HELP!!! Pilot bushing and pilot bearing problem.

#1

Registered User

Thread Starter

Join Date: Oct 2017

Location: california

Posts: 10

Likes: 0

Received 0 Likes

on

0 Posts

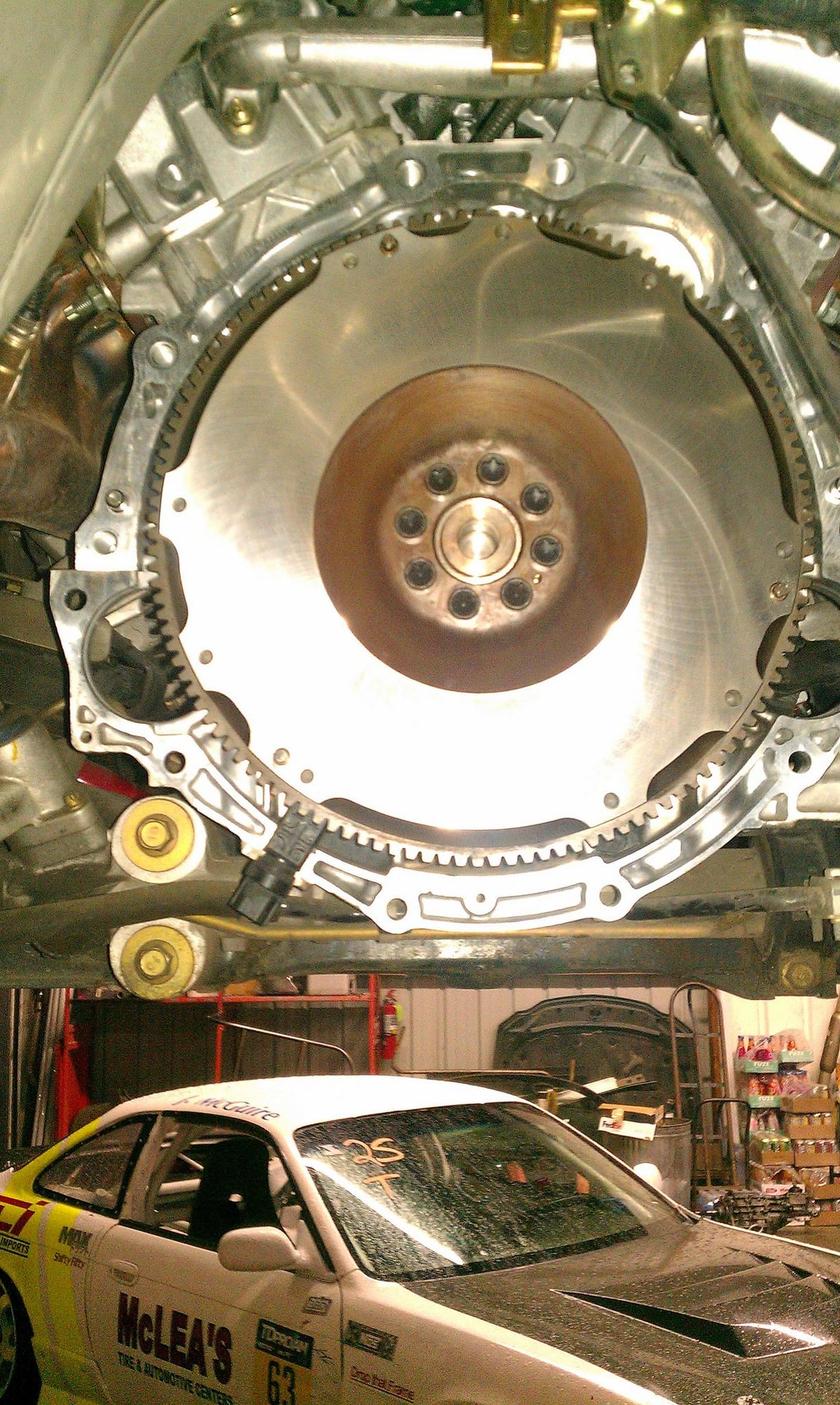

My 6spd 350z engine has a rod knock and i have a spare engine laying around but its was from an automatic so i got everything (plugs and hoses ) removed and swapped over. Thing i ran in to was a pilot bearing it seems like. I need to know if it is a bearing or its like that? And would i have to remove it or can i just mount on the flywheel? It seems a bit odd since what im looking at is a extra ledge coming from that hole compare to my original engine, it doesnt have that. maybe because it uses a pilot “bushing”. I tried the pilot bushing remover and hammer tool and the tool snap on me. So i went to go with a nut tighting puller tool but it seem like the two prones is to thick to catch any crest at the end of the bearing, and it just keep on slipping and scratching out. I even tried the bread trick. Worked for the bushing on my original engine but doest work on my the bearing on this automatic motor im about to drop in. So i started to think that piece doesnt come out at all. Can i be wrong? Has anyone ever swap in an automatic motor into there manual 350z? How’d you deal with this encounter? Please anyone????

#2

New Member

Alright man here's the deal. I've done this before. 6 speed swapped a G35.

Use some calipers to measure the inner diameter of the crankshaft, regardless if you think there is a bushing or not. If you think there is a bushing but you're not sure, there probably isn't because it would be brass/sintered bronze.

Compare your measurement to the outside diameter of the tranny input shaft.

ensure the input shaft is smaller.

Buy a bushing for a regular 350z

I found they were all too big on the outside.

Up to you where you go from there to fit the pilot bushing. I turned mine down using a dremel, letting it spin on the metal round I had for using the bread trick. Spinning it ensured I took off an even amount of material. Ish. It worked for 10k miles, crashed car so not sure past that.

Use some calipers to measure the inner diameter of the crankshaft, regardless if you think there is a bushing or not. If you think there is a bushing but you're not sure, there probably isn't because it would be brass/sintered bronze.

Compare your measurement to the outside diameter of the tranny input shaft.

ensure the input shaft is smaller.

Buy a bushing for a regular 350z

I found they were all too big on the outside.

