How to do Twins right the first time!!!

#1

Registered User

Thread Starter

How to do Twins right the first time!!!

Okay, first of all I am talking about Twin Turbos, not doing "twins". There's other websites for that

Or for that matter, doing forced induction right the first time whether its a single turbo or SC.

Now, some background...as many of us Z owners striving to seek more and more power out of our stock engine, I decided to buy a GReddy TT kit. Had it professionally installed and about a month later...catatrophic engine damage. I broke connecting rod #2 and subsequently it put two windows in my block. So, I decided do it right and do a forged internal build up and I am only days away from finally have it done. But this thread is not about MY build up, its about YOUR build up. I have put together a good plan on how to go about an engine build up AND forced induction to your Z.

First, the price of admission. For those of you that would like to go Venture in the land of boost, the price of admission is a steep one....but well worth the cost!!!

If I had to do it all over....to minimize the time your Z is in the shop and to minimize the TOTAL labor costs and not risking blowing an engine...

I would buy the following in this order...

Buy the following in this order...

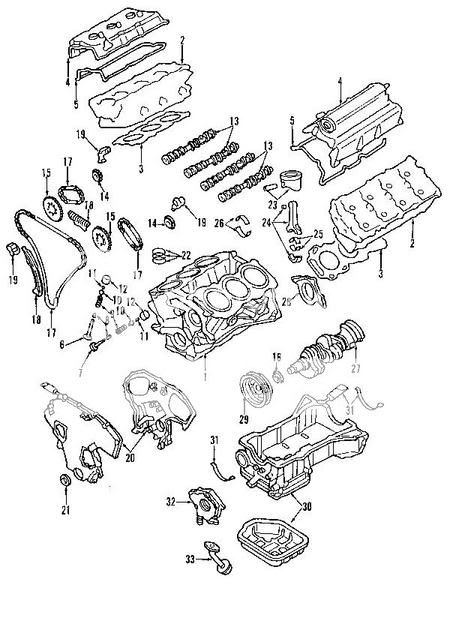

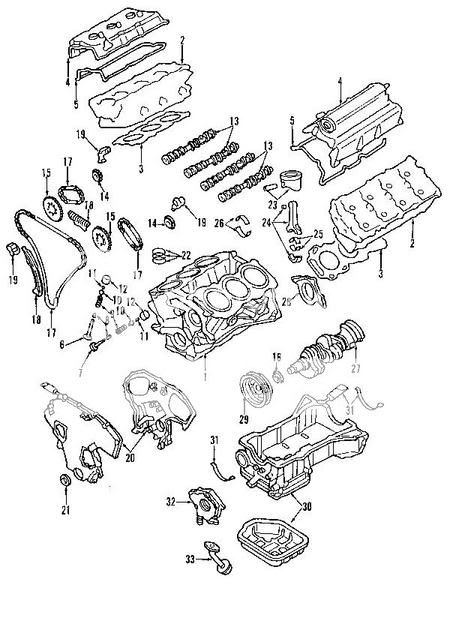

1. A short block, this is basically just an engine w/o heads and a crank. See item 1. Since the block is brand new, you don't have to worry about buying a used short block and how it became a used short block. Believe or not, the small block will cost only about 1300. I say only, because this will become your build up engine. From here, you can sleeve it with AEBS only if you plan to exceed 600rwhp. Once you're reaching these power levels, you are in uncharted terroritory that less than a handful have ventured into. This of course will be inherently risky to venture where no one else has any experience.

2. Next, you buy a crankshaft. item 27. This will cost you about 550. Now, that you have a block and crank, you can get the bearing codes for the rods and mains and...

3. Buy the 12 rod bearings item 25 (there sold in halves) and order the 4 main bearings. This will only set you back about 200. You got off easy in this step. But there's more...

4. Now, pistons and rods. You shouldn't spend more than 2k here if you shop around. My suggestion would be to stay less than 9.5:1 compression ratio. In the simplest terms here...the lower the compression ratio, the higher psi you can run. The trade off, there would be a little more of a delay in reaching your peak hp in your power band. But, you will be less likely to run into detonation issues. Personally, I wanted 9:1, but ended up with 8.6:1 due to supply issues of pistons.

