DE Coolant Return, Through the Middle!

#1

Registered User

Thread Starter

I think a couple people have done this in the past?

We took a HR rear coolant outlet, and shortened both sides a little bit to make up for the shorter DE deck height. We made a billet part that is 2 pieces and passes through the timing chain in a circle to wide oval and back to circle transition.

A stock lower radiator hose made a perfect upper radiator hose with this layout.

Always HATED that ugly coolant return pipe on the side of the engine. This time around it had to go for sure anyway because the exhaust manifolds we made wouldnt fit with it there.

Thought some of you might find it cool!

We took a HR rear coolant outlet, and shortened both sides a little bit to make up for the shorter DE deck height. We made a billet part that is 2 pieces and passes through the timing chain in a circle to wide oval and back to circle transition.

A stock lower radiator hose made a perfect upper radiator hose with this layout.

Always HATED that ugly coolant return pipe on the side of the engine. This time around it had to go for sure anyway because the exhaust manifolds we made wouldnt fit with it there.

Thought some of you might find it cool!

The following users liked this post:

RaulAirZoom95 (06-06-2021)

#3

Registered User

Thread Starter

The factory oil cooler was eliminated almost 10 years ago on this particular 350z! In its place is a Mocal plate for a true oil cooler in the front end. The port on the thermo housing was tapped and plugged with a stainless Allen plug. The port on the previous coolant return pipe was cut off and welded shut. Also to note is that this car has had the radiator bypass eliminated a very long time ago. So the port for that on the HR coolant outlet was plugged and welded shut, and that pipe on the driver side coolant pipe was cut off and welded shut on the 2 bolt flange by the water pump. Throttle coolant also eliminated.

The only coolant hoses left are the 2 heater hoses and radiator hoses! Pretty much all the junk that doesn't matter was removed so that there is more room for the stuff that matters. It is still a street car... Only "street" thing removed that sucks to not have is the AC. It was taken out to put the power steering pump in its location, to give the passenger air intake pipe some room to be 3" and not crammed in.

The only coolant hoses left are the 2 heater hoses and radiator hoses! Pretty much all the junk that doesn't matter was removed so that there is more room for the stuff that matters. It is still a street car... Only "street" thing removed that sucks to not have is the AC. It was taken out to put the power steering pump in its location, to give the passenger air intake pipe some room to be 3" and not crammed in.

Last edited by phunk2; 07-26-2014 at 07:43 PM.

#4

YUUUPPP..both Get That Money (who later stole the entire setup off my car before shipping it to SFR) and SFR, have built a system for me...Tim at SFR eliminated as many leak points as possible, welding the joints as I don't want to be bothered with a leak.

It's supposed to make bleeding the air from the system eaaasssy, as well as cooling the heads before the block like the HR (only if you modify the block-have to grind 2 openings lower).

I agree..with a TT, there is tooo much stuff on the passenger side.

It's supposed to make bleeding the air from the system eaaasssy, as well as cooling the heads before the block like the HR (only if you modify the block-have to grind 2 openings lower).

I agree..with a TT, there is tooo much stuff on the passenger side.

#5

Registered User

Thread Starter

Nice looking good there. It's cool how you guys put the HR pressure cap there too. We left the stock radiator cap location. That obviously wouldn't have fit with our intake manifold.

