DIY – How to polish your plenum (many pics)

#1

I am not an expert or a pro, I am not telling you this is the way it is done or has to be done.

This is what I did and used to polish my plenum, I made this thread to help others.

If you know a better or faster way to do this by all means post how, we are all here just to help each other.

---

---

This job took me 25 hours over 4-5 days. If I had done it over 2 days and had a larger compressor I think I could have done it in much less time, around 16 hours possibly.

---

---

Before:

after:

----------

before:

after:

--------

before:

after:

This is what I did and used to polish my plenum, I made this thread to help others.

If you know a better or faster way to do this by all means post how, we are all here just to help each other.

---

---

This job took me 25 hours over 4-5 days. If I had done it over 2 days and had a larger compressor I think I could have done it in much less time, around 16 hours possibly.

---

---

Before:

after:

----------

before:

after:

--------

before:

after:

Last edited by XERMAN2001; 04-09-2010 at 10:28 AM.

#2

I have seen a few zeds online here with a polished oem upper plenum and liked it so I decided to do mine. Some have done them themselves others have paid around $300 to get them done professionally.

Here is some of the equipment I needed to complete this project

-Safety glasses

-respirator

-ear protection

-gloves

I bought an extra plenum to polish that way my car would still be drivable. What it looked like when I stared, rough and dirty.

---

---

---

After 4 hours of using an air grinder with a 40 grit flap disk and a Rotary tool with a grinding stone. (should have took less time but even with 2 compressors I still had to wait for them to keep up)

Here is some of the equipment I needed to complete this project

-Air grinder

-40 grit flap disk

-Rotary tool with and assortment of grinding stones

On a small part of the plenum you can see I did a few more steps to see some shine, (I wanted some motivation lol)

---

---

--

--

Here is some of the equipment I needed to complete this project

-Safety glasses

-respirator

-ear protection

-gloves

I bought an extra plenum to polish that way my car would still be drivable. What it looked like when I stared, rough and dirty.

---

---

---

After 4 hours of using an air grinder with a 40 grit flap disk and a Rotary tool with a grinding stone. (should have took less time but even with 2 compressors I still had to wait for them to keep up)

Here is some of the equipment I needed to complete this project

-Air grinder

-40 grit flap disk

-Rotary tool with and assortment of grinding stones

On a small part of the plenum you can see I did a few more steps to see some shine, (I wanted some motivation lol)

---

---

--

--

Last edited by XERMAN2001; 04-09-2010 at 10:19 AM.

#3

After another 4 hours of using an air grinder with a 80 grit flap disk and a Rotary tool with a grinding stone and 80 grit flap wheel. (should have took less time but even with 2 compressors I still had to wait for them to keep up)

Here is some of the equipment I needed to complete this project

-Air grinder

-80 grit flap disk

-Rotary tool with and assortment of grinding stones, sanding wheels and flap wheels.

On a small part of the plenum you can see I did a few more steps to see some shine, (I wanted some motivation lol)

Here is some of the equipment I needed to complete this project

-Air grinder

-80 grit flap disk

-Rotary tool with and assortment of grinding stones, sanding wheels and flap wheels.

On a small part of the plenum you can see I did a few more steps to see some shine, (I wanted some motivation lol)

#4

After another 6 hours of using an electric orbital sander with 80 grit sand paper, 120 grit sand paper and 220 grit sand paper. A Rotary tool with a 80 grit flap wheel and wire wheel. (should have took less time but even with 2 compressors I still had to wait for them to keep up)

Here is some of the equipment I needed to complete this project

-5 inch electric orbital sander

-80 grit sand paper

-120 grit sand paper

-220 grit sand paper

-Rotary tool with and assortment sanding wheels, flap wheels and wire wheels.

--

--

--

--

Here is some of the equipment I needed to complete this project

-5 inch electric orbital sander

-80 grit sand paper

-120 grit sand paper

-220 grit sand paper

-Rotary tool with and assortment sanding wheels, flap wheels and wire wheels.

--

--

--

--

#5

After another 3 hours of wet sanding by hand with 400 grit and 800 grit. A Rotary tool with a 80 grit flap wheel, wire wheel and sanding wheel.

Here is some of the equipment I needed to complete this project

-400 grit wet sand paper

-800 grit wet sand paper

-Rotary tool with and assortment sanding wheels, flap wheels and wire wheels.

Here is some of the equipment I needed to complete this project

-400 grit wet sand paper

-800 grit wet sand paper

-Rotary tool with and assortment sanding wheels, flap wheels and wire wheels.

#7

After another 2 hours of using an air die grinder with a felt/cloth wheel and a White compound/bar.

