Pulling Heads to Install L19ís and HKS Head Gaskets

#1

So, after lifting the heads several months ago (on ARP 2000 head studs and HR head gaskets), Iím finally getting ready to pull the heads off my engine to install the L19 head studs and HKS head gaskets.

Iím planning on removing the radiator support to access the engine/timing cover and pulling the heads with the engine in the car. Once the heads are off, Iíll check the block for straightness and take the heads to the machine shop to have them checked and resurfaced.

I was planning to install headers at the same time since theyíll have to be removed anyways. Only other thing Iíve been thinking about is if I should use copper spray on the head gaskets. An RB26 buddy recommends I use copper spray on my gaskets since I wonít be removing/machining the block. So, has anyone used copper spray on their HKS gaskets?

Iíll make sure to update this thread regularly.

Iím planning on removing the radiator support to access the engine/timing cover and pulling the heads with the engine in the car. Once the heads are off, Iíll check the block for straightness and take the heads to the machine shop to have them checked and resurfaced.

I was planning to install headers at the same time since theyíll have to be removed anyways. Only other thing Iíve been thinking about is if I should use copper spray on the head gaskets. An RB26 buddy recommends I use copper spray on my gaskets since I wonít be removing/machining the block. So, has anyone used copper spray on their HKS gaskets?

Iíll make sure to update this thread regularly.

Last edited by thatv35guy; 08-23-2018 at 09:03 AM.

#3

New Member

iTrader: (18)

Too nitty gritty detailed for me to answer, sorry man. Might want to call around to a few shops. I don't think most folks use a copper spray but then most would redeck the surface to ensure it is perfectly flat.

My 2 cents is to not use it unless an experienced vq35de engine builder weighs in...

My 2 cents is to not use it unless an experienced vq35de engine builder weighs in...

#5

350Z-holic

iTrader: (13)

I'd also pull the block - if you've gone as far to get the radiator mount off then it'll be worth it.

I sprayed my MLS OEM HR gaskets multiple times - spray them, let them sit for a few hours/overnight, spray them again, let them sit...(figuratively) rinse, lather, and repeat...and I'd have the heads machine no matter what...if youve spent $500 on studs, $200 on gaskets and the hours spent to get the work done, it'd be a shame to skip $100 on ensuring the heads are flat. I'd also consider replacing the water pump while your in the timing chain case.

Black RTV is your friend...

I sprayed my MLS OEM HR gaskets multiple times - spray them, let them sit for a few hours/overnight, spray them again, let them sit...(figuratively) rinse, lather, and repeat...and I'd have the heads machine no matter what...if youve spent $500 on studs, $200 on gaskets and the hours spent to get the work done, it'd be a shame to skip $100 on ensuring the heads are flat. I'd also consider replacing the water pump while your in the timing chain case.

Black RTV is your friend...

#6

I actually decided to attempt to pull the heads with the engine in after reading up on some of binder's posts: https://my350z.com/forum/forced-indu...ost-log-4.html We'll see once I actually strip the front end off though...

Yeah, the heads are going to the machine shop for sure. All together, I have just under 30k miles on this engine since it was built.

Yeah, the heads are going to the machine shop for sure. All together, I have just under 30k miles on this engine since it was built.

#7

So, we started pulling the heads on Friday, finished up Saturday night (thanks to wtfmike!). After we pulled the heads I boxed them and dropped them off at the machine shop on Monday (APD Power Center in Tempe), got a call the next day, they found detonation damage on the heads at the edge of the combustion chambers. The option is to have the heads welded and completely repaired (complete dis-assembly, valve job, etc.) or to finish resurfacing the heads and throw them back on.

Last edited by thatv35guy; 03-31-2016 at 09:18 AM.

Trending Topics

#9

New Member

iTrader: (18)

I am not sure the pitting will affect the headgasket seal at all. If those are stock heads might consider finding another donor. What cylinder is that? I would just machine flat and then focus on the cause of the detonation. Do you have a cosworth manifold? That sends more air to cylinders 5 and 6.

