why not increase boost to reduce trq drop

#61

Vendor - Former Vendor

iTrader: (7)

I have done this on several cars. It does work pretty well. Its hard to get a perfectly flat touque curve, becuase on alot of set ups you would probaly have to run up to 8-10lbs more boost to get it flat. Those are the cars that are probaly not built and not running turbo spec'd cams to help with the TQ curve drop.

Also, most people dont have a good enough boost controller that has duty cycle programable along with RPMS's(which is surprising with the amount of money people spend).

Also, most people dont have a good enough boost controller that has duty cycle programable along with RPMS's(which is surprising with the amount of money people spend).

#63

New Member

iTrader: (8)

Join Date: Jan 2007

Location: terre haute, IN; STL, MO

Posts: 6,457

Likes: 0

Received 7 Likes

on

6 Posts

It's F=MA not F=MV

If the rate of change of the rpms is the same from 3000rpm to 4000rpm as it is from 6000rpm to 7000rpm then the acceleration between those 2 is the same.

Acceleration is the RATE of change. meters per second per second. The rod velocity at 7k rpms is way higher, but it's not an equation of velocity, it's an equation of rate of change of velocity. On my timed logs the rate of change is nearly the same.

I guess it could apply to the pistons motion since they have to accelerate then negatively accelerate each cycle but to compare it to the rotational forces of the crank would be hard. I'll have to ask my dsm friend that is working on his physics phd to give me an explanation on it. He would probably be able to easily calculate it.

If the same tq at low rpm is the less dangerous then higher rpm then why are flat torque super chargers "safer" if they have nearly the same tq at redline? Shouldn't they be more dangerous since they carry the tq to redline?

#65

Registered User

iTrader: (2)

That actually makes my point.

It's F=MA not F=MV

If the rate of change of the rpms is the same from 3000rpm to 4000rpm as it is from 6000rpm to 7000rpm then the acceleration between those 2 is the same.

Acceleration is the RATE of change. meters per second squared(writing out per second per second puts the second second on top via PEMDOS ). The rod velocity at 7k rpms is way higher, but it's not an equation of velocity, it's an equation of rate of change of velocity. On my timed logs the rate of change is nearly the same.

). The rod velocity at 7k rpms is way higher, but it's not an equation of velocity, it's an equation of rate of change of velocity. On my timed logs the rate of change is nearly the same.

I guess it could apply to the pistons motion since they have to accelerate then negatively accelerate each cycle but to compare it to the rotational forces of the crank would be hard. I'll have to ask my dsm friend that is working on his physics phd to give me an explanation on it. He would probably be able to easily calculate it.

If the same tq at low rpm is the less dangerous then higher rpm then why are flat torque super chargers "safer" if they have nearly the same tq at redline? Shouldn't they be more dangerous since they carry the tq to redline?

It's F=MA not F=MV

If the rate of change of the rpms is the same from 3000rpm to 4000rpm as it is from 6000rpm to 7000rpm then the acceleration between those 2 is the same.

Acceleration is the RATE of change. meters per second squared(writing out per second per second puts the second second on top via PEMDOS

). The rod velocity at 7k rpms is way higher, but it's not an equation of velocity, it's an equation of rate of change of velocity. On my timed logs the rate of change is nearly the same.

). The rod velocity at 7k rpms is way higher, but it's not an equation of velocity, it's an equation of rate of change of velocity. On my timed logs the rate of change is nearly the same. I guess it could apply to the pistons motion since they have to accelerate then negatively accelerate each cycle but to compare it to the rotational forces of the crank would be hard. I'll have to ask my dsm friend that is working on his physics phd to give me an explanation on it. He would probably be able to easily calculate it.

If the same tq at low rpm is the less dangerous then higher rpm then why are flat torque super chargers "safer" if they have nearly the same tq at redline? Shouldn't they be more dangerous since they carry the tq to redline?

I agree with that though.

It's about the change in force. Yes a certain amount of torque will break a rod, but the speed at which the force is applied is just as important, if not more. The reasoning is physics (/endthread, jk).

How quickly an object changes force on a force vs time (or rpm graph) is the derivative of force. The derivative of force is directly related to the Jerk. Yes the Jerk. The Jerk is the derivative of acceleration or how quickly acceleration changes. F=m*a, and the derivative of force (again how quickly the force slope changes aka the slope of a torque reading on a dynograph) is dF=1/2a^2*da. The derivative of acceleration is a b*tch to find and therefore is called the jerk (CLICK AND READ http://en.wikipedia.org/wiki/Jerk_%2...thout_Calculus). So it can be difficult to put into lamens terms and grasp.

