rcdash v3.0 (by Dynosty)

#162

I did some research, and one guy on the forum had a problem with a wiring problem due to a Viper alarm system being wired to cylinder #1. I too have a Viper alarm system. I am going to look at how it is wired into my system. I had the same Viper alarm system back with my previous motor, and it did not create an issue. But time has passed. Insulation and connections may have degraded. I'll bet the issue is with the wiring. We will see.

#163

On another subject, we had a very difficult time with the closed loop boost control in the Haltech (Platinum Pro). I have the Haltech boost controller. We used the open loop base duty cycles, which were perfectly stable in open loop, decreased them by 5 points, and plugged them into the closed loop duty cycles. Even before playing with the PID values, leaving them set to 0, the boost was oscillating like crazy. Playing with the Proportional settings did no good. Nor did playing with the Integral settings. I had the control point offset set to 3 psi. Did you encounter this. Am I missing something?

Last edited by ttg35fort; 02-06-2015 at 06:58 PM.

#164

I'm tuning on 93 octane.

I did some research, and one guy on the forum had a problem with a wiring problem due to a Viper alarm system being wired to cylinder #1. I too have a Viper alarm system. I am going to look at how it is wired into my system. I had the same Viper alarm system back with my previous motor, and it did not create an issue. But time has passed. Insulation and connections may have degraded. I'll bet the issue is with the wiring. We will see.

I did some research, and one guy on the forum had a problem with a wiring problem due to a Viper alarm system being wired to cylinder #1. I too have a Viper alarm system. I am going to look at how it is wired into my system. I had the same Viper alarm system back with my previous motor, and it did not create an issue. But time has passed. Insulation and connections may have degraded. I'll bet the issue is with the wiring. We will see.

For the PID, set base duty cycle to about 70% what you had for open loop, set proportional to a low #, like 20, and I and D to 0. You should get undershoot with no oscillation. Work your way up on the integral slowly from there. You can use the derivative to reduce oscillations but I don't think I've ever needed it (always 0).

If boost is oscillating with everything set to 0, that means with no boost control (wastegate springs only) you have a problem. The solenoid will operate at boost duty cycle and not change. It should be the same as open loop. that does not make sense. Log actual solenoid duty cycle vs boost.

Last edited by rcdash; 02-06-2015 at 08:56 PM.

#165

Thanks for your help Raj. We put in 1 step colder NGK plugs gapped at 0.027" and new coils. Helped, but still some missing. We then changed the gap to 0.022". That in combination with the new coils worked, the missing up top went away.

Now for the downside, I have virtually the same build is Mike (XKR), same short block (except mine is flat decked), same cams, same intake, my heads are match ported, etc. The only real difference is that have GT3071 turbos instead of the GT35s, and I had the Greddy TT exhaust. Originally I had 0.064 A/R turbine housings, but torque was diving after 5k rpm. I changed the housings to 0.86 A/R (I had to have GT 28 housings custom machined because the 0.86 A/R GT30R housings are for a different trim) and changed out the Greddy TT to a full dual 3" dual exhaust. It helped, but my torque still is nose diving. I had 680 ft. lbs. of torque at 4200 rpm with 19 lbs of boost, but only hit about 610 hp at around 5k rpm.

We played with the boost vs rpm. I now have it set to go to 15 lbs at 4k rpm, then ramp up to 20 lbs at about 5200 rpm. My hp stays constant across the board at about 580 and does not gain. We can hear the motor struggling over 5k rpm. We played with the timing, cam phasing, and this helped a bit. But still, something is off.

We know the intake cams are working properly by monitoring them with the Haltech. I am wondering if the Exhaust cams are off by one tooth. Not sure. I think next we will be pulling the front off of the motor to check it. I can't think of anything else it could be. Any idea?

I would say it could be the GTM log style exhaust manifolds, but Mike made great hp with this turbo kit and motor. Also, my Greddy log style exhaust manifolds worked well on my first build.

