Twin Turbo Oil Pan Tap

#1

350Z-holic

Thread Starter

iTrader: (13)

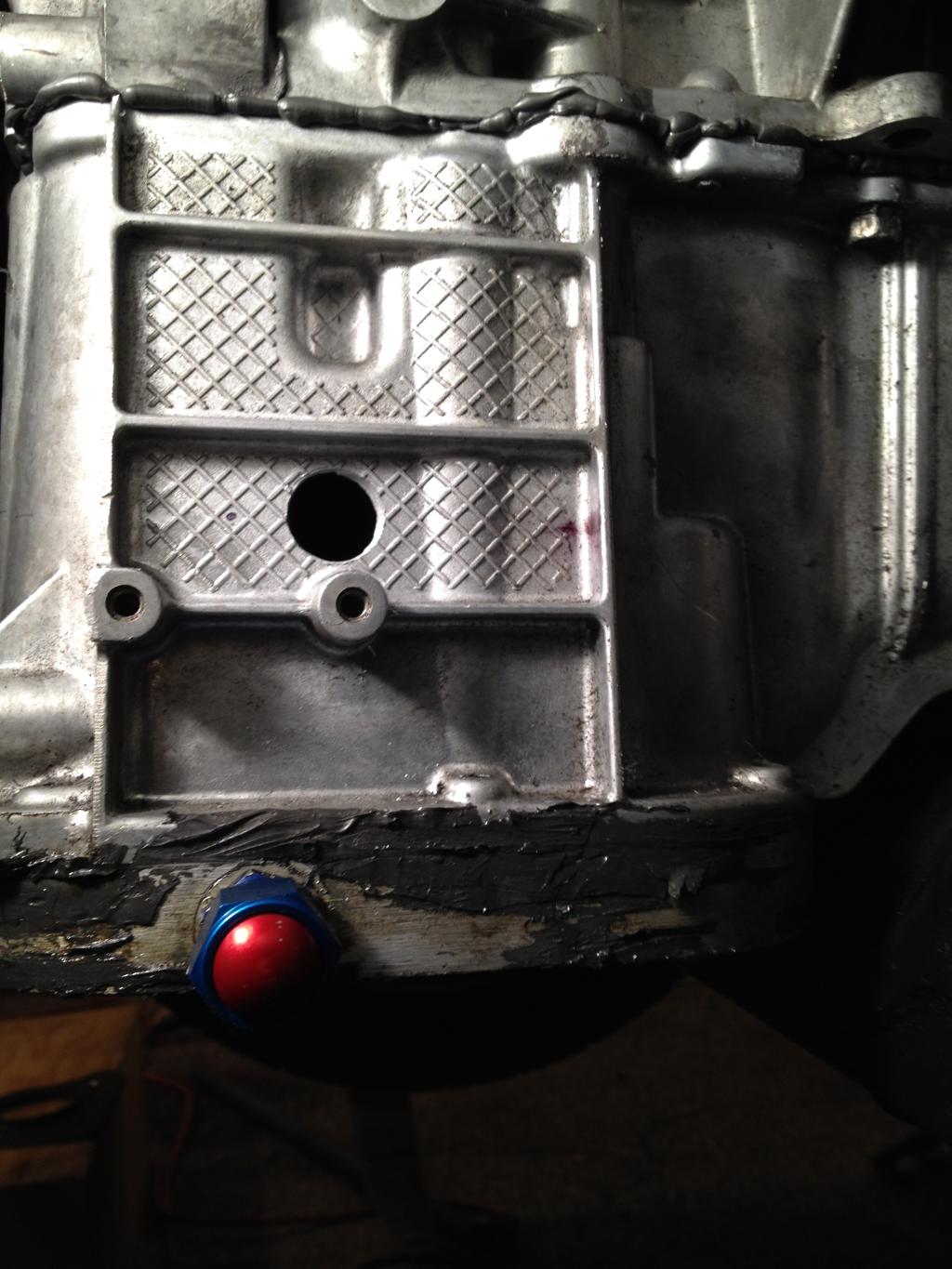

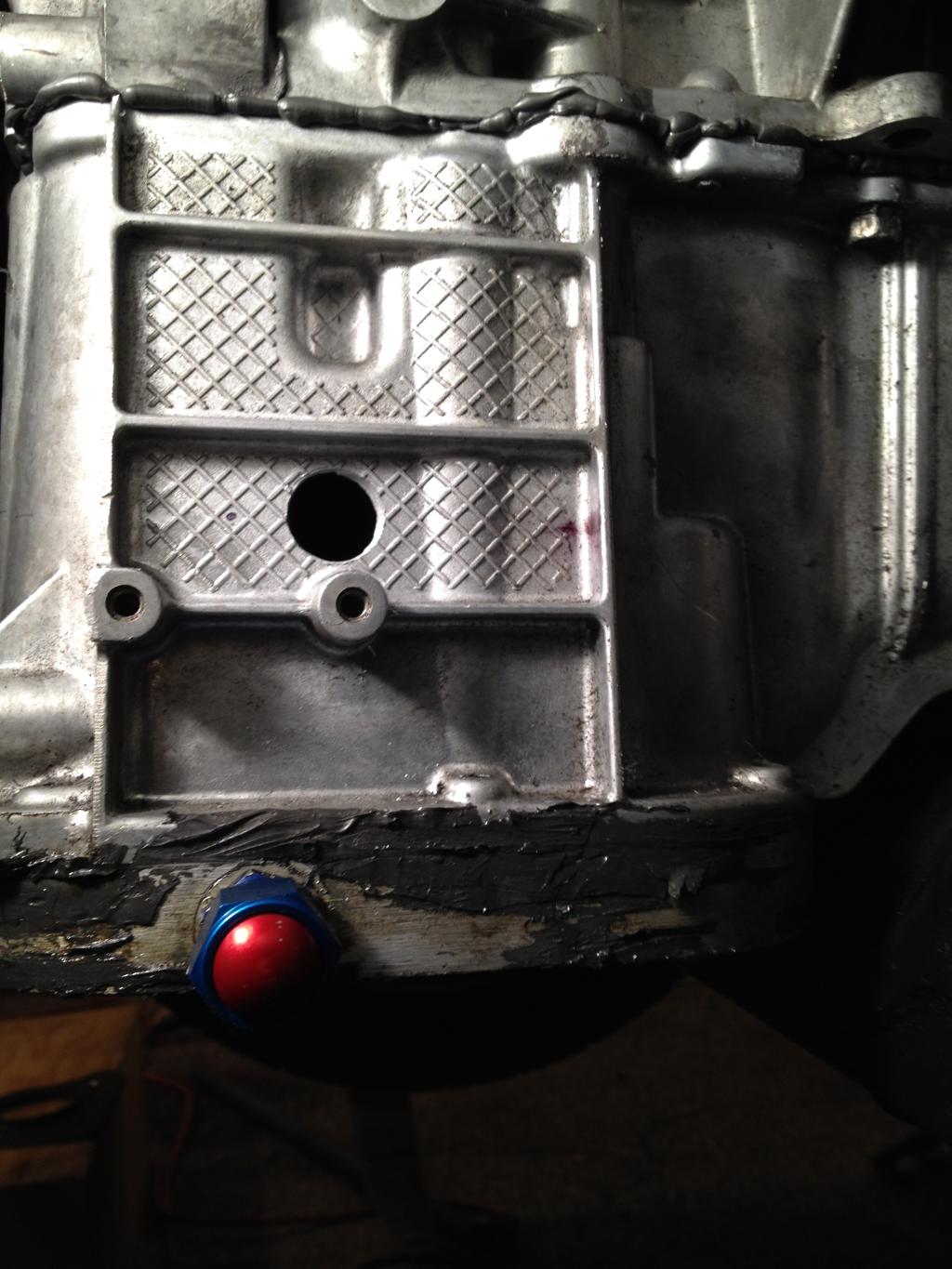

I dinged up my feed lines and decided I better change them out before resuming my build...along with the new lines I am going to re-route my scavenge lines from a oil pan spacer to upper oil pan tap.

