Oil cooler/warmer removal.............

#61

Registered User

iTrader: (54)

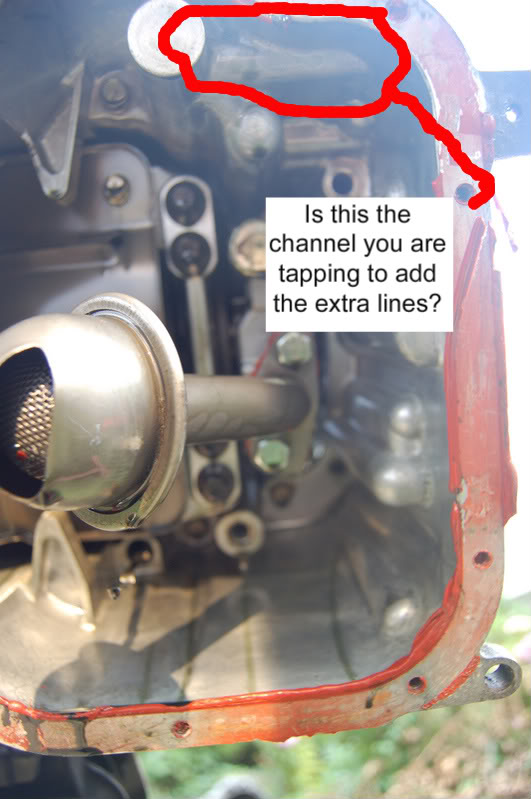

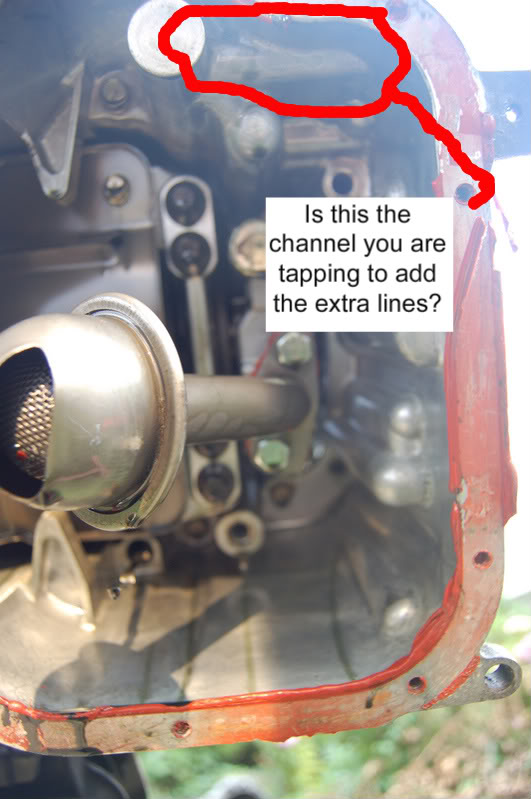

I found a picture I took doing my build which may demonstrate how I think you accomplished adding those lines..I am guessing that you do not drill all the way through, but just enough to get into the channel shown in the picture below. Charles, can you confirm that this channel will serve as a suitable oil pressure port?

Thanks.

Thanks.

#62

Originally Posted by rrmedicx

That is some really nice work Charles. I didn't know you could drill and tap the upper oil pan like that for an additional turbo feed line...or even from the side for the oil pressure sending unit. Any tricks to accomplishing this we little people should know???

Details...

Details...

#63

Registered User

Did you guys check the Manual Pathfinder`s Thermostat ? it comes with only one outlet the small one is disabled ? am not so sure but i`ll check it once i visit the dealer.

#64

rrmedix, I'll answer it for charles. yes that is the same oil gallery that feeds the oilpressure sending unit.

NetShark,

the pans have a second fitting that can be used for adapting external lines. It is above the oil filter location. on non-revups, nissan has a block-off fitting. On rev-ups, there is a sensor in that spot. I think it is used for oil temperature.

NetShark,

the pans have a second fitting that can be used for adapting external lines. It is above the oil filter location. on non-revups, nissan has a block-off fitting. On rev-ups, there is a sensor in that spot. I think it is used for oil temperature.