Up to you where you go from there to fit the pilot bushing. I turned mine down using a dremel, letting it spin on the metal round I had for using the bread trick. Spinning it ensured I took off an even amount of material. Ish. It worked for 10k miles, crashed car so not sure past that.

Last edited by yosip1115; 10-15-2017 at 05:16 AM.

#4

New Member

Yeah. Make the bushing fit into the crank, you'll have to take some material off of the outside of it. Do it evenly. Make it so you tap it in semi gently, not so it's able to spin freely. Just want it to let the input shaft spin.

#5

Registered User

Thread Starter

Join Date: Oct 2017

Location: california

Posts: 10

Likes: 0

Received 0 Likes

on

0 Posts

thanks bud. So that little ledge so to speak Wouldnt cause any bolting back on problem?

#6

New Member

Looks like it is possible to remove that steel bushing in there comparing your pic to this one. If you can't get it out just do what I did. I didn't even try to get it out, thought it was solid steel.

#7

Trending Topics

#8

Registered User

Thread Starter

Join Date: Oct 2017

Location: california

Posts: 10

Likes: 0

Received 0 Likes

on

0 Posts

yeah! So auto is different from manual. But i just slap the two together. Make sure to put a new pilot bushing if your doing what i did. Taking a automatic engine and swap it to a manual. I just did that and worked out fine. Drove the car for a year and sold the car. Miss that car 😢

#9

So I get everything besides how far you push the bearing in??? Do I push it flush with the automatic thing or all the way in or like half way or like just past the ridge

#12

New Member

iTrader: (6)

Rent/buy a "Blind Hole Puller". Use it to remove the large auto bushing. Install manual pilot bushing. Done.

#13

Registered User

Join Date: Jul 2020

Location: Bowling Green, KY

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

I know this is a few months old, but this thread resonated enough with me to make an account and post that the bread method worked for me to remove the bearing. I soaked the auto bearing in pb blaster, the filled the hole with as much pb blaster as i could while simultaneously blocking it in with bread. The bread became damp and fluidic with compression, and the added bonus was that it was forcing the pbb behind the bushing. I used a perfectly sized socket and stuck a bolt into it to keep the bread from pushing out. Make it a long bolt, and really hammer on it good. It'll sound like metal on metal, but after feeling like I was going to run the bolt into the crank permanently, the thing just started coming out. Its a very heavy steel bushing. Also, if you get an aftermarket brass bearing, make sure you test your clutch alignment tool to make sure it isnt too tight. My aftermarket one that I pressed in was too tight for the transmission to fit.