Oil cooler/warmer removal.............

#1

Thread Starter

Registered User

iTrader: (8)

Joined: Apr 2003

Posts: 3,869

Likes: 4

From: Vero Beach, Florida

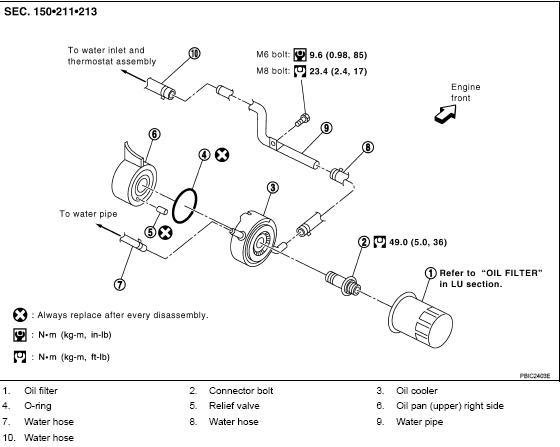

Here's a pic of the oil wamer/cooler from the service manual. I will be eliminating this deviceand it's associated plumbing from my engine. So, please don't debate over its usefulness or non-usefulness!

My question is what do I do with the stock "connector bolt" and also the "relief valve?"

Can the stock "connector bolt" be cut down and rethreaded? or does anyone know of a shorter bolt that fits these engines. I'm not even sure of the thread size. Unfortunately, I have 3 VQ35 engines and the only one with the bolt is the engine in my car.

I'd like to figure everything out before I tear it the project on my car.

I'd like to figure everything out before I tear it the project on my car.Secondly, what are the "relief valve?" Do I need to do anything with it? will it still work if I only have a filter screwed onto the block?

Thanks for any insight!!!

Andrew

#5

i just replace the entire thing with a MOCAL thermostatic oil cooler sandwich. In order to do so, we had to lathe a small sleeve to adapt the Mocal to mimick the cooler. Now my oil filter threads right onto the stock bolt and the mocal thing. its nice, got rid of the extra water lines for that thing too.

Trending Topics

#9

they are just bad news for highly modified cars. many engine builders will tell you to just replace that cooler every time you build your engine because it gets so clogged up with debris and they are impossible to totaly clean.

Advantages to removing it:

Cleans up engine bay a lot

Gives you a clean place to put an external cooler sandwich

no worries about it containing debris

disadvantages to removing it:

zero

My car warms up just a fast. My oil temps are only better with the front mounted cooler (which is behind my intercooler)

Advantages to removing it:

Cleans up engine bay a lot

Gives you a clean place to put an external cooler sandwich

no worries about it containing debris

disadvantages to removing it:

zero

My car warms up just a fast. My oil temps are only better with the front mounted cooler (which is behind my intercooler)

#10

Thread Starter

Registered User

iTrader: (8)

Joined: Apr 2003

Posts: 3,869

Likes: 4

From: Vero Beach, Florida

Originally Posted by Dave 90TT

I won't debate it with you, and won't counter your reason, but I am interested in your reason for removing it.

to get rid of crap on the car! I am also removing alot of the nipples on the water and heater pipes. There are so many small water hoses running all over the place. To me, those are just potential place for lines to burst and lines.

#11

Thread Starter

Registered User

iTrader: (8)

Joined: Apr 2003

Posts: 3,869

Likes: 4

From: Vero Beach, Florida

Originally Posted by phunk

i just replace the entire thing with a MOCAL thermostatic oil cooler sandwich. In order to do so, we had to lathe a small sleeve to adapt the Mocal to mimick the cooler. Now my oil filter threads right onto the stock bolt and the mocal thing. its nice, got rid of the extra water lines for that thing too.

Charles,

any pics of that sleeve you machined? any chance of machining another one?

Damn, I wish I had all the machine shop tools you have access to!

#12

Originally Posted by phunk

they are just bad news for highly modified cars. many engine builders will tell you to just replace that cooler every time you build your engine because it gets so clogged up with debris and they are impossible to totaly clean.