#65

CJ Motorsports

iTrader: (21)

actually its hard for me to tell from that picture especially since i did that over 2 years ago now... however, i trace oil passages around with compressed air usually, and just looking at the casting. the turbo oil feeds i did are pretty easy tho, as one of them is the stock oil pressure sensor location and then the one next to it i just tapped into the flat surface next to the stock pressure sensor location because i could tell it would go right into the same pressure channel.... and like quad is saying; the place i located the pressure sensor in the front is where there is normally some sort of ball bearing kind of plug to plug up the end of that channel that the turbo feeds are going into... it was a pain in the *** to get out.

Next time I am in there, I am going to use a 90 degree fitting to turn the pressure sensor... because right now its a little close to the greddy IC pipe for my liking.

Next time I am in there, I am going to use a 90 degree fitting to turn the pressure sensor... because right now its a little close to the greddy IC pipe for my liking.

#66

Registered User

Originally Posted by QuadCam

rrmedix, I'll answer it for charles. yes that is the same oil gallery that feeds the oilpressure sending unit.

NetShark,

the pans have a second fitting that can be used for adapting external lines. It is above the oil filter location. on non-revups, nissan has a block-off fitting. On rev-ups, there is a sensor in that spot. I think it is used for oil temperature.

NetShark,

the pans have a second fitting that can be used for adapting external lines. It is above the oil filter location. on non-revups, nissan has a block-off fitting. On rev-ups, there is a sensor in that spot. I think it is used for oil temperature.

#69

Originally Posted by rrmedicx

Thanks Quad & Charles for your response. Thinking about getting a 1/8 BSP tap to accomplish that project. Not 1/8 NPT?

#70

Charles,

Quick question for you. WHat size oil feed lines did you run to your greddys -3AN or -4AN? Also, what is the thread size for the oil feed side of the turbo. I want to replace the stock banjo fittings and oil feed lines. I plan to use standard An fittings, but I don't know the thread size for the banjo bolt. thanks.

Quick question for you. WHat size oil feed lines did you run to your greddys -3AN or -4AN? Also, what is the thread size for the oil feed side of the turbo. I want to replace the stock banjo fittings and oil feed lines. I plan to use standard An fittings, but I don't know the thread size for the banjo bolt. thanks.

Last edited by QuadCam; 06-26-2008 at 01:01 PM.

#72

I am having a ***** of a time trying to get that ball bearing out of the oil passage. I am worried that I may have f'ed the pan for trying to tap that for 1/8" BSP. I have a couple of extra pans, but this one I already had powder coated.

I have been using a taper-bit die grinder to go at that damn bearing. It is very time consuming!!!

I have been using a taper-bit die grinder to go at that damn bearing. It is very time consuming!!!

#73

Registered User

iTrader: (54)

Originally Posted by QuadCam

I am having a ***** of a time trying to get that ball bearing out of the oil passage. I am worried that I may have f'ed the pan for trying to tap that for 1/8" BSP. I have a couple of extra pans, but this one I already had powder coated.

I have been using a taper-bit die grinder to go at that damn bearing. It is very time consuming!!!

I have been using a taper-bit die grinder to go at that damn bearing. It is very time consuming!!!

Any pics of your efforts would be appreciated. I am pretty solid on what you are doing, but any visual aides would help.

Thanks Man. Keep up the good work.

#77

I was under my car over the weekend and was looking at the pan. It looks like if you relocate the OIL pressure sesnor to the front of the block, you are going to have to modify or remake the alternator bracket. ON phunk's car, it doesn't matter since he moved the accesories around anyway. On a stock car, the bracket appears to be in the way.

BTW, I got that damn ball bearing out! I had to show it who the BOSS is!!! I'll snap pics shortly.

I had to show it who the BOSS is!!! I'll snap pics shortly.

BTW, I got that damn ball bearing out!

#79

You'll laugh at the picture. The ball bearing has been mangled! It is so hard and so slippery that the die grinder bit kept slipping off of it and I hit the edge of thepan. the bit was chewing up the pan. once I got it out, I had to use a cut off wheel and a different die grinder bit to give the block a nice clean mating surface again around the new pressure port.

I have been thinking about leaving the oil pressure sensor in the stock loaction and just using a T-fitting in the new location to feed the turbos.

I have been thinking about leaving the oil pressure sensor in the stock loaction and just using a T-fitting in the new location to feed the turbos.

Last edited by QuadCam; 07-02-2008 at 07:35 AM.