#7

Registered User

Join Date: Mar 2007

Location: Fayetteville, Georgia

Posts: 168

Likes: 0

Received 0 Likes

on

0 Posts

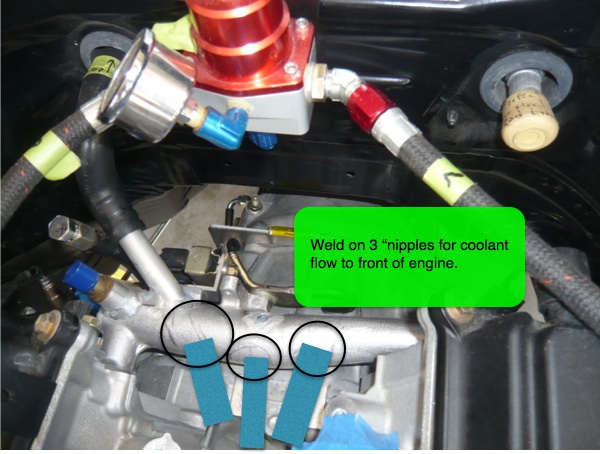

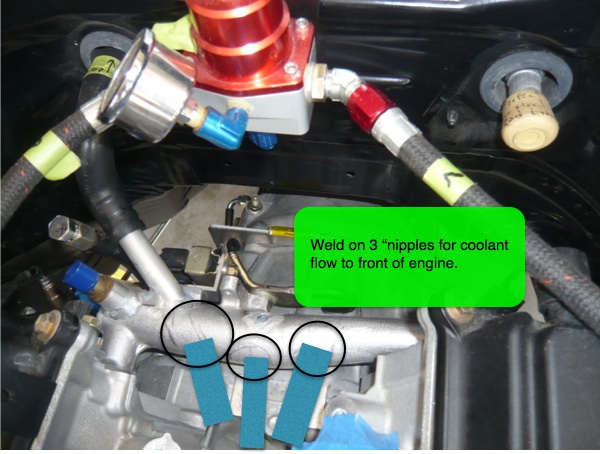

I am doing this on mine. The rectangular hole in the front presented a real problem so I went with 3 smaller hoses to get the flow volume necessary.

Its not pretty but I made filler in front like the HR to eliminate air problems.

I modified the rear cast piece and will fab up 3 outlets....kinda complex..

I will pick up the Pathfinder mod on the hose run forward.

Its not pretty but I made filler in front like the HR to eliminate air problems.

I modified the rear cast piece and will fab up 3 outlets....kinda complex..

I will pick up the Pathfinder mod on the hose run forward.

Trending Topics

#8

Registered User

iTrader: (4)

something i am really suprised no one has attempted to do yet is pull the impeller off the water pump and using it just as a idler. then reversing coolant flow, the outlets in the back of the head turn into inlets being fed by a external electric water pump from the radiator.

This would result in the area around the combustion chamber, the hottest part of the engine being cooled first and then traveling down the block and cooling the lower section, then it would flow into the water pump cavity and up to the thermostat location as the outlet. if the individual wanted to retain a thermostat a remote mount one could be placed between the radiator outlet and pump or outlet and radiator simply by flipping it. hoses for heater core could be routed to new locations so it remains functional without too much effort, and if wanting a clean look with less hoses a radiator with a top driver side inlet and bottom passanger side outlet so not stretching hoses in a criss cross in front of the engine.

would provide a better cooling setup and allow more power to be run possibly from cooling the chambers better through the coolant system for a even lower temp then normal when fuel enters and sucks heat out.

testing on other engine platforms like the lt1 have provided varying results on how much it actually helps in system temp but all agree it is at least a little bit lower operating temp(anywhere from 1 degree C to 5 degrees C) which makes me lead to believe if the entire system is cooler then there will be a much more significant change in the combustion chamber.

most OE's dont bother because of modern chamber designs, and the additional difficulty of trying to use such a cooling method with water pumps in the block but the lt1 can run a bit more compression and spark then a gen 1 small block with the same style heads which leads me to believe it works at least some as well. plus the engine would benefit from not driving the water pump anymore as well.

i know some domestic big block guys do it too, but havnt looked too much at their results.

This would result in the area around the combustion chamber, the hottest part of the engine being cooled first and then traveling down the block and cooling the lower section, then it would flow into the water pump cavity and up to the thermostat location as the outlet. if the individual wanted to retain a thermostat a remote mount one could be placed between the radiator outlet and pump or outlet and radiator simply by flipping it. hoses for heater core could be routed to new locations so it remains functional without too much effort, and if wanting a clean look with less hoses a radiator with a top driver side inlet and bottom passanger side outlet so not stretching hoses in a criss cross in front of the engine.

would provide a better cooling setup and allow more power to be run possibly from cooling the chambers better through the coolant system for a even lower temp then normal when fuel enters and sucks heat out.

testing on other engine platforms like the lt1 have provided varying results on how much it actually helps in system temp but all agree it is at least a little bit lower operating temp(anywhere from 1 degree C to 5 degrees C) which makes me lead to believe if the entire system is cooler then there will be a much more significant change in the combustion chamber.

most OE's dont bother because of modern chamber designs, and the additional difficulty of trying to use such a cooling method with water pumps in the block but the lt1 can run a bit more compression and spark then a gen 1 small block with the same style heads which leads me to believe it works at least some as well. plus the engine would benefit from not driving the water pump anymore as well.

i know some domestic big block guys do it too, but havnt looked too much at their results.

