DIY - Solid diff bushing install - No subframe drop method, no c clamp either!

#181

New Member

iTrader: (13)

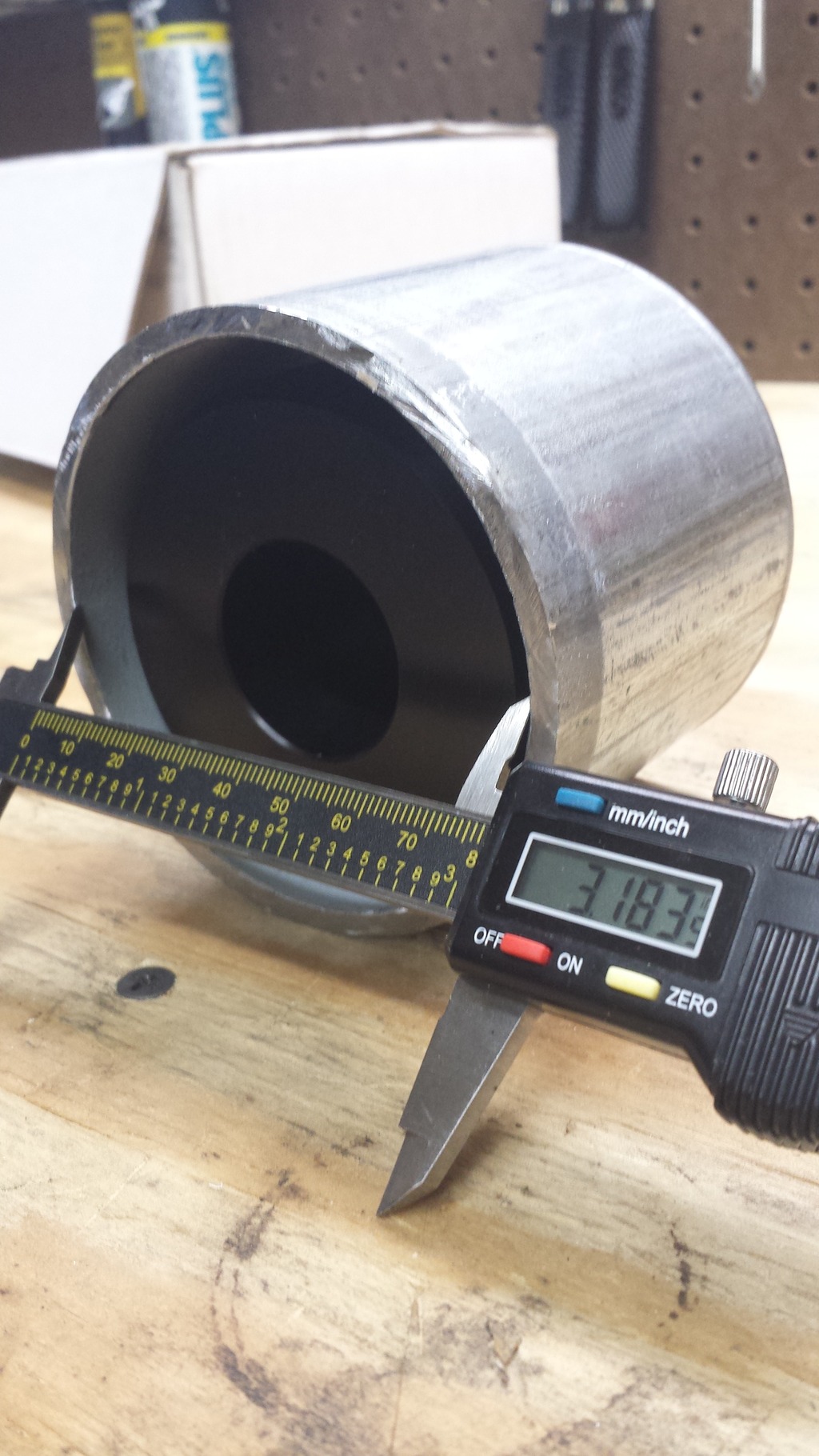

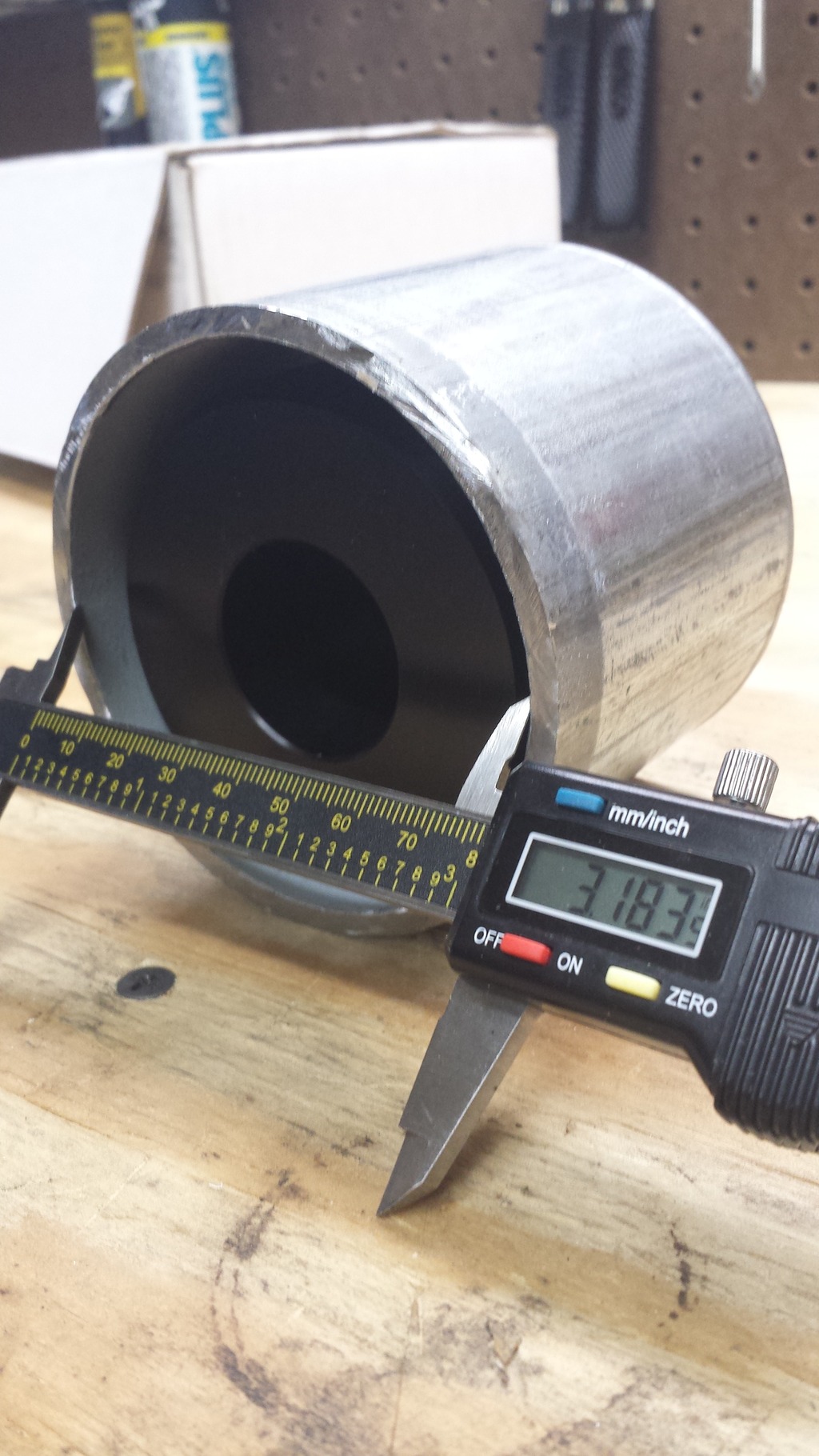

I'm about to do this job. I picked up for free at my local steel yard a piece of metal pipe that is large enough to accept the SPL bushing when I press out. The only potential problem is the inner diameter is only slighty larger than the bushing and it will sit on the "metal ring" welded to the subframe and not the subframe itself? Am I ok to use this and press on this welded ring when removing the OEM bearing? Picture of the welded ring is at the bottom. Thanks.

786e67d7.jpg?t=1280769185

786e67d7.jpg?t=1280769185

Last edited by labelworkshop75; 06-08-2015 at 04:48 PM.

#185

Just finished installing the diff ear bushings and the one in the subframe. Any advice on reinstallation to make my life easier?

Also how far in should the subframe bushing go? mine is almost flush on the side thats closest to the front of the car

Also how far in should the subframe bushing go? mine is almost flush on the side thats closest to the front of the car

#188

New Member

iTrader: (13)

Some tips that worked for me:

I used the large franken socket method.

1: I duct taped the metal plate on top of the 4" diameter metal pipe instead of welding.

2: I had some "all thread" from Lowes in my garage already

3: I used this in combination with the SPL press plate and used my impact gun on it. The sub frame bushing came right out. EASY.

4: I experimented by drilling a hole in the rubber first. I do not recommend doing this. I got blasted in the eyes with black goo. Just like Newman:

5. I used a 32MM socket and hammered out the ear bushing. Very easy. The 32mm was not quite large enough on one ear, so I walked it around the edges and tap it out evenly.