Basically when you put the same amount of force into something slowly, it can take the force better than if you put it in instantly.

In our car scenario, with rods, increasing torque when done slowly (think of rpm as time) that 'jerk' is lower. By increasing the peak rpm, you can more gradually reach the max force (or torque) via increments that are safe. 500ftlbs is 500ftlbs, whether its at 8,000rpm or at 2,000rpm.

You guys bring up a great point, that at 8,000rpm the rod is moving a lot more. That brings in a different part of the discussion, HP! hp=(torque*rpm)/5252. So by increasing the torque at the tail end of the dyno as str8 suggested a long time ago, you are forced to increase hp. The rod will likely take the force of the torque, but amount of work (in the same amount of time) will increase. That will cause something to fail. Most cases it's the rod bolts to go first with rpm. That simply has to do with the way rods are designed.

Rolling in the power can save rods, if you put in the same force of combustion later in the rpm band you'll make less torque, and that could save rods, but moving the same amount of torque further out won't save squat.

So yeah it goes into a bit deeper physics than I can explain (structural design and power vs torque/what components are effected by what), but I feel like that's a pretty good explanation for what's going on. It was fun coming up with this though!

#66

Registered User

iTrader: (4)

thats what i mean since there are more revolutions per minute then that means that each time the rod and piston accelerate, then stop, change direction and accelerate again all happens much quicker so the acceleration is much quicker since it is always either accelerating or decelerating.

most of the time the super chargers tend to fall off up top at least roots style do which is most of the ones i see with super flat torque curves, BUT if they do hold it all the way to redline i would have to say they are definatly more dangerous to the health of the engine. i havnt seen many turbos break high end cranks but i have seen cars with huge roots style break cranks at idle(we are talking like 2-4k callies pieces used in quad engine tractors for pulling.) after repeated beatings.

most of the time the super chargers tend to fall off up top at least roots style do which is most of the ones i see with super flat torque curves, BUT if they do hold it all the way to redline i would have to say they are definatly more dangerous to the health of the engine. i havnt seen many turbos break high end cranks but i have seen cars with huge roots style break cranks at idle(we are talking like 2-4k callies pieces used in quad engine tractors for pulling.) after repeated beatings.

That actually makes my point.

It's F=MA not F=MV

If the rate of change of the rpms is the same from 3000rpm to 4000rpm as it is from 6000rpm to 7000rpm then the acceleration between those 2 is the same.

Acceleration is the RATE of change. meters per second per second. The rod velocity at 7k rpms is way higher, but it's not an equation of velocity, it's an equation of rate of change of velocity. On my timed logs the rate of change is nearly the same.

I guess it could apply to the pistons motion since they have to accelerate then negatively accelerate each cycle but to compare it to the rotational forces of the crank would be hard. I'll have to ask my dsm friend that is working on his physics phd to give me an explanation on it. He would probably be able to easily calculate it.

If the same tq at low rpm is the less dangerous then higher rpm then why are flat torque super chargers "safer" if they have nearly the same tq at redline? Shouldn't they be more dangerous since they carry the tq to redline?

It's F=MA not F=MV

If the rate of change of the rpms is the same from 3000rpm to 4000rpm as it is from 6000rpm to 7000rpm then the acceleration between those 2 is the same.

Acceleration is the RATE of change. meters per second per second. The rod velocity at 7k rpms is way higher, but it's not an equation of velocity, it's an equation of rate of change of velocity. On my timed logs the rate of change is nearly the same.

I guess it could apply to the pistons motion since they have to accelerate then negatively accelerate each cycle but to compare it to the rotational forces of the crank would be hard. I'll have to ask my dsm friend that is working on his physics phd to give me an explanation on it. He would probably be able to easily calculate it.

If the same tq at low rpm is the less dangerous then higher rpm then why are flat torque super chargers "safer" if they have nearly the same tq at redline? Shouldn't they be more dangerous since they carry the tq to redline?

#67

New Member

iTrader: (8)

Join Date: Jan 2007

Location: terre haute, IN; STL, MO

Posts: 6,457

Likes: 0

Received 7 Likes

on

6 Posts

thats what i mean since there are more revolutions per minute then that means that each time the rod and piston accelerate, then stop, change direction and accelerate again all happens much quicker so the acceleration is much quicker since it is always either accelerating or decelerating.

resmarted, meter per second per second IS meter per second squared

#68

Registered User

iTrader: (4)

most times like resmarted said its rod bolts but sometimes when using really high end bolts like carrillo carr bolts it can be the rod. heard about it alot now only saw it personally once. picking up a engine at the machine shop kid dynoing his honda b18 i think it was, tuner told him not to take it higher then the 9k he was at but he was after some peak hp number and told the dyno operater to spin it to 10k. then i laughed as he cryed as he had a new window to check his oil level. scared the **** out of me at first since bottom half of it hit the wall with the window in it.

it get pretty rediculous when you combine the rpms some engine are turning and the power they are making, it not really one or the other its really the combination. ive seen eagle rods go in small block at 700 hp at only 6500 rpms.

it get pretty rediculous when you combine the rpms some engine are turning and the power they are making, it not really one or the other its really the combination. ive seen eagle rods go in small block at 700 hp at only 6500 rpms.