Advantages to removing it:

Cleans up engine bay a lot

Gives you a clean place to put an external cooler sandwich

no worries about it containing debris

disadvantages to removing it:

zero

My car warms up just a fast. My oil temps are only better with the front mounted cooler (which is behind my intercooler)

Advantages to removing it:

Cleans up engine bay a lot

Gives you a clean place to put an external cooler sandwich

no worries about it containing debris

disadvantages to removing it:

zero

My car warms up just a fast. My oil temps are only better with the front mounted cooler (which is behind my intercooler)

Ok, thanks for the reasons.

#13

Sorry for going slightly off topic, but since you're already doing it I thought I'd ask:

When I get my sandwich plate for my oil cooler, will it completely replace that "warmer/cooler" stuff you took out?

Hmmmmmm. . .so much to plan for! So much stuff to install! So little time!

When I get my sandwich plate for my oil cooler, will it completely replace that "warmer/cooler" stuff you took out?

Hmmmmmm. . .so much to plan for! So much stuff to install! So little time!

#14

Originally Posted by Drewer

When I get my sandwich plate for my oil cooler, will it completely replace that "warmer/cooler" stuff you took out?

You can also keep the warmer/cooler on. I have two sandwich plates (one Greddy for temp and pressure sensors, and one Mocal thermostat plate for my oil cooler), and the stock warmer/cooler. Clearance is a bit tight when changing the oil filter, but still possible.

#15

Originally Posted by Dave 90TT

It can.

You can also keep the warmer/cooler on. I have two sandwich plates (one Greddy for temp and pressure sensors, and one Mocal thermostat plate for my oil cooler), and the stock warmer/cooler. Clearance is a bit tight when changing the oil filter, but still possible.

You can also keep the warmer/cooler on. I have two sandwich plates (one Greddy for temp and pressure sensors, and one Mocal thermostat plate for my oil cooler), and the stock warmer/cooler. Clearance is a bit tight when changing the oil filter, but still possible.

LOL This one is a "outline" question:

I. For an oil pressure sensor, doesn't it need to be inline with the oil sender, ie with a pressure source?

......A. aka why use the second sandwich plate for the pressure?

...............1. also, can't you get the oil temp buy using a spacer?

Reason I ask is I plan on getting both sensors, but already have a tapped oil pan spacer which I plan to use for the temp sensor, but am still investigating where to run the pressure sensor from. Thanks!

Sorry for the threadjack, QuadCam!

#17

I just threaded the rest of the connector bolt and then cut it to size, removing the nut portion. Then I used an Earls sandwich adapter and used lock tite to link the connector bolt and the Earls bolt together making one long treaded piece with a sleeve in the middle to locate the sandwich plate...

Sorry no pictures, but it was pretty easy to do, had to special order a die that big to thread the bolt however...

Good Luck!

Sorry no pictures, but it was pretty easy to do, had to special order a die that big to thread the bolt however...

Good Luck!

#20

Thread Starter

Registered User

iTrader: (8)

Joined: Apr 2003

Posts: 3,869

Likes: 4

From: Vero Beach, Florida

I took my coolant and heater pipes to an experienced welder (17 yrs experience) to have him grind off and weld up the holes left by all the nipples I removed. I also had him weld up -8AN fittings for the radiator bypass hose.

The problem came from the heater and coolant pipes (the gold pipes on either side of the block). He's not sure what typeof alloy those pipes are made from, and whether he tried MIG or TIG welded on those pipes, there was some wierd off-gassing that was causing "porosity" in the welds.

Does anyone have any tips in regards to welding on those gold pipes? anyone know what nissan di to those pipes? I have heard of others having issues with welding on these pipes in the past, but I just assumed it was due to an inexperienced welder.

The problem came from the heater and coolant pipes (the gold pipes on either side of the block). He's not sure what typeof alloy those pipes are made from, and whether he tried MIG or TIG welded on those pipes, there was some wierd off-gassing that was causing "porosity" in the welds.

Does anyone have any tips in regards to welding on those gold pipes? anyone know what nissan di to those pipes? I have heard of others having issues with welding on these pipes in the past, but I just assumed it was due to an inexperienced welder.