After the considering the common methods (drill & tap threads, weld, bulkhead) I decided to go with a bolted bulkhead fitting. Drill & tap threads didnt make much sense seeing that the oil pan is so thin and welding is an option but pulling the block isnt something I want to do right now. A AN bulkhead fitting is a good option for where I'm at now. I intend to drill as small of a hole as needed, thread in washer on either side and bolt in place. I'll RTV the connection/void before I torque everything down. I believe I'm going to keep the oil pan spacer for the added oil capacity and cap the fittings.

I marked the 'high' oil level mark - which is about the bottom of the crank craddle and am trying to place the hole at that point - passenger side is clear but the driver side has structural moldings that will force it 1/2" lower - gonna try to make them at equal heights.

I have some new fittings coming next week -

After the considering the common methods (drill & tap threads, weld, bulkhead) I decided to go with a bolted bulkhead fitting. Drill & tap threads didnt make much sense seeing that the oil pan is so thin and welding is an option but pulling the block isnt something I want to do right now. A AN bulkhead fitting is a good option for where I'm at now. I intend to drill as small of a hole as needed, thread in washer on either side and bolt in place. I'll RTV the connection/void before I torque everything down. I believe I'm going to keep the oil pan spacer for the added oil capacity and cap the fittings.

I marked the 'high' oil level mark - which is about the bottom of the crank craddle and am trying to place the hole at that point - passenger side is clear but the driver side has structural moldings that will force it 1/2" lower - gonna try to make them at equal heights.

I have some new fittings coming next week -

Last edited by bealljk; 01-14-2015 at 08:41 PM.

#3

350Z-holic

Thread Starter

iTrader: (13)