Last edited by jerryd87; 12-26-2011 at 12:54 PM.

#69

Registered User

iTrader: (2)

ya, i see the compression and tensile force increasing as the time is reduced for the accel and decel of the rod. The question is, is the compression and tensile forces on the rod what causes it to fail? i thought it was mostly shear forces that cause it to fail. I'm not a metallurgy though so i'm thinking of it as in respects to how human bone reacts to stress.

resmarted, meter per second per second IS meter per second squared i just lengthened it out so it made more sense when i was talking about the rate of change of velocity is the same thing as acceleration.

i just lengthened it out so it made more sense when i was talking about the rate of change of velocity is the same thing as acceleration.

resmarted, meter per second per second IS meter per second squared

#71

Registered User

Join Date: Jun 2011

Location: Portland, OR

Posts: 56

Likes: 0

Received 0 Likes

on

0 Posts

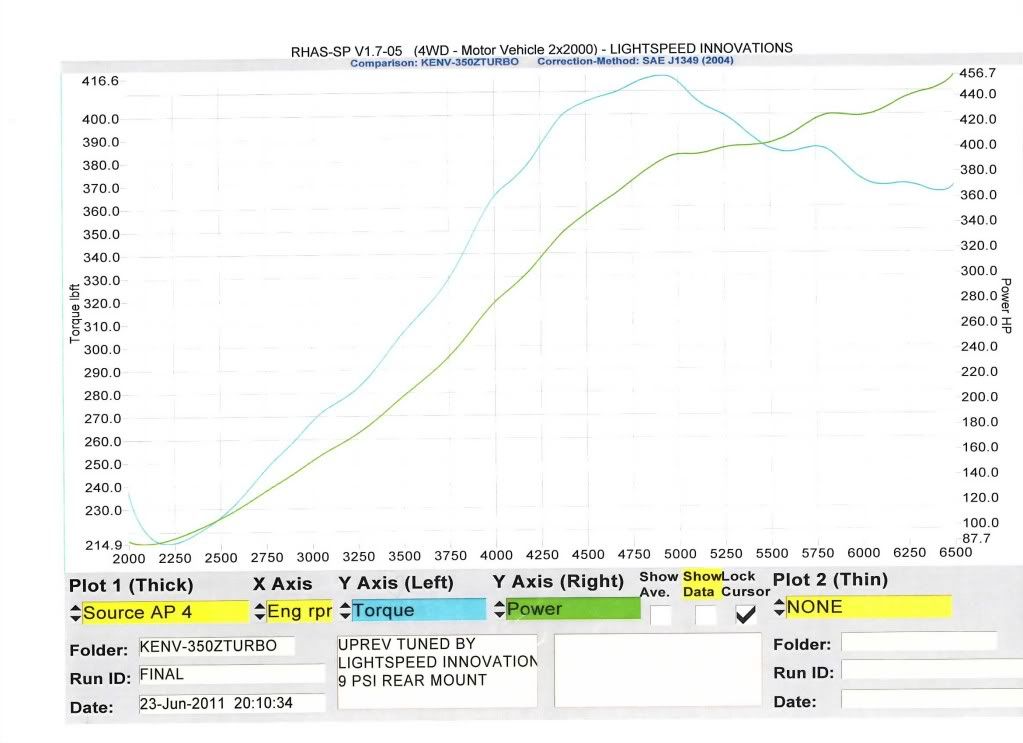

You can clearly see this is a dyno from an engine running out of turbo. You can not assume the turbo is not out of breath because it is. Adding a few pounds down low will definitely result in loss of tq and hp up top. This is probably true for most setups out there because people usually pick there turbo size as how much there engine can handle, not the other way around....

Last edited by Phamspeed; 12-27-2011 at 03:54 PM.

#72

Registered User

iTrader: (15)

Join Date: Sep 2007

Location: Staten Island,NY

Posts: 704

Likes: 0

Received 0 Likes

on

0 Posts

^ what are you talking about? That turbo is not out of efficiency, its making 450whp and 430 trq . Even if it was turboneticks 60-1 its good for 500whp

Look at my Dyno , I was using a holset hx40.