5. Okay, now you have a short block, crank, rods, bearings, and pistons. But a couple more internal parts to buy, ARP head studs and main studs. These should run you about 450 for the studs. There are 16 head studs and 16 main studs.

Now, you have reached a point where you can ship these parts to a reputable builder and they can build your engine. Make sure this shop has built one before and their machine shop has worked on a VQ-35DE. THIS IS CRUICIAL.

Now they can double check the clearances of your bearings and you have a "built" bottom end engine. One more thing to possibly consider in this step is to get a thermo coat on your pistons and bearings. There is debate on the longevity of the coat, but it doesn't cost too much though. Whats another few hundred bucks.

6. Okay, now this is the step, not step 1, is when you buy your favorite TT or single Turbo or Super charger that you have been having dirty fantasies about when no one is looking. Depending on the brand, each will have something or another you must buy separately. If you've made it this far, you would have researched the shortcomings of your particuler kit. At this point you should consider thermo coating your turbo exhaust manifolds and exhaust turbine. This will allow you to keep engine temps down and keep the hot gases inside hot.

7. Now, you are in a really good position to start your build. But, a few more things to buy...of course. There's always something else to buy! But, the good news is that the remainder of the stuff is usually kept in stock.

NGk plugs...75

boost controller...450

Gauges....300-1200 (depending on number and type, + install)

Clutch....1k-2k (depending on brand, and you might as well do it while the engine is out)

Fuel sys upgrade...1k (or it you get APS, its in the price tag already)

Larger fuel injectors...500

Thermal coating.....300 This could be on pistons, bearings, or turbo "hot" parts

8. Once you get back your "built" engine, which would probably take 6-8 weeks if you're lucky. You can now drop off your Z at a good and reputable shop, and they can swap out the engines and install your TT at the same time. MAKE SURE YOU GET A GOOD ESTIMATE OF ALL COSTS INVOLVED AND GET IT IN WRITING ALONG WITH A COMPLETION DATE!!! Okay, enough with the yelling, lets continue. From here, this should take less than a month. So, your Z sat in a shop for less than a month and you have a built engine with TT. AND you were able to minimize downtime, costs, and you even spread out the costs of buying parts and the TT. Labor costs of pulling and swapping your engine and installing your TTs, is now cheaper than doing those items separately.

9. What do you do with your original short block? No, it does not become a new table in your nook by your kitchen!!! You will be able to sell it to the next guy. And he can still follow the plan I just laid out.

10. So, you read this far and now you are thinking I'm nuts or maybe the price of admission is very high. Well, you're right on both accounts. No, but seriously, this is the best way to go about it especially if....

a. You don't want to have your Z in a shop for 2-3 MONTHS

b. Your Z is a daily driver

c. Dont think you can take a short cut and just do TTs on stock internals. Come on now, that engine puts down 235rwhp and not designed to handle 350+rwhp!

d. You can't wait to read my kill stories again. Sorry, got off topic.

Now for the short list, yes it does exists. If you don't want to listen to the advice above, at least buy these at the bare minimum:

Connecting rods

Pistons

ARP Main studs/Head studs

Rod+Main, Bearings

Overhaul Gasket Kit

Rear Main Oil Seal

NGK one step colder plugs

Boost gauge

Oil Press gauge

EGT Gauge

AFR gauge

Clutch Upgraded

And the following depending on boost levels:

AAM Fuel Return System

Bigger fuel injectors

Okay, you survived reading my post. I hope I have taught you a couple of things along the way and as always I more than welcome questions, comments, corrections, and money. J/K. We are all here to learn about those wonderful little money pits we call "Our Zs".

Okay, first of all I am talking about Twin Turbos, not doing "twins". There's other websites for that

Or for that matter, doing forced induction right the first time whether its a single turbo or SC.

Now, some background...as many of us Z owners striving to seek more and more power out of our stock engine, I decided to buy a GReddy TT kit. Had it professionally installed and about a month later...catatrophic engine damage. I broke connecting rod #2 and subsequently it put two windows in my block. So, I decided do it right and do a forged internal build up and I am only days away from finally have it done. But this thread is not about MY build up, its about YOUR build up. I have put together a good plan on how to go about an engine build up AND forced induction to your Z.