Hardware came in today -

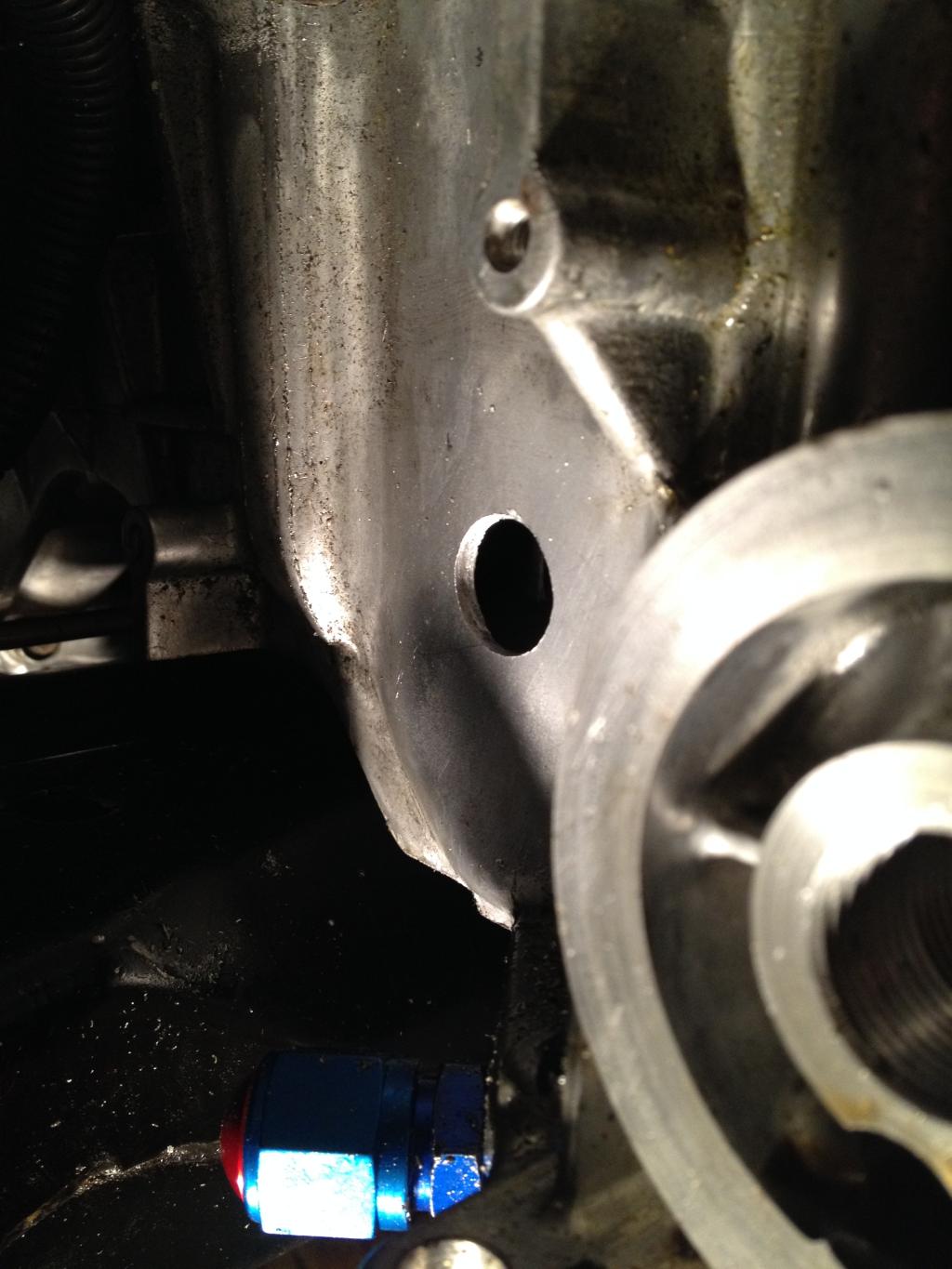

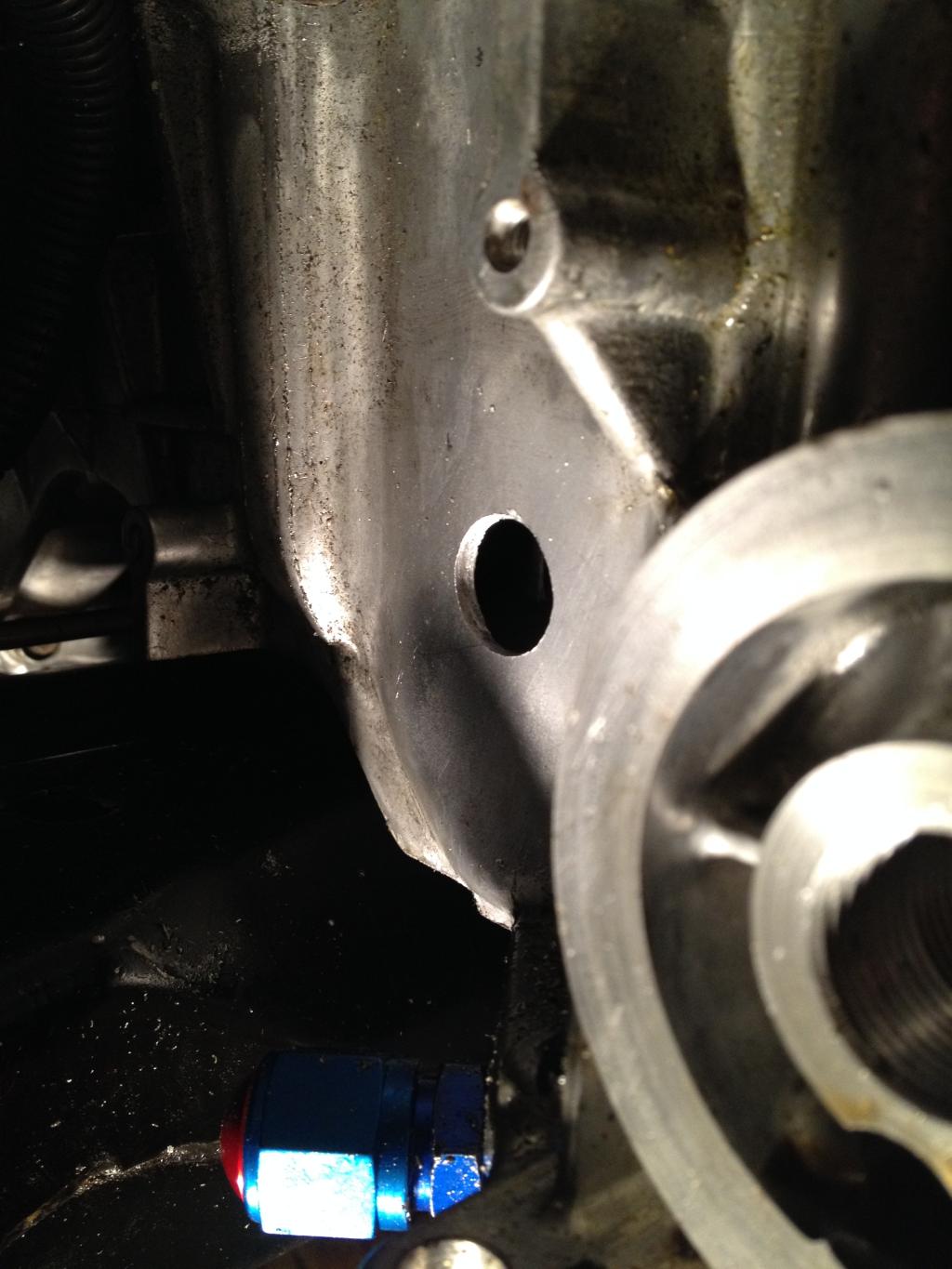

Driver side drilled - drilled a 1/8" pilot hole and used a 3/4" hole saw - used plenty of WD40 to clump shavings and lubricate the bit.

Dry run ... everything mated up as expected -

RTV'd

Passenger side:

Let the RTV sit for an hour or so to firm up before tightening up the first nut. Put ~ 40 ft*lbs on them and then added the second nut. I added a coating of lock-tite blue and put the same amount of torque on them.

Driver side drilled - drilled a 1/8" pilot hole and used a 3/4" hole saw - used plenty of WD40 to clump shavings and lubricate the bit.

Dry run ... everything mated up as expected -

RTV'd

Passenger side:

Let the RTV sit for an hour or so to firm up before tightening up the first nut. Put ~ 40 ft*lbs on them and then added the second nut. I added a coating of lock-tite blue and put the same amount of torque on them.

Last edited by bealljk; 01-16-2015 at 10:07 PM.

#6

Registered User

double nutting like that is actually counter-productive. The pressure the second nuts puts on the first nut takes the load off the threads of the first nut.

If you ever re-do it, flip the bulkhead fittings around so that the nut is on the outside of the engine. This way even if the nut comes loose, the bulkhead fitting could never fall in because it is still attached to the hose fitting.

If you ever re-do it, flip the bulkhead fittings around so that the nut is on the outside of the engine. This way even if the nut comes loose, the bulkhead fitting could never fall in because it is still attached to the hose fitting.

Trending Topics

#8

350Z-holic

Thread Starter

iTrader: (13)

double nutting like that is actually counter-productive. The pressure the second nuts puts on the first nut takes the load off the threads of the first nut.

If you ever re-do it, flip the bulkhead fittings around so that the nut is on the outside of the engine. This way even if the nut comes loose, the bulkhead fitting could never fall in because it is still attached to the hose fitting.

If you ever re-do it, flip the bulkhead fittings around so that the nut is on the outside of the engine. This way even if the nut comes loose, the bulkhead fitting could never fall in because it is still attached to the hose fitting.

Thread

Thread Starter

Forum

Replies

Last Post