sintaxeror's build log - tons of PICS/No 56k!

#181

Administrator

iTrader: (25)

Keep the pics coming!

#182

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: St. Petersburg, FL

Posts: 670

Likes: 0

Received 0 Likes

on

0 Posts

UPDATE 3/18/08 Evening

Well despite what I said earlier I actually got a little done today on the enclosure..

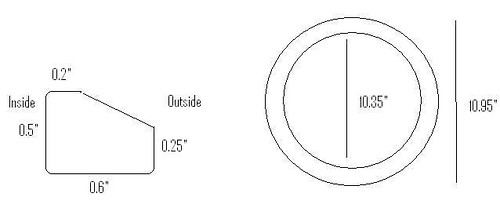

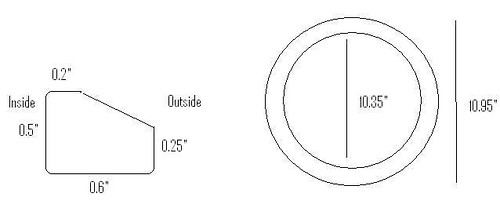

First order of business today was to figure out some kind of trim ring for the sub, since I am not flush mounting..

I don't have a router to make perfect rings, so I will actually have to farm this part of the project out...

Real designers don't need expensive engineering tools, real designers spec their parts out in MSPAINT.

eD, god bless their hearts, actually accepted this and agreed to make the ring for me.

This is what the foam looked like today, all cured.

And after a little carving..

and sanded flush..

Lets see how that curve cloth conforms to this box...

Another shot..

You know.. if the cloth will suffice the filling and sanding will be WAY easier... So I figured I'll give it a shot with one layer to try at first.. not to mention I can do the top and side all in one piece!

So lets give it a shot... I want the box to stay propped up without wobbling, so I added some weights to keep it still..

Weights went in through the terminal cutout.. Then I trimmed up some of the extra cloth.

Getting ready...

Covered in resin.. man that was way easier than chop mat. Just paint on and roll out the bubbles..

Shot of the other side...

So the idea is to see what its like cured.. and if it built some significant strength I will add a few more layers.. if not, I'll go back to the chop mat.

Should I go this route, I am going to have so much chop mat left over.. anyone in the tampa/st. pete area want to buy some cheap chop mat?

Another thought I had while doing this.. carbon fiber would be EASY and I would do that if I had anything else in carbon fiber in my car.. but I am not big on it like others are. So, what do you guys think?

Well despite what I said earlier I actually got a little done today on the enclosure..

First order of business today was to figure out some kind of trim ring for the sub, since I am not flush mounting..

I don't have a router to make perfect rings, so I will actually have to farm this part of the project out...

Real designers don't need expensive engineering tools, real designers spec their parts out in MSPAINT.

eD, god bless their hearts, actually accepted this and agreed to make the ring for me.

This is what the foam looked like today, all cured.

And after a little carving..

and sanded flush..

Lets see how that curve cloth conforms to this box...

Another shot..

You know.. if the cloth will suffice the filling and sanding will be WAY easier... So I figured I'll give it a shot with one layer to try at first.. not to mention I can do the top and side all in one piece!

So lets give it a shot... I want the box to stay propped up without wobbling, so I added some weights to keep it still..

Weights went in through the terminal cutout.. Then I trimmed up some of the extra cloth.

Getting ready...

Covered in resin.. man that was way easier than chop mat. Just paint on and roll out the bubbles..

Shot of the other side...

So the idea is to see what its like cured.. and if it built some significant strength I will add a few more layers.. if not, I'll go back to the chop mat.

Should I go this route, I am going to have so much chop mat left over.. anyone in the tampa/st. pete area want to buy some cheap chop mat?

Another thought I had while doing this.. carbon fiber would be EASY and I would do that if I had anything else in carbon fiber in my car.. but I am not big on it like others are. So, what do you guys think?

#185

Registered User

iTrader: (7)

Join Date: Aug 2006

Location: NJ

Posts: 2,136

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by sintaxeror

So the idea is to see what its like cured.. and if it built some significant strength I will add a few more layers.. if not, I'll go back to the chop mat.

Should I go this route, I am going to have so much chop mat left over.. anyone in the tampa/st. pete area want to buy some cheap chop mat?

Another thought I had while doing this.. carbon fiber would be EASY and I would do that if I had anything else in carbon fiber in my car.. but I am not big on it like others are. So, what do you guys think?

Should I go this route, I am going to have so much chop mat left over.. anyone in the tampa/st. pete area want to buy some cheap chop mat?

Another thought I had while doing this.. carbon fiber would be EASY and I would do that if I had anything else in carbon fiber in my car.. but I am not big on it like others are. So, what do you guys think?