First, the price of admission. For those of you that would like to go Venture in the land of boost, the price of admission is a steep one....but well worth the cost!!!

If I had to do it all over....to minimize the time your Z is in the shop and to minimize the TOTAL labor costs and not risking blowing an engine...

I would buy the following in this order...

Buy the following in this order...

1. A short block, this is basically just an engine w/o heads and a crank. See item 1. Since the block is brand new, you don't have to worry about buying a used short block and how it became a used short block. Believe or not, the small block will cost only about 1300. I say only, because this will become your build up engine. From here, you can sleeve it with AEBS only if you plan to exceed 600rwhp. Once you're reaching these power levels, you are in uncharted terroritory that less than a handful have ventured into. This of course will be inherently risky to venture where no one else has any experience.

2. Next, you buy a crankshaft. item 27. This will cost you about 550. Now, that you have a block and crank, you can get the bearing codes for the rods and mains and...

3. Buy the 12 rod bearings item 25 (there sold in halves) and order the 4 main bearings. This will only set you back about 200. You got off easy in this step. But there's more...

4. Now, pistons and rods. You shouldn't spend more than 2k here if you shop around. My suggestion would be to stay less than 9.5:1 compression ratio. In the simplest terms here...the lower the compression ratio, the higher psi you can run. The trade off, there would be a little more of a delay in reaching your peak hp in your power band. But, you will be less likely to run into detonation issues. Personally, I wanted 9:1, but ended up with 8.6:1 due to supply issues of pistons.

5. Okay, now you have a short block, crank, rods, bearings, and pistons. But a couple more internal parts to buy, ARP head studs and main studs. These should run you about 450 for the studs. There are 16 head studs and 16 main studs.

Now, you have reached a point where you can ship these parts to a reputable builder and they can build your engine. Make sure this shop has built one before and their machine shop has worked on a VQ-35DE. THIS IS CRUICIAL.

Now they can double check the clearances of your bearings and you have a "built" bottom end engine. One more thing to possibly consider in this step is to get a thermo coat on your pistons and bearings. There is debate on the longevity of the coat, but it doesn't cost too much though. Whats another few hundred bucks.

6. Okay, now this is the step, not step 1, is when you buy your favorite TT or single Turbo or Super charger that you have been having dirty fantasies about when no one is looking. Depending on the brand, each will have something or another you must buy separately. If you've made it this far, you would have researched the shortcomings of your particuler kit. At this point you should consider thermo coating your turbo exhaust manifolds and exhaust turbine. This will allow you to keep engine temps down and keep the hot gases inside hot.

7. Now, you are in a really good position to start your build. But, a few more things to buy...of course. There's always something else to buy! But, the good news is that the remainder of the stuff is usually kept in stock.

NGk plugs...75

boost controller...450

Gauges....300-1200 (depending on number and type, + install)

Clutch....1k-2k (depending on brand, and you might as well do it while the engine is out)

Fuel sys upgrade...1k (or it you get APS, its in the price tag already)

Larger fuel injectors...500

Thermal coating.....300 This could be on pistons, bearings, or turbo "hot" parts

8. Once you get back your "built" engine, which would probably take 6-8 weeks if you're lucky. You can now drop off your Z at a good and reputable shop, and they can swap out the engines and install your TT at the same time. MAKE SURE YOU GET A GOOD ESTIMATE OF ALL COSTS INVOLVED AND GET IT IN WRITING ALONG WITH A COMPLETION DATE!!! Okay, enough with the yelling, lets continue. From here, this should take less than a month. So, your Z sat in a shop for less than a month and you have a built engine with TT. AND you were able to minimize downtime, costs, and you even spread out the costs of buying parts and the TT. Labor costs of pulling and swapping your engine and installing your TTs, is now cheaper than doing those items separately.

9. What do you do with your original short block? No, it does not become a new table in your nook by your kitchen!!! You will be able to sell it to the next guy. And he can still follow the plan I just laid out.