Now for the downside, I have virtually the same build is Mike (XKR), same short block (except mine is flat decked), same cams, same intake, my heads are match ported, etc. The only real difference is that have GT3071 turbos instead of the GT35s, and I had the Greddy TT exhaust. Originally I had 0.064 A/R turbine housings, but torque was diving after 5k rpm. I changed the housings to 0.86 A/R (I had to have GT 28 housings custom machined because the 0.86 A/R GT30R housings are for a different trim) and changed out the Greddy TT to a full dual 3" dual exhaust. It helped, but my torque still is nose diving. I had 680 ft. lbs. of torque at 4200 rpm with 19 lbs of boost, but only hit about 610 hp at around 5k rpm.

We played with the boost vs rpm. I now have it set to go to 15 lbs at 4k rpm, then ramp up to 20 lbs at about 5200 rpm. My hp stays constant across the board at about 580 and does not gain. We can hear the motor struggling over 5k rpm. We played with the timing, cam phasing, and this helped a bit. But still, something is off.

We know the intake cams are working properly by monitoring them with the Haltech. I am wondering if the Exhaust cams are off by one tooth. Not sure. I think next we will be pulling the front off of the motor to check it. I can't think of anything else it could be. Any idea?

I would say it could be the GTM log style exhaust manifolds, but Mike made great hp with this turbo kit and motor. Also, my Greddy log style exhaust manifolds worked well on my first build.

Last edited by ttg35fort; 02-13-2015 at 05:32 AM.

#166

High rpm power is all about preventing air flow restriction. Can you identify all the piping sizes starting from the air filter and working your way back?

I have a GT28 turbine, you have a GT30. We both have housing A/R of 0.86. So turbos should not be the issue.

Let's ignore the GTM exhaust manifolds since you really cannot change that. One of the key points is the T25 flange vs the Tial v-band that I have (more like a T3). Anyway, moot point now.

You have a Cosworth, at least 2.25" intake piping, no exhaust restrictions (muffler, cats) etc?

I have a GT28 turbine, you have a GT30. We both have housing A/R of 0.86. So turbos should not be the issue.

Let's ignore the GTM exhaust manifolds since you really cannot change that. One of the key points is the T25 flange vs the Tial v-band that I have (more like a T3). Anyway, moot point now.

You have a Cosworth, at least 2.25" intake piping, no exhaust restrictions (muffler, cats) etc?

#167

I have a Cosworth plenum. I have a Magnaflow 3" ID resonator and small 3" ID muffler on the exhaust. Those are not very restrictive. The intake piping from the turbos to the intercooler is 2.25". The intake piping from the intercooler to the throttle body is 3".

Mike also had the same exhaust manifolds with T25 flanges. He posted a dyno plot way back with 850 whp, and said he eventually made 1000 whp, on Sharif's DD dyno, which is pretty conservative.

Mike also had the same exhaust manifolds with T25 flanges. He posted a dyno plot way back with 850 whp, and said he eventually made 1000 whp, on Sharif's DD dyno, which is pretty conservative.

#168

I have a Cosworth plenum. I have a Magnaflow 3" ID resonator and small 3" ID muffler on the exhaust. Those are not very restrictive. The intake piping from the turbos to the intercooler is 2.25". The intake piping from the intercooler to the throttle body is 3".

Mike also had the same exhaust manifolds with T25 flanges. He posted a dyno plot way back with 850 whp, and said he eventually made 1000 whp, on Sharif's DD dyno, which is pretty conservative.

Mike also had the same exhaust manifolds with T25 flanges. He posted a dyno plot way back with 850 whp, and said he eventually made 1000 whp, on Sharif's DD dyno, which is pretty conservative.

The easiest test to confirm no exhaust restriction is to just give it a shot on the dyno with just downpipes.

You are dropping your cam advance to zero towards high rpm?

Ignition advance increases towards high rpm?

Could be one turbo is not doing it's job and the other is overspinning. Do you have a way to measure at the compressor outlet of each? Measuring IAT may not work to identify this issue as your IC may compensate, especially in winter. Boost holding ok?

Last edited by rcdash; 02-13-2015 at 12:25 PM.

#169

Registered User

iTrader: (2)

I have a Cosworth plenum. I have a Magnaflow 3" ID resonator and small 3" ID muffler on the exhaust. Those are not very restrictive. The intake piping from the turbos to the intercooler is 2.25". The intake piping from the intercooler to the throttle body is 3".