Last edited by jerryd87; 07-27-2014 at 07:41 PM.

#10

Registered User

iTrader: (4)

they actually didnt abandon it, GM has used reverse flow cooling since 55 in pontiacs. it is something they resort to when they are out of ideas to try and eek a bit more performance out of engines, then when something new is developed like new combustion chambers they go back to standard flow because its cheaper and easier to implement. plus reverse flow is finicky when bleeding.

the variable combustion ratio engines they are still developing supposedly use reverse flow.

like i said though some big block guys swear by it claiming more power from extra timing without detonation. its also really big in circle track.

it is something that is highly likely but impossible to prove one way or the other without testing both systems on the same engine. i do know from personal experience you can run more compression and timing on a lt1 reverse flow engine then a peanut head gen 1(same combustion chamber as the lt1) and standard cooling system, even with fuel injection like a holly stealth ram.

another thing with the reverse flow is that general motors was sued over the lt1 by evans cooling systems, the lt1 uses a unique reverse flow cooling system different from the earlier pontiac's that was developed by evans. evans sued because they never bought rights and GM won because he waited too long to file a patent on the design. i think he does now hold the patent for the system though.

edit:checked yah he officially holds a patent on the system now and i could be wrong but it looks like anyone who tries to use any sort of reverse flow in a commercial application would have to pay him.

the variable combustion ratio engines they are still developing supposedly use reverse flow.

like i said though some big block guys swear by it claiming more power from extra timing without detonation. its also really big in circle track.

it is something that is highly likely but impossible to prove one way or the other without testing both systems on the same engine. i do know from personal experience you can run more compression and timing on a lt1 reverse flow engine then a peanut head gen 1(same combustion chamber as the lt1) and standard cooling system, even with fuel injection like a holly stealth ram.

another thing with the reverse flow is that general motors was sued over the lt1 by evans cooling systems, the lt1 uses a unique reverse flow cooling system different from the earlier pontiac's that was developed by evans. evans sued because they never bought rights and GM won because he waited too long to file a patent on the design. i think he does now hold the patent for the system though.

edit:checked yah he officially holds a patent on the system now and i could be wrong but it looks like anyone who tries to use any sort of reverse flow in a commercial application would have to pay him.

Last edited by jerryd87; 07-29-2014 at 01:25 AM.

#11

Registered User

Thread Starter

There are ways around every patent... if Nissan, for example, wanted to cool the heads before the block or found a significant improvement in engine performance or efficiency that outweighed whatever negative... they would almost certainly do it. It doesnt cost anything extra if the engine is designed this way to begin with... then you dont have to "reverse" anything to accomplish the same task. You could just have the water pump, pump on into the heads with simple channeling in the rear timing case.

They spend millions and millions into developing a complex system like VVEL to bring small but measurable improvements in efficiency to their engine... surely they would have thought to run the coolant backwards if it was so beneficial?

They spend millions and millions into developing a complex system like VVEL to bring small but measurable improvements in efficiency to their engine... surely they would have thought to run the coolant backwards if it was so beneficial?

Last edited by phunk2; 07-29-2014 at 11:20 AM.

#12

New Member

iTrader: (1)

I would think that running the heads hotter would aid in fuel vaporization for better emissions. Not saying that was necessarily a consideration on the Z specifically, but possibly something that just carried over from other VQ applications.

This is a cool setup though. Very clean.

This is a cool setup though. Very clean.

#13

Registered User

iTrader: (4)

its not quite that simple, for a enthusiast yah sure it seems simple to reverse it because the time spent bleeding the system isnt a big deal. For a OEM however it is not,

1)the pumps themselves will be more expensive because impellers are unique.

2)flowing this way is much more prone to air pockets in the head which need to be solved as spending a large period of time to bleed the system costs the company money, both in repairs and assembly time. to put that time in perspective, at the plant i worked at the line being shut down for 1 minute cost $10,000 and it was a commercial plant. while bleeding wouldnt shut the line down it would slow it and that costs big money. it would be more feasible for the GTR.

bleeding the air like this is where evans came in with "vent holes", the way the patent is worded their is no getting around it. despite what some people say their isnt any "change one thing and your good" you have to change quite a bit. example? google and android phone makers have been sued by apple for "copying" ios in pretty much every country it has sold and has won in several of them.