10. So, you read this far and now you are thinking I'm nuts or maybe the price of admission is very high. Well, you're right on both accounts. No, but seriously, this is the best way to go about it especially if....

a. You don't want to have your Z in a shop for 2-3 MONTHS

b. Your Z is a daily driver

c. Dont think you can take a short cut and just do TTs on stock internals. Come on now, that engine puts down 235rwhp and not designed to handle 350+rwhp!

d. You can't wait to read my kill stories again. Sorry, got off topic.

Now for the short list, yes it does exists. If you don't want to listen to the advice above, at least buy these at the bare minimum:

Connecting rods

Pistons

ARP Main studs/Head studs

Rod+Main, Bearings

Overhaul Gasket Kit

Rear Main Oil Seal

NGK one step colder plugs

Boost gauge

Oil Press gauge

EGT Gauge

AFR gauge

Clutch Upgraded

And the following depending on boost levels:

AAM Fuel Return System

Bigger fuel injectors

Okay, you survived reading my post. I hope I have taught you a couple of things along the way and as always I more than welcome questions, comments, corrections, and money. J/K. We are all here to learn about those wonderful little money pits we call "Our Zs".

Last edited by going deep; 03-02-2005 at 10:58 PM.

The following users liked this post:

Jozeey_ (08-13-2021)

#5

Sponsor

builtZmotors

builtZmotors

iTrader: (21)

Join Date: Jul 2004

Location: Albuquerque, NM

Posts: 2,780

Likes: 0

Received 0 Likes

on

0 Posts

ernie:

if i could do it over again, I would send out the forged internals and maybe even all of the hardware to be cryogenically frozen (not for hopes of future scientists being able to bring them back to life) ...but to further strengthen the metals

TODD

if i could do it over again, I would send out the forged internals and maybe even all of the hardware to be cryogenically frozen (not for hopes of future scientists being able to bring them back to life) ...but to further strengthen the metals

TODD

#6

Sponsor

Forged Performance

Forged Performance

iTrader: (92)

Another excellent write up.

PS: I am renting out my torque plate if anyone is interested. I paid dearly for it.

PM me if interested.

Also, Moly is a good idea of the piston skirts. But if you decide to coat the tops of the pistons, its recommennded that you do the entire combustion chamber as well. Valves, head combustion pocket. Otherwise, the heat will deflect from the coated pistons, and wreak havoc on your uncoated valves.

PS: I am renting out my torque plate if anyone is interested. I paid dearly for it.

PM me if interested.

Also, Moly is a good idea of the piston skirts. But if you decide to coat the tops of the pistons, its recommennded that you do the entire combustion chamber as well. Valves, head combustion pocket. Otherwise, the heat will deflect from the coated pistons, and wreak havoc on your uncoated valves.

Trending Topics

#9

Registered User

iTrader: (1)

Join Date: May 2002

Location: San Diego

Posts: 1,232

Likes: 0

Received 0 Likes

on

0 Posts

Great write-up, but keep in mind that SGP sells built short and long blocks that have pretty much everything you covered, and they are reasonably priced when compared to buying the parts and paying a builder to put them together (SGP Built VQs).

Ordering from them would definatly cut down on your car's down time, and they do know a thing or two about Nissans.

Ordering from them would definatly cut down on your car's down time, and they do know a thing or two about Nissans.

#10

Registered User

Thread Starter

Originally posted by gq_626

Another excellent write up.

PS: I am renting out my torque plate if anyone is interested. I paid dearly for it.

PM me if interested.

Also, Moly is a good idea of the piston skirts. But if you decide to coat the tops of the pistons, its recommennded that you do the entire combustion chamber as well. Valves, head combustion pocket. Otherwise, the heat will deflect from the coated pistons, and wreak havoc on your uncoated valves.

Another excellent write up.

PS: I am renting out my torque plate if anyone is interested. I paid dearly for it.

PM me if interested.

Also, Moly is a good idea of the piston skirts. But if you decide to coat the tops of the pistons, its recommennded that you do the entire combustion chamber as well. Valves, head combustion pocket. Otherwise, the heat will deflect from the coated pistons, and wreak havoc on your uncoated valves.

#11

Registered User

iTrader: (1)

Join Date: Feb 2003

Location: VA

Posts: 432

Likes: 0

Received 0 Likes

on

0 Posts

Seriously - thank you very, very much.