6: I freezed my bushings.

7: Hardest part for me was installing the new SPL sub frame bushing. I hammered the hell out of it (used PB blaster in the hole and on the bushing). I would recommend the franken socket method to reinstall.

I used the large franken socket method.

1: I duct taped the metal plate on top of the 4" diameter metal pipe instead of welding.

2: I had some "all thread" from Lowes in my garage already

3: I used this in combination with the SPL press plate and used my impact gun on it. The sub frame bushing came right out. EASY.

4: I experimented by drilling a hole in the rubber first. I do not recommend doing this. I got blasted in the eyes with black goo. Just like Newman:

6: I freezed my bushings.

7: Hardest part for me was installing the new SPL sub frame bushing. I hammered the hell out of it (used PB blaster in the hole and on the bushing). I would recommend the franken socket method to reinstall.

Last edited by labelworkshop75; 06-28-2015 at 10:51 AM.

#190

For anyone considering doing these, here's some great pricing on the kit:

Amazon.com: Solid bushings-SPL SOLID Differential Bushings, 03-08 Nissan 350Z (Z33) and 03-06 Infiniti G35 Sedan: Automotive

Amazon.com: Solid bushings-SPL SOLID Differential Bushings, 03-08 Nissan 350Z (Z33) and 03-06 Infiniti G35 Sedan: Automotive

Jason - we went cheap initially, and installed a poly bushing; it failed in less than one year. I now have the SPL center bushing (and a replacement Whiteline) that I want to install this weekend. Do you think if I take the load off the failed bushing, I can slip it out and simply slip in a frozen SPL (I doubt it)? What about the Whiteline?

Jason - we went cheap initially, and installed a poly bushing; it failed in less than one year. I now have the SPL center bushing (and a replacement Whiteline) that I want to install this weekend. Do you think if I take the load off the failed bushing, I can slip it out and simply slip in a frozen SPL (I doubt it)? What about the Whiteline?

The following users liked this post:

scotts300 (07-23-2015)

#192

Update: the old torn Whiteline bushing came out easily once I removed the rear bolt and took the load off it. I did not need to remove the pumpkin. I have a replacement Whiteline as well as a solid SPL, so I thought I'd give the spl a go. I froze it overnight, and slid it in. It only went in about 1/4". I lubed it up and tried again, now with some gentle mallet taps. It went in a little more but stopped, and now it's stuck from moving in either direction. Aside from pulling the pumpkin and pulling it in from the backside, does anyone have any good ideas for moving it in either direction at this point? It's back to room temp, so likely even more stuck now.

#194

New Member

Update: the old torn Whiteline bushing came out easily once I removed the rear bolt and took the load off it. I did not need to remove the pumpkin. I have a replacement Whiteline as well as a solid SPL, so I thought I'd give the spl a go. I froze it overnight, and slid it in. It only went in about 1/4". I lubed it up and tried again, now with some gentle mallet taps. It went in a little more but stopped, and now it's stuck from moving in either direction. Aside from pulling the pumpkin and pulling it in from the backside, does anyone have any good ideas for moving it in either direction at this point? It's back to room temp, so likely even more stuck now.

The following 2 users liked this post by scotts300:

F2CMaDMaXX (07-27-2015),

superlim9 (07-26-2015)

#196

Registered User

Join Date: May 2013

Location: san antonio

Posts: 46

Likes: 0

Received 0 Likes

on

0 Posts

Would it be fine to keep the SPL bushings on dry ice over night?

edit. didnt realize dry ice only lasts 4 hrs per pound. better off grabbing it in the morning instead of overnight.

edit. didnt realize dry ice only lasts 4 hrs per pound. better off grabbing it in the morning instead of overnight.

Last edited by 03s2kman; 08-05-2015 at 08:31 PM.

#198

Registered User

Yesterday I installed my whiteline bushings. Jesus God, what a nightmare. Nothing went smoothly. On my own it took me about 12 hours. Now that everything's dropped in I have an audible pop on take off and when going into 2. Anyone else experience this? Plus, the subframe bushing nut doesn't seem to be torqueing down. Its on the stud a ways but it's only slightly tighter than finger. After yesterday, bending over at the dealership doesn't seem like such a bad idea.

#200

Registered User

UPDATE: I've ordered a new diff stud and nut just incase the old one has gone kaput. With the car in first just by rolling it back and forth by hand you can see the diff move up and down creating the popping sound. Thankfully, a guy I know is going to help out when the parts come in; so it should be all sorted in the next week or so. I'm confident... ish. Thankfully it's not my DD so it's not a huge inconvenience. I'll update when we try to solve it.