3)a normal engine flows into the block and pressure bleeds off into the head. this means you only need one inlet into the engine, reverse it and you need to have multiple points flowing into the head first then bleed off into the block. this means if your designing the engine from scratch you need additional water passages, the overall engine will be larger and again cost more money.

what your forgetting is that not a single OEM manufacturer is thinking "lets build the baddest engine possible" they are weighing options for performance to cost and what the target market will be. they have to keep costs in a certain range to turn a profit.

vvel is a completely different creature, vvel was designed literally to not have any benefit for peak power. this is demonstrated by the fact that power per liter is almost identical between the two, 89.4 in the HR to 89.7 in the VHR, enough that its within dyno margin of error.

vvels purpose is driveability, emissions and power under the curve, which it does very well. driveability is better if the oils not over heating since the computer can adapt the intake tract as needed. the torque in the engine picks up much faster and holds steady much better then the previous engines. plus the emissions outside the "target rpm range" of the cams is actually lower, peak emissions are unchanged however from what a previous engine would produce at 330 whp, but the epa dosnt test that.

reverse flow cooling on the other hand is pretty much targeted at peak power and performance. if anything it will hurt emissions under the curve from too much cooling dropping exhaust temps to where the cats are no longer working. the exact opposite of what every OEM is trying to do right now as emissions testing become more and more strict.

1)the pumps themselves will be more expensive because impellers are unique.

2)flowing this way is much more prone to air pockets in the head which need to be solved as spending a large period of time to bleed the system costs the company money, both in repairs and assembly time. to put that time in perspective, at the plant i worked at the line being shut down for 1 minute cost $10,000 and it was a commercial plant. while bleeding wouldnt shut the line down it would slow it and that costs big money. it would be more feasible for the GTR.

bleeding the air like this is where evans came in with "vent holes", the way the patent is worded their is no getting around it. despite what some people say their isnt any "change one thing and your good" you have to change quite a bit. example? google and android phone makers have been sued by apple for "copying" ios in pretty much every country it has sold and has won in several of them.

3)a normal engine flows into the block and pressure bleeds off into the head. this means you only need one inlet into the engine, reverse it and you need to have multiple points flowing into the head first then bleed off into the block. this means if your designing the engine from scratch you need additional water passages, the overall engine will be larger and again cost more money.

what your forgetting is that not a single OEM manufacturer is thinking "lets build the baddest engine possible" they are weighing options for performance to cost and what the target market will be. they have to keep costs in a certain range to turn a profit.

vvel is a completely different creature, vvel was designed literally to not have any benefit for peak power. this is demonstrated by the fact that power per liter is almost identical between the two, 89.4 in the HR to 89.7 in the VHR, enough that its within dyno margin of error.

vvels purpose is driveability, emissions and power under the curve, which it does very well. driveability is better if the oils not over heating since the computer can adapt the intake tract as needed. the torque in the engine picks up much faster and holds steady much better then the previous engines. plus the emissions outside the "target rpm range" of the cams is actually lower, peak emissions are unchanged however from what a previous engine would produce at 330 whp, but the epa dosnt test that.

reverse flow cooling on the other hand is pretty much targeted at peak power and performance. if anything it will hurt emissions under the curve from too much cooling dropping exhaust temps to where the cats are no longer working. the exact opposite of what every OEM is trying to do right now as emissions testing become more and more strict.

There are ways around every patent... if Nissan, for example, wanted to cool the heads before the block or found a significant improvement in engine performance or efficiency that outweighed whatever negative... they would almost certainly do it. It doesnt cost anything extra if the engine is designed this way to begin with... then you dont have to "reverse" anything to accomplish the same task. You could just have the water pump, pump on into the heads with simple channeling in the rear timing case.

They spend millions and millions into developing a complex system like VVEL to bring small but measurable improvements in efficiency to their engine... surely they would have thought to run the coolant backwards if it was so beneficial?

