whiteline bushing in:

To install this whiteline W62535 bushing you need to go to a local steel yard and get a Overal diameter 1.5" DOM STEEL round stock with a .083 wall.

That results in a 1.5-.083-.083 = 1.33" Inner diameter that fits over the W62535 rear shock mount bushing perfectly:

New Whiteline P/N W62535 bushing installed:

-J

Last edited by JasonZ-YA; 06-27-2012 at 05:38 AM. Reason: updated this thread pics and process of how to

Trending Topics

#8

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

UPDATE:

found pic:

-J

Last edited by JasonZ-YA; 06-27-2012 at 04:21 AM.

#9

Registered User

Join Date: Apr 2014

Location: Medicine Hat, Ab

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

06 350z and my bushing decided to spin with my bushings on both sides had to use a cutting wheel and carefully grind them off without cutting the hub. Just wondering if this has happened to anyone else?

#11

Registered User

Good luck! Mine never came apart. I replaced all shocks last year. Put PB plaster on everything for a week. After patiently trying tricks I know for over an hour, I finally cut the bottom of the shock off with an air cutting wheel and still have the bolt in the sleeve from the bushing on my work bench to this day as a trophy.

The bolt passes through one side of the shock, through the bushing, and threads into the other side of the shock fork.

After I cut the shock fork it still took an hour of destroying the bushing with an impact wrench for it to let go of the sleeve. I twisted the mess over and over until the rubber let go, then had to press the OEM sleeve out. Be warned that you have no real leverage to get the bolt out of the inner sleeve without really twisting the rubber of the bushing and before you know it, it will start to tear. Try to use a clamp setup like shown to press the bolt out if you have room before you try any twisting or pulling. The only resistance you have to fighting the bolt out of the sleeve is the strength that is left in the rubber. If you are not replacing the shock you will have much more trouble since you won't want to cut it!

I've tried two more times for fun in a vice with other methods and it is corroded together one piece still. Never budged at all. Be prepared for the worst. Be very patient and you may get lucky. Be conservative if you heat up anything with a torch. I feel your pain. May have to take it to a pro and let them deal with it.

I cannot tell from your description if the bolt is stuck on the sleeve which would be very common or that the threads are rusted into the fork. Either way think things through before you do them.

I replaced mine with Whiteline. I have several other Whiteline bushings on my car that slipped right in, but the one for this position was OVERSIZED. It was crazy like 0.005 to 0.008" over a press fit from what I remember. To get it to fit I had to sand it down for an hour to get it to press in.

It is a real trick to get the new bushing to start straight. Be careful with that too.If you get to the point that you are trying to put it in, once it starts a little and won't keep going in, pull it back out and inspect the bore on the arm to make sure you are not digging into the bore with the leading edge of the bushing. It can easily do that with the angle involved. If you nick it, smooth it out with some sandpaper and try again because you will keep hitting the same groove if you don't repair it. Take baby steps and you won't have much if any to repair.

Personally after all that I feel lucky because if I wasn't planning on upgrading the bushing I would not have had one on hand for when I had no choice but to destroy the OEM. This was on the right hand side which sees most of the road grime and salt in the winter. The left side was difficult but came out without destroying it.

The bolt passes through one side of the shock, through the bushing, and threads into the other side of the shock fork.

After I cut the shock fork it still took an hour of destroying the bushing with an impact wrench for it to let go of the sleeve. I twisted the mess over and over until the rubber let go, then had to press the OEM sleeve out. Be warned that you have no real leverage to get the bolt out of the inner sleeve without really twisting the rubber of the bushing and before you know it, it will start to tear. Try to use a clamp setup like shown to press the bolt out if you have room before you try any twisting or pulling. The only resistance you have to fighting the bolt out of the sleeve is the strength that is left in the rubber. If you are not replacing the shock you will have much more trouble since you won't want to cut it!

I've tried two more times for fun in a vice with other methods and it is corroded together one piece still. Never budged at all. Be prepared for the worst. Be very patient and you may get lucky. Be conservative if you heat up anything with a torch. I feel your pain. May have to take it to a pro and let them deal with it.

I cannot tell from your description if the bolt is stuck on the sleeve which would be very common or that the threads are rusted into the fork. Either way think things through before you do them.

I replaced mine with Whiteline. I have several other Whiteline bushings on my car that slipped right in, but the one for this position was OVERSIZED. It was crazy like 0.005 to 0.008" over a press fit from what I remember. To get it to fit I had to sand it down for an hour to get it to press in.

It is a real trick to get the new bushing to start straight. Be careful with that too.If you get to the point that you are trying to put it in, once it starts a little and won't keep going in, pull it back out and inspect the bore on the arm to make sure you are not digging into the bore with the leading edge of the bushing. It can easily do that with the angle involved. If you nick it, smooth it out with some sandpaper and try again because you will keep hitting the same groove if you don't repair it. Take baby steps and you won't have much if any to repair.

Personally after all that I feel lucky because if I wasn't planning on upgrading the bushing I would not have had one on hand for when I had no choice but to destroy the OEM. This was on the right hand side which sees most of the road grime and salt in the winter. The left side was difficult but came out without destroying it.

Last edited by bjr; 05-07-2014 at 06:52 AM.

Thread

Thread Starter

Forum

Replies

Last Post

Lt_Ballzacki

Brakes & Suspension

39

08-06-2021 06:19 AM