This is exactly the type of thing I've been looking for for quite some time.

One of the (many) reasons for me not being ready to go FI is the lack of a concise, step 1/2/3/4/5 type explanation. Not sayings its not out there - just that this the first I've seen. Thanks again!

ahm

This is exactly the type of thing I've been looking for for quite some time.

One of the (many) reasons for me not being ready to go FI is the lack of a concise, step 1/2/3/4/5 type explanation. Not sayings its not out there - just that this the first I've seen. Thanks again!

ahm

#13

Sponsor

builtZmotors

builtZmotors

iTrader: (21)

Join Date: Jul 2004

Location: Albuquerque, NM

Posts: 2,780

Likes: 0

Received 0 Likes

on

0 Posts

Originally posted by JonathanG35

could you describe balancing and blueprinting and their importance in a built motor?

could you describe balancing and blueprinting and their importance in a built motor?

now, back to rebuilding a motor and the importance of balancing and blueprinting...

balancing refers to making sure the rotating assembly-the crank, connecting rods, and the pistons are all within specs..

the rods need to be balanced to one another-meaning the weights will differ just a bit straight from production, so re-checking them and shaving off an extremely ammount of material on some of the heavier rods will help get them all to the same weight.

the pistons, the same...then figuring out the ratio of weight between the pistons and rods combined to the crank-0-for the vq, that number is 50%...

to finish the balancing process, the entire rotating assembly is turned on a jig-type of dealy and the crank is shaved down here and there (or even small amounts of metal added)-to ensure the smoothest rotating assembly possible

(BTW, if I left anything out or explained something weird, pls anyone, jump in and clarify...I am learning as well!)

Blueprinting refers to making sure evrything is fitted to extremely tight tolerances--meaning the main bearings are within xxx amount on each of the 4 crank journals (where the crank articulates w/ the block)...same with the rod bearings...torquing everything down to factory specification...basically a balanced and blueprinted motor should be better than factory in its clearances!

I'm tired of typing, so please, if anyone else can add of clean up my explanation-much appreciated for my learning progress!!!

#14

Turbo Whore

iTrader: (4)

Join Date: Oct 2002

Location: West suburbs of Chi-town

Posts: 7,303

Likes: 0

Received 1 Like

on

1 Post

one thing that nobody has mentioned as of yet is stock bore vs. overbore and what the significance of each is as far as the pistons are concerned. For example....if someone was to use a used short block, it would be advisable to use overbore pistons and have the block machined before starting the build.

Anyone that knows more than I do please feel free to elaborate.

Anyone that knows more than I do please feel free to elaborate.

#15

Sponsor

builtZmotors

builtZmotors

iTrader: (21)

Join Date: Jul 2004

Location: Albuquerque, NM

Posts: 2,780

Likes: 0

Received 0 Likes

on

0 Posts

right!

in ernie's suggestion of buying a new block and new crank and sleeving the block (personally, i would buy a used shortblock if i was gonna go through the process of having it resleaved), the new sleaves would be to the specified bore

if building up a brand new block: stock sized (no overbore) lower CR forged pistons (for example:arias)-no machine work

if using a used block, overbore .02 to clean up the cylinders..someone said before this only ups the displacement from 3.5 to 3.54...

so there!

in ernie's suggestion of buying a new block and new crank and sleeving the block (personally, i would buy a used shortblock if i was gonna go through the process of having it resleaved), the new sleaves would be to the specified bore

if building up a brand new block: stock sized (no overbore) lower CR forged pistons (for example:arias)-no machine work

if using a used block, overbore .02 to clean up the cylinders..someone said before this only ups the displacement from 3.5 to 3.54...

so there!

#16

Sponsor

Forged Performance

Forged Performance

iTrader: (92)

It's important to always use overbore pistons if possible. Nissan fits the pistons to the cylinders, meaning, each cylinder will be a slightly different diameter...even if buying a brand new block. It's important to get .020 overbore pistons so the machine shop can machine each cylinder to the piston, with goal of having precisly .030 piston to wall clearance (in the case of Arias pistons).