They spend millions and millions into developing a complex system like VVEL to bring small but measurable improvements in efficiency to their engine... surely they would have thought to run the coolant backwards if it was so beneficial?

#14

Registered User

iTrader: (4)

it exactly does, the hotter the heads the hotter the exhaust and the better the cats work.

to add to my previous post something else thats different from the 90's and now.......... back in the 90's when they saw a increase in emissions they simply pumped additional air into the exhaust with air pumps, diluting the emissions gases so that tailpipe sensors read it lower but not actually decreasing the amount produced............ that absolutely wont fly anymore.

like i said i am not claiming it definitely works or definitely does not work, only that im suprised no one has done it. while no oem might currently be doing it, circle track racers are which are still running around 800 whp through generation 1 small blocks and subject the cars to more abuse then any car here, and i dont mean driving it hard i mean flat out abuse. plus some of the drag racers that swear by it.

to add to my previous post something else thats different from the 90's and now.......... back in the 90's when they saw a increase in emissions they simply pumped additional air into the exhaust with air pumps, diluting the emissions gases so that tailpipe sensors read it lower but not actually decreasing the amount produced............ that absolutely wont fly anymore.

like i said i am not claiming it definitely works or definitely does not work, only that im suprised no one has done it. while no oem might currently be doing it, circle track racers are which are still running around 800 whp through generation 1 small blocks and subject the cars to more abuse then any car here, and i dont mean driving it hard i mean flat out abuse. plus some of the drag racers that swear by it.

I would think that running the heads hotter would aid in fuel vaporization for better emissions. Not saying that was necessarily a consideration on the Z specifically, but possibly something that just carried over from other VQ applications.

This is a cool setup though. Very clean.

This is a cool setup though. Very clean.

Last edited by jerryd87; 07-29-2014 at 01:31 PM.

#15

Registered User

iTrader: (1)

I thought the extra oxygen pumped into the exhuast manifolds actually helped burn off the unburnt fuel to reduce hydrocarbons. My early 80's ford 460 (uncatted from the factory) has it and I'm pretty sure they started doing it in the 70's. You're saying all it does is fool testing?

Last edited by djamps; 07-29-2014 at 07:44 PM.

#16

Registered User

iTrader: (4)

from my experience when i worked in a emissions certified repair facility(ohio they had a list of shops that where certified by the epa and where instructed to go to if the vehicle failed) thats what they did. we had our own tester which also tested volume and while the air being pumped in increased the total volume of the exhaust the total amount of co2, NOX, and voc's remained relatively unchanged.

we passed a few vehicles with temporary air pumps hooked up to dump more in because our system enclosed the entire tail pipe and read total output, the echeck stations was just a probe that was stuck in the tail pipe and couldnt measure volume, only a instantaneous "picture" of what was passing by at that moment and averaged it across multiple data points over 30 seconds.

i also knew guys who run gutted cats and had electric pumps on switchs that led to them and dumped in for their race cars to pass.

we passed a few vehicles with temporary air pumps hooked up to dump more in because our system enclosed the entire tail pipe and read total output, the echeck stations was just a probe that was stuck in the tail pipe and couldnt measure volume, only a instantaneous "picture" of what was passing by at that moment and averaged it across multiple data points over 30 seconds.

i also knew guys who run gutted cats and had electric pumps on switchs that led to them and dumped in for their race cars to pass.

I thought the extra oxygen pumped into the exhuast manifolds actually helped burn off the unburnt fuel to reduce hydrocarbons. My early 80's ford 460 (uncatted from the factory) has it and I'm pretty sure they started doing it in the 70's. You're saying all it does is fool testing?

Last edited by jerryd87; 07-29-2014 at 09:28 PM.

#17

Registered User

Thread Starter

Sure there are points here and there are also countless counterpoints and we could go back and forth to no end. I personally am not sold on it. I still believe its lack of use by OEMs to be the strongest argument. I don't believe the complications you present to be as significant as you do. When one manufacturer catches on to something great and useful for their engines, it doesn't take very long at all for other manufactures to develop their interpretation of it. Maybe Evans has some old patent on bleeding channels from the 90s, but I highly doubt it was any leading edge technology and after all these years if anyone gave a crap they would have found a better way.

Thread

Thread Starter

Forum

Replies

Last Post

Colombo

Forced Induction

35

11-09-2020 10:27 AM