As easy as it seems, carbon fiber cloth is not as easy to work with as fiberglass cloth. The weave can very easily get messed up and the final product will not look good. It's a good experience to try if you ever have the chance though.

#186

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: St. Petersburg, FL

Posts: 670

Likes: 0

Received 0 Likes

on

0 Posts

Disaster Strikes! eD accidentally sent me the wrong sub for replacement of the first 11o that I got. instead they sent me an 11k.. which I then used for mock up.

Cross your fingers that the 11o will fit (magnet is much bigger)... Hopefully they can get me an 11o quickly =/

Cross your fingers that the 11o will fit (magnet is much bigger)... Hopefully they can get me an 11o quickly =/

#187

Registered User

iTrader: (4)

Join Date: Mar 2006

Location: Lafayette LA

Posts: 3,804

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by sintaxeror

Disaster Strikes! eD accidentally sent me the wrong sub for replacement of the first 11o that I got. instead they sent me an 11k.. which I then used for mock up.

Cross your fingers that the 11o will fit (magnet is much bigger)... Hopefully they can get me an 11o quickly =/

Cross your fingers that the 11o will fit (magnet is much bigger)... Hopefully they can get me an 11o quickly =/

#189

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: St. Petersburg, FL

Posts: 670

Likes: 0

Received 0 Likes

on

0 Posts

So.. I cut out part of the hole in the sub and did some measuring.

I am 90% sure the 11o will not fit. =/

I am pretty upset... I guess I could just use the k, but I really wanted to use the o. I'm not sure the clearance is there to modify this box by just adding another ring on top and blending it.. I would have to change the mounting angle I think to fit the o... so I dont know. maybe have to start from scratch? Ugh. This is just bad luck.

Anyone have any ideas?

I am 90% sure the 11o will not fit. =/

I am pretty upset... I guess I could just use the k, but I really wanted to use the o. I'm not sure the clearance is there to modify this box by just adding another ring on top and blending it.. I would have to change the mounting angle I think to fit the o... so I dont know. maybe have to start from scratch? Ugh. This is just bad luck.

Anyone have any ideas?

#190

New Member

iTrader: (10)

You could probably recoup the cost of building from scratch by selling that box if there's no other way.

If the new sub doesn't fit... build another box. Reading your project log leads me to believe you're the type of person who wouldn't be happy for settling with something "almost as good".

Just have to say it again... amazing build.

If the new sub doesn't fit... build another box. Reading your project log leads me to believe you're the type of person who wouldn't be happy for settling with something "almost as good".

Just have to say it again... amazing build.

#191

Registered User

iTrader: (4)

Join Date: Mar 2006

Location: Lafayette LA

Posts: 3,804

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by sintaxeror

So.. I cut out part of the hole in the sub and did some measuring.

I am 90% sure the 11o will not fit. =/

I am pretty upset... I guess I could just use the k, but I really wanted to use the o. I'm not sure the clearance is there to modify this box by just adding another ring on top and blending it.. I would have to change the mounting angle I think to fit the o... so I dont know. maybe have to start from scratch? Ugh. This is just bad luck.

Anyone have any ideas?

I am 90% sure the 11o will not fit. =/

I am pretty upset... I guess I could just use the k, but I really wanted to use the o. I'm not sure the clearance is there to modify this box by just adding another ring on top and blending it.. I would have to change the mounting angle I think to fit the o... so I dont know. maybe have to start from scratch? Ugh. This is just bad luck.

Anyone have any ideas?

#193

Registered User

Join Date: Jul 2006

Location: Southampton

Posts: 46

Likes: 0

Received 0 Likes

on

0 Posts

Just realised your going for 10s - I went with 8s for the reason you are finding - hard to fit in decent 10s due to thier magnets etc.

More than likely I will be changing my setup this year for a nice SQ 10"

More than likely I will be changing my setup this year for a nice SQ 10"

#194

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: St. Petersburg, FL

Posts: 670

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by MDK

You could probably recoup the cost of building from scratch by selling that box if there's no other way.

If the new sub doesn't fit... build another box. Reading your project log leads me to believe you're the type of person who wouldn't be happy for settling with something "almost as good".

Just have to say it again... amazing build.

If the new sub doesn't fit... build another box. Reading your project log leads me to believe you're the type of person who wouldn't be happy for settling with something "almost as good".

Just have to say it again... amazing build.

Originally Posted by cbr900son

IMO ur putting alot of work in ur system dont compromise now. Use the o

Originally Posted by StreetOC192

Wait for the O to come in before you get too stressed out about it. It may fit as-is, or may just need some slight modding to fit.

Originally Posted by Rob_Quads

Just realised your going for 10s - I went with 8s for the reason you are finding - hard to fit in decent 10s due to thier magnets etc.

More than likely I will be changing my setup this year for a nice SQ 10"

More than likely I will be changing my setup this year for a nice SQ 10"

thanks for all the encouragement guys! Eventually I will get this thing right!