Mike also had the same exhaust manifolds with T25 flanges. He posted a dyno plot way back with 850 whp, and said he eventually made 1000 whp, on Sharif's DD dyno, which is pretty conservative.

Mike also had the same exhaust manifolds with T25 flanges. He posted a dyno plot way back with 850 whp, and said he eventually made 1000 whp, on Sharif's DD dyno, which is pretty conservative.

Kind of sounds like an issue in the heads. Are you running dual AFR, or EGT or anything? Would be good to check if both heads are running the same temp wise. If one bank has mis-aligned exhaust cams you're going to see a difference.

A cam mis alignment might be the cause, might... One tooth off sure could be causing some weird things... I'd imagine an easy way to check for that is by doing a compression test. Doesn't sound like the low end power is hurt.

Which kind of leads me to think your 2.25" pipes might be a bit small?? I think 2.25 starts getting maxed a bit above 700cfm... 1400-1500cfm doesn't sound like it should make power just drop off lmao.

If you can get a laser/infrared thermometer to check the exhaust logs and the different ic piping during a pull that could help a lot.

Is the power always dropping off at the same rpm, even with the changes you made? Or is it boost dependent? Or...?

Last edited by Resmarted; 02-13-2015 at 06:42 PM.

#170

I logged the boost with the Haltech. It is holding solid.

To get to 700 whp, I calculate I would be pulling about 1120 cfm total, which is 560 cfm per side. 2.25" should be good for that.

Power is dropping off at the same rpm, regardless of boost.

My GT3071R turbos originally were 0.64 A/R with 84 trim. I changed the housings to 0.86 A/R (modified GT28 housings machined out to fit the turbine). The GT3071R turbos with 0.86 A/R normally have a 90 trim, which is a 56.5 mm inducer/53.6 mm exducer in comparison to my 56.5 mm inducer/51.8 mm exducer. So mine will be a little more restrictive than the factory 0.86 A/R setup, but I can't see that making a huge difference.

I have one O2 sensor in each downpipe for the Haltech, and another O2 sensor in the driver's side downpipe for my AFR gauge, but I don't see the O2 sensors creating too much restriction. I do have the wastegate exhaust going back into the downpipes, which the GTM downpipes are already configured to do.

We read my compression after about 1000 miles of break-in. My compression is really low, but pretty consistent across all 6 cylinders, even for 8.5:1 compression. 5 cylinders measure 125 dynamic compression and one measures 123. Since they were consistent, I had assumed the low dynamic compression was due to the intake/exhaust overlap at TDC. If the exhaust cam was off by one tooth, closing too late, this could account for the low compression and the torque drop at high rpm.

This week or next we are going to re-check the compression, and then again check it with a cap full of oil in at least one of the cylinders to see if it changes. If it changes, it could be a blow by problem. If it doesn't change, then it is not the rings.

To get to 700 whp, I calculate I would be pulling about 1120 cfm total, which is 560 cfm per side. 2.25" should be good for that.

Power is dropping off at the same rpm, regardless of boost.

My GT3071R turbos originally were 0.64 A/R with 84 trim. I changed the housings to 0.86 A/R (modified GT28 housings machined out to fit the turbine). The GT3071R turbos with 0.86 A/R normally have a 90 trim, which is a 56.5 mm inducer/53.6 mm exducer in comparison to my 56.5 mm inducer/51.8 mm exducer. So mine will be a little more restrictive than the factory 0.86 A/R setup, but I can't see that making a huge difference.

I have one O2 sensor in each downpipe for the Haltech, and another O2 sensor in the driver's side downpipe for my AFR gauge, but I don't see the O2 sensors creating too much restriction. I do have the wastegate exhaust going back into the downpipes, which the GTM downpipes are already configured to do.

We read my compression after about 1000 miles of break-in. My compression is really low, but pretty consistent across all 6 cylinders, even for 8.5:1 compression. 5 cylinders measure 125 dynamic compression and one measures 123. Since they were consistent, I had assumed the low dynamic compression was due to the intake/exhaust overlap at TDC. If the exhaust cam was off by one tooth, closing too late, this could account for the low compression and the torque drop at high rpm.