Look at my Dyno , I was using a holset hx40.

#73

Registered User

Join Date: Jun 2011

Location: Portland, OR

Posts: 56

Likes: 0

Received 0 Likes

on

0 Posts

Lets get down and dirty and see what really happens. Both graphs of the same car. You can see adding a few pounds at midrange effects the graph up high. Although this turbo is running out of steam, you can see how a spike of boost changes the whole curve..

#74

a GT3582 on a 3.5L is running out of steam at mid 400's??

I sure you hope you are not a tuner nor a shop with that much inexperience.

I sure you hope you are not a tuner nor a shop with that much inexperience.

You can clearly see this is a dyno from an engine running out of turbo. You can not assume the turbo is not out of breath because it is. Adding a few pounds down low will definitely result in loss of tq and hp up top. This is probably true for most setups out there because people usually pick there turbo size as how much there engine can handle, not the other way around....

Last edited by str8dum1; 12-27-2011 at 05:14 PM.

#76

Vendor - Former Vendor

iTrader: (14)

You can clearly see this is a dyno from an engine running out of turbo. You can not assume the turbo is not out of breath because it is. Adding a few pounds down low will definitely result in loss of tq and hp up top. This is probably true for most setups out there because people usually pick there turbo size as how much there engine can handle, not the other way around....

Clearly the turbo is not out of breath, considering that the 62mm billet wheel will flow over 73lbs/min of air.

Both the dyno you commented on and the graph above use the same Precision 6262 billet turbos, with T4 .58 a/r housings. If anyting the turbine housing will be the first thing to limit/taper power.

#77

New Member

iTrader: (8)

Join Date: Jan 2007

Location: terre haute, IN; STL, MO

Posts: 6,457

Likes: 0

Received 7 Likes

on

6 Posts

might have the car on the dyno either later this week or next week. I just hope i have enough time on this clutch. It has 1300 miles on previous owner and about 100 miles from me so it should be all set.

#78

New Member

iTrader: (8)

Join Date: Jan 2007

Location: terre haute, IN; STL, MO

Posts: 6,457

Likes: 0

Received 7 Likes

on

6 Posts

torque curve on a stock block ls1 with supercharger.

progressive torque until redline and the rods stayed in the car. This was last week at a local shop with one of the guys in our club.

Car pulls great. Doesn't have any drop off in the higher rpms. Just keeps pulling.

progressive torque until redline and the rods stayed in the car. This was last week at a local shop with one of the guys in our club.

Car pulls great. Doesn't have any drop off in the higher rpms. Just keeps pulling.

#79

Registered User

iTrader: (2)

Some guy locally (met him at the machine shop, who no longer has my block, Dynosty does

) picked up an lsx supercharged camaro for a couple of grand (it was a steal, the car has suspension work, full leather interior, very clean the s/c alone was worth what he paid). The car had a blown motor after like 70k miles on it, but put down nearly the same numbers when it was tuned (640rwhp I think).

) picked up an lsx supercharged camaro for a couple of grand (it was a steal, the car has suspension work, full leather interior, very clean the s/c alone was worth what he paid). The car had a blown motor after like 70k miles on it, but put down nearly the same numbers when it was tuned (640rwhp I think).

#80

New Member

iTrader: (8)

Join Date: Jan 2007

Location: terre haute, IN; STL, MO

Posts: 6,457

Likes: 0

Received 7 Likes

on

6 Posts

That's real nice.

Some guy locally (met him at the machine shop, who no longer has my block, Dynosty does ) picked up an lsx supercharged camaro for a couple of grand (it was a steal, the car has suspension work, full leather interior, very clean the s/c alone was worth what he paid). The car had a blown motor after like 70k miles on it, but put down nearly the same numbers when it was tuned (640rwhp I think).

) picked up an lsx supercharged camaro for a couple of grand (it was a steal, the car has suspension work, full leather interior, very clean the s/c alone was worth what he paid). The car had a blown motor after like 70k miles on it, but put down nearly the same numbers when it was tuned (640rwhp I think).

Some guy locally (met him at the machine shop, who no longer has my block, Dynosty does

) picked up an lsx supercharged camaro for a couple of grand (it was a steal, the car has suspension work, full leather interior, very clean the s/c alone was worth what he paid). The car had a blown motor after like 70k miles on it, but put down nearly the same numbers when it was tuned (640rwhp I think).

) picked up an lsx supercharged camaro for a couple of grand (it was a steal, the car has suspension work, full leather interior, very clean the s/c alone was worth what he paid). The car had a blown motor after like 70k miles on it, but put down nearly the same numbers when it was tuned (640rwhp I think).