Each piston manufacturer has their recommended piston to wall clearance.

Each piston manufacturer has their recommended piston to wall clearance.

#18

Registered User

Thread Starter

Originally posted by 350zDCalb

Basically, any motor off the factory assembly line can be within a wide range of sloppy tolerances, meaning a motor can go out one day that has great fitment and tight clearances and the next day another assembly line motor can be at the high range of the allowed tolerances, resulting in a motor that is just a hair less productive in power and wear and tear than the next. You would probably never know that you had one of these "sloppy" motors unless you really pushed its limits (like forced induction on a naturally aspirated motor)...

now, back to rebuilding a motor and the importance of balancing and blueprinting...

balancing refers to making sure the rotating assembly-the crank, connecting rods, and the pistons are all within specs..

the rods need to be balanced to one another-meaning the weights will differ just a bit straight from production, so re-checking them and shaving off an extremely ammount of material on some of the heavier rods will help get them all to the same weight.

the pistons, the same...then figuring out the ratio of weight between the pistons and rods combined to the crank-0-for the vq, that number is 50%...

to finish the balancing process, the entire rotating assembly is turned on a jig-type of dealy and the crank is shaved down here and there (or even small amounts of metal added)-to ensure the smoothest rotating assembly possible

(BTW, if I left anything out or explained something weird, pls anyone, jump in and clarify...I am learning as well!)

Blueprinting refers to making sure evrything is fitted to extremely tight tolerances--meaning the main bearings are within xxx amount on each of the 4 crank journals (where the crank articulates w/ the block)...same with the rod bearings...torquing everything down to factory specification...basically a balanced and blueprinted motor should be better than factory in its clearances!

I'm tired of typing, so please, if anyone else can add of clean up my explanation-much appreciated for my learning progress!!!

Basically, any motor off the factory assembly line can be within a wide range of sloppy tolerances, meaning a motor can go out one day that has great fitment and tight clearances and the next day another assembly line motor can be at the high range of the allowed tolerances, resulting in a motor that is just a hair less productive in power and wear and tear than the next. You would probably never know that you had one of these "sloppy" motors unless you really pushed its limits (like forced induction on a naturally aspirated motor)...

now, back to rebuilding a motor and the importance of balancing and blueprinting...

balancing refers to making sure the rotating assembly-the crank, connecting rods, and the pistons are all within specs..

the rods need to be balanced to one another-meaning the weights will differ just a bit straight from production, so re-checking them and shaving off an extremely ammount of material on some of the heavier rods will help get them all to the same weight.

the pistons, the same...then figuring out the ratio of weight between the pistons and rods combined to the crank-0-for the vq, that number is 50%...

to finish the balancing process, the entire rotating assembly is turned on a jig-type of dealy and the crank is shaved down here and there (or even small amounts of metal added)-to ensure the smoothest rotating assembly possible

(BTW, if I left anything out or explained something weird, pls anyone, jump in and clarify...I am learning as well!)

Blueprinting refers to making sure evrything is fitted to extremely tight tolerances--meaning the main bearings are within xxx amount on each of the 4 crank journals (where the crank articulates w/ the block)...same with the rod bearings...torquing everything down to factory specification...basically a balanced and blueprinted motor should be better than factory in its clearances!

I'm tired of typing, so please, if anyone else can add of clean up my explanation-much appreciated for my learning progress!!!

#19

Registered User

Thread Starter

There is alot of great info in this thread and a MODERATOR should sticky this or pin it here in the FI section. HINT, HINT

This info will allow future FI owners to make better informed choices about going FI and building up their engines.

This info will allow future FI owners to make better informed choices about going FI and building up their engines.

#20

Registered User

Join Date: Jun 2003

Location: Charlotte, NC

Posts: 618

Likes: 0

Received 0 Likes

on

0 Posts

Originally posted by going deep

There is alot of great info in this thread and a MODERATOR should sticky this or pin it here in the FI section. HINT, HINT

This info will allow future FI owners to make better informed choices about going FI and building up their engines.

There is alot of great info in this thread and a MODERATOR should sticky this or pin it here in the FI section. HINT, HINT

This info will allow future FI owners to make better informed choices about going FI and building up their engines.