Last edited by rcdash; 03-31-2016 at 10:52 AM.

#10

That was the worst cylinder (not sure what cylinder number that was), but they all had some trace of pitting/detonation.

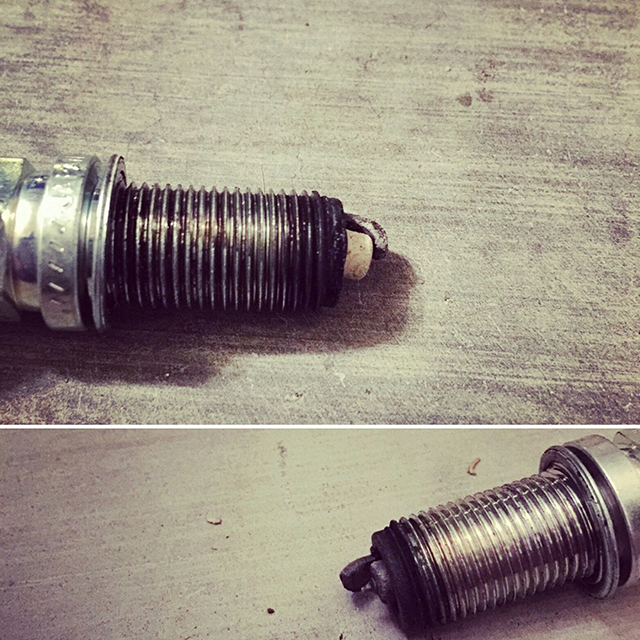

As far as the cause, my guess was that after I initially lifted the heads I stayed on the throttle for several consecutive pulls… and on the last pulls, that’s when I noticed detonation, I lost the plug ground and electrode on one or two cylinders then. That was roughly 5k miles ago.

As far as the cause, my guess was that after I initially lifted the heads I stayed on the throttle for several consecutive pulls… and on the last pulls, that’s when I noticed detonation, I lost the plug ground and electrode on one or two cylinders then. That was roughly 5k miles ago.

#11

Registered User

iTrader: (19)

if you lost parts of the plug in your engine, I would be concerned about that as well.... where they ended up and the damage they did along the way. If this were my engine,I would be looking very closely at the lower end and at the very least seeking out new heads to use.

#16

Registered User

make sure you have a second person holding the engine stand while you torque it from 60 ft lbs to 95 ft lbs.....lol

#17

Registered User

iTrader: (19)

all I know is, that you don't have an issue so visible in the heads without a problem some other place as well. I had a "headlift" incident myself last year.... 5 months and $9k later I think I have it resolved

#18

Registered User

9k

good god..... for me worst comes to worst i would take it to a DIY garage with 300 piece air tools and a lift and i would just sit there take it 1 bolt at a time and remove the entire subframe underneath........

good god..... for me worst comes to worst i would take it to a DIY garage with 300 piece air tools and a lift and i would just sit there take it 1 bolt at a time and remove the entire subframe underneath........

#19

Registered User

iTrader: (19)

this is me doing a fair amount of the work:

just some ballpark numbers for what I went through:

$1000 just into oem gaskets and parts - water pump, oil pump and rebuild gasket kit nearly gets you there alone!

4000-6000 for a short block depending on what you want in it. I bought a dynosty short block for this build -> CP 8.5:1, manley rods, billet girdle, and a couple other small upgrades. similar short block 5-7 yrs ago would be 1800 bucks cheaper

$1500 into a core long block, as my last one was unusable due to machine shop screw up

$1000-2000 to go through the heads (same job my good friend had done when we put his G35 together doubled in price in 7 yrs)... valve job, redeck, few hrs of some custom work

then there is the HKS gaskets, evans coolant, misc other parts, few gallons of oil and a few filters for motor break in.... then factor in $500-1500 for a retune.

OP might not be as bad off as I ended being, but I think he's looking at a little more than just cleaning up the heads and reinstalling