After another 2 hours of using an air die grinder with a felt/cloth wheel and a Red compound/bar.

After another 2 hours of using an air die grinder with a felt/cloth wheel and Metal polish

--- another 6 Hours total---

Here is some of the equipment I needed to complete this project

-Air grinder

-an assortment of felt/cloth wheels

-White compound/bar

-Red compound/bar

-Metal polish

--

--HERE ARE THE PICS AFTER 25 HOURS OF WORK---

After another 2 hours of using an air die grinder with a felt/cloth wheel and a Red compound/bar.

After another 2 hours of using an air die grinder with a felt/cloth wheel and Metal polish

--- another 6 Hours total---

Here is some of the equipment I needed to complete this project

-Air grinder

-an assortment of felt/cloth wheels

-White compound/bar

-Red compound/bar

-Metal polish

--

--HERE ARE THE PICS AFTER 25 HOURS OF WORK---

Trending Topics

#12

Registered User

iTrader: (23)

Looks good ! I just did one for a buddy but I dont have air tools  so i did it mostly by hand

so i did it mostly by hand  took me all winter!! I do more sanding with finer grits and less buffing (due to the lack of tools) I finish mine off with a big electric buffer

took me all winter!! I do more sanding with finer grits and less buffing (due to the lack of tools) I finish mine off with a big electric buffer  they are a ton of work but the finished product makes it well worth it IMO.

they are a ton of work but the finished product makes it well worth it IMO.

took me all winter!! I do more sanding with finer grits and less buffing (due to the lack of tools) I finish mine off with a big electric buffer

took me all winter!! I do more sanding with finer grits and less buffing (due to the lack of tools) I finish mine off with a big electric buffer  they are a ton of work but the finished product makes it well worth it IMO.

they are a ton of work but the finished product makes it well worth it IMO.

#13

Looks good ! I just did one for a buddy but I dont have air tools  so i did it mostly by hand

so i did it mostly by hand  took me all winter!! I do more sanding with finer grits and less buffing (due to the lack of tools) I finish mine off with a big electric buffer

took me all winter!! I do more sanding with finer grits and less buffing (due to the lack of tools) I finish mine off with a big electric buffer  they are a ton of work but the finished product makes it well worth it IMO.

they are a ton of work but the finished product makes it well worth it IMO.

took me all winter!! I do more sanding with finer grits and less buffing (due to the lack of tools) I finish mine off with a big electric buffer

took me all winter!! I do more sanding with finer grits and less buffing (due to the lack of tools) I finish mine off with a big electric buffer  they are a ton of work but the finished product makes it well worth it IMO.

they are a ton of work but the finished product makes it well worth it IMO.