#195

Registered User

iTrader: (7)

Join Date: Aug 2006

Location: NJ

Posts: 2,136

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by sintaxeror

Well, the story is this.. I got an 11o, it was scuffed up so eD sent me a new sub with a shipping label to send back the old sub (great company!). Unfortunately, they sent me the k, which I unwittingly used to mock everything up... So I still have the original O.. I will talk to eD tonight to see if they will let me use it for mock up while waiting for a new one... That being said, I am 95% sure it will not fit as it, and I think the mounting angle will need to be changed rather than just adding an extra ring for space. =/ We'll find out for certain this evening.

#196

Administrator

iTrader: (25)

Man, that is alot of work! Keep up the good work...

#197

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: St. Petersburg, FL

Posts: 670

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by StreetOC192

Well I have an idea for you if you find the magnet hits the side of the enclosure. I'll keep my eye on here for status.

#198

Registered User

iTrader: (4)

Join Date: Mar 2006

Location: Lafayette LA

Posts: 3,804

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by sintaxeror

I was thinking if it hits the side just a little I can grind out some room and then add glass to the other side for strength... is that similar to what you were thinking? I hope its that simple, but I am pretty sure that I am going to need more clearance than that... We'll find out this evening!

#199

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: St. Petersburg, FL

Posts: 670

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by cbr900son

Im thinking u could make another ring but angle it so one side is maybe 1/2" and the other side is 1/4" not sure just a idea that poped in my head.

#200

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: St. Petersburg, FL

Posts: 670

Likes: 0

Received 0 Likes

on

0 Posts

UPDATE 3/19/08 Night

Well, I'm sure you all are anxious to see what happened today... so lets start from the beginning...

This morning as I was leaving for work, I found a note on my door. Management here at my complex is not happy with me working on my car in the parking lot, and fiberglassing on my front porch.

At this point in today's update, life has given me lemons and I have made lemonade.

I spoke with them this afternoon, and got them to allow me to rent one of the garages we have here for a month... Having to pay for this sucked, but its not all bad.. I should be able to get a lot more done now with a garage. Also I get my living room back, which is nice.

Here is my new workspace..

I cut out most of the hole with a sharp knife..

Then trimmed it flush with the dremel...

Moment of truth... here is the test fit..

As expected.. it doesn't fit =/ Here is another shot illustrating..

It doesn't look like much of a gap here... but its more than a half inch. Thats more than I am comfortable just adding a ring to and trying to mold it in... looks like I will have to do something more drastic.

I was able to rip off a lot of the cloth since I hadn't yet trimmed the excess off..

Took out some of the ring supports..

So, at this point it is important to note that once again, life has given me lemons.. although this time I have chosen to mutilate the lemons with a dremel and then beat the **** out of them with a hammer.

Cut the ring off..

Cut some more and knocked some off with a hammer...

Knocked the rest of the top off...

Sanded everything back down.. does this look familiar to anyone else?

Then gave it a quick wash to get all the dust off..

So tomorrow I go back to the foam... here we go again. Now I need to calm my nerves after wrecking a weeks worth of work...

Although.. watching my Gators in NIT doesn't do anything to make me any happier.

Here we go again.. hope you guys stay along for the ride!

Well, I'm sure you all are anxious to see what happened today... so lets start from the beginning...

This morning as I was leaving for work, I found a note on my door. Management here at my complex is not happy with me working on my car in the parking lot, and fiberglassing on my front porch.

At this point in today's update, life has given me lemons and I have made lemonade.

I spoke with them this afternoon, and got them to allow me to rent one of the garages we have here for a month... Having to pay for this sucked, but its not all bad.. I should be able to get a lot more done now with a garage. Also I get my living room back, which is nice.

Here is my new workspace..

I cut out most of the hole with a sharp knife..

Then trimmed it flush with the dremel...

Moment of truth... here is the test fit..

As expected.. it doesn't fit =/ Here is another shot illustrating..

It doesn't look like much of a gap here... but its more than a half inch. Thats more than I am comfortable just adding a ring to and trying to mold it in... looks like I will have to do something more drastic.

I was able to rip off a lot of the cloth since I hadn't yet trimmed the excess off..

Took out some of the ring supports..

So, at this point it is important to note that once again, life has given me lemons.. although this time I have chosen to mutilate the lemons with a dremel and then beat the **** out of them with a hammer.

Cut the ring off..

Cut some more and knocked some off with a hammer...

Knocked the rest of the top off...

Sanded everything back down.. does this look familiar to anyone else?

Then gave it a quick wash to get all the dust off..

So tomorrow I go back to the foam... here we go again. Now I need to calm my nerves after wrecking a weeks worth of work...

Although.. watching my Gators in NIT doesn't do anything to make me any happier.

Here we go again.. hope you guys stay along for the ride!