#14

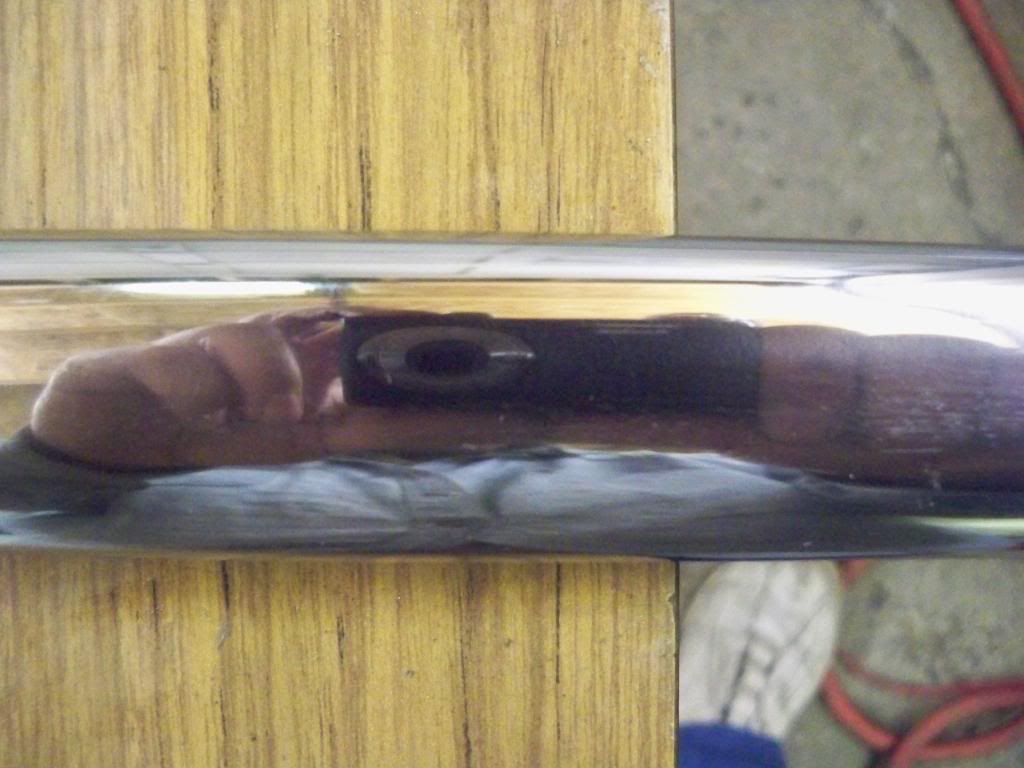

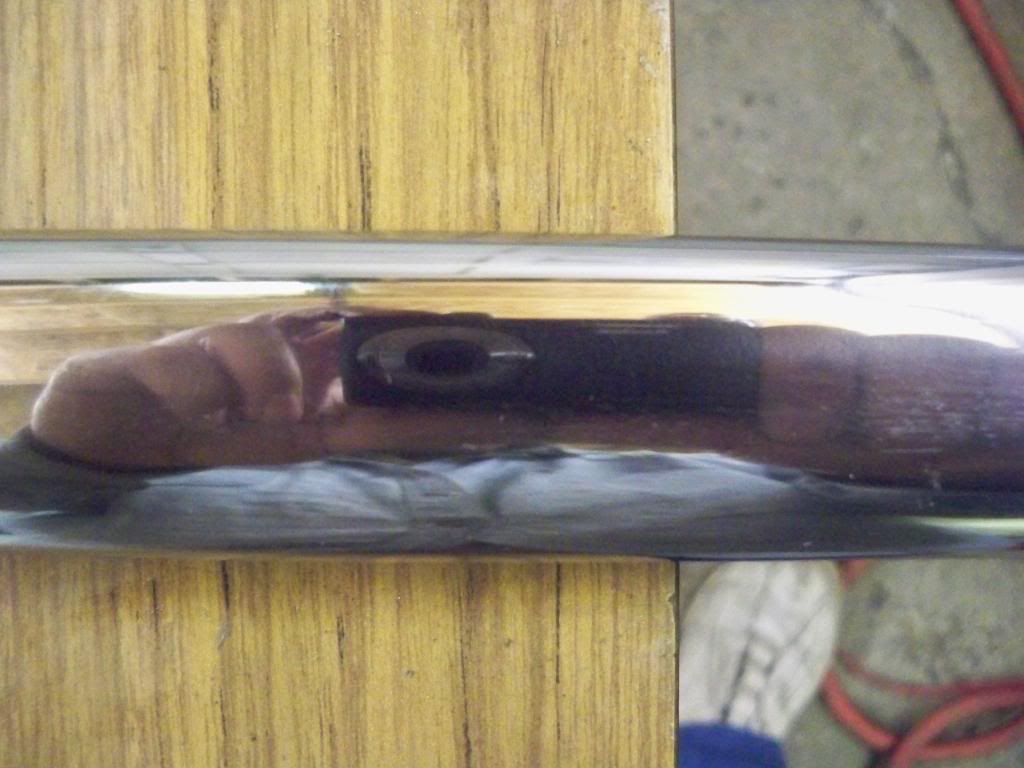

I also polished my strut bar. The bar is made of steel not aluminum so it can rust. The bar is not on the bar and was finished 4 weeks ago. It has been stored in the garage since then and shows no signs of rust. I am thinking/hoping that if I keep a protective coating of polish on the car it will not rust. If it does rust I will sand it again and clear coat it, or just reinstall my other oem bar.

Here is some of the equipment I needed to complete this project

-5 inch electric orbital sander

-Rotary tool with and assortment sanding wheels, flap wheels and wire wheels.

-Air grinder

-an assortment of felt/cloth wheels

-220 grit sand paper

-400 grit wet sand paper

-800 grit wet sand paper

-1000 grit wet sand paper

-black compound/bar

-Red compound/bar

-Metal polish

---------

i am not sure how long this took me, maybe 2-4 hours total.

before and after pics

Here is some of the equipment I needed to complete this project

-5 inch electric orbital sander

-Rotary tool with and assortment sanding wheels, flap wheels and wire wheels.

-Air grinder

-an assortment of felt/cloth wheels

-220 grit sand paper

-400 grit wet sand paper

-800 grit wet sand paper

-1000 grit wet sand paper

-black compound/bar

-Red compound/bar

-Metal polish

---------

i am not sure how long this took me, maybe 2-4 hours total.

before and after pics