This week or next we are going to re-check the compression, and then again check it with a cap full of oil in at least one of the cylinders to see if it changes. If it changes, it could be a blow by problem. If it doesn't change, then it is not the rings.

Last edited by ttg35fort; 02-16-2015 at 07:16 AM.

#171

Registered User

iTrader: (2)

I logged the boost with the Haltech. It is holding solid.

To get to 700 whp, I calculate I would be pulling about 1120 cfm total, which is 560 cfm per side. 2.25" should be good for that.

Power is dropping off at the same rpm, regardless of boost.

My GT3071R turbos originally were 0.64 A/R with 84 trim. I changed the housings to 0.86 A/R (modified GT28 housings machined out to fit the turbine). The GT3071R turbos with 0.86 A/R normally have a 90 trim, which is a 56.5 mm inducer/53.6 mm exducer in comparison to my 56.5 mm inducer/51.8 mm exducer. So mine will be a little more restrictive than the factory 0.86 A/R setup, but I can't see that making a huge difference.

I have one O2 sensor in each downpipe for the Haltech, and another O2 sensor in the driver's side downpipe for my AFR gauge, but I don't see the O2 sensors creating too much restriction. I do have the wastegate exhaust going back into the downpipes, which the GTM downpipes are already configured to do.

We read my compression after about 1000 miles of break-in. My compression is really low, but pretty consistent across all 6 cylinders, even for 8.5:1 compression. 5 cylinders measure 125 dynamic compression and one measures 123. Since they were consistent, I had assumed the low dynamic compression was due to the intake/exhaust overlap at TDC. If the exhaust cam was off by one tooth, closing too late, this could account for the low compression and the torque drop at high rpm.

This week or next we are going to re-check the compression, and then again check it with a cap full of oil in at least one of the cylinders to see if it changes. If it changes, it could be a blow by problem. If it doesn't change, then it is not the rings.

To get to 700 whp, I calculate I would be pulling about 1120 cfm total, which is 560 cfm per side. 2.25" should be good for that.

Power is dropping off at the same rpm, regardless of boost.

My GT3071R turbos originally were 0.64 A/R with 84 trim. I changed the housings to 0.86 A/R (modified GT28 housings machined out to fit the turbine). The GT3071R turbos with 0.86 A/R normally have a 90 trim, which is a 56.5 mm inducer/53.6 mm exducer in comparison to my 56.5 mm inducer/51.8 mm exducer. So mine will be a little more restrictive than the factory 0.86 A/R setup, but I can't see that making a huge difference.

I have one O2 sensor in each downpipe for the Haltech, and another O2 sensor in the driver's side downpipe for my AFR gauge, but I don't see the O2 sensors creating too much restriction. I do have the wastegate exhaust going back into the downpipes, which the GTM downpipes are already configured to do.

We read my compression after about 1000 miles of break-in. My compression is really low, but pretty consistent across all 6 cylinders, even for 8.5:1 compression. 5 cylinders measure 125 dynamic compression and one measures 123. Since they were consistent, I had assumed the low dynamic compression was due to the intake/exhaust overlap at TDC. If the exhaust cam was off by one tooth, closing too late, this could account for the low compression and the torque drop at high rpm.

This week or next we are going to re-check the compression, and then again check it with a cap full of oil in at least one of the cylinders to see if it changes. If it changes, it could be a blow by problem. If it doesn't change, then it is not the rings.

And again, I said the afr thing not for restriction, but to compare how the two banks are working...

Does the car drop off power in the same way each time or?

Have you tried warmer plugs?

#172

The results are consistent. Also, AFR is consistent on both banks.

We started with 3 step colder plugs the previous week, but were getting some missing in the high rpms. 1 step colder plugs with a 0.022" gap and new coils fixed that issue. The missing is gone.

I was wondering if both exhaust cams were off one tooth, closing a little too late. It's highly unlikely both exhaust cams are off by one tooth while the intake cams are correct (we have verified the intake cams are correct by monitoring them with the Haltech data logging). But I was trying to think about what would give me (1) relatively low compression, (2) monster torque around 4k rpm and (3) drop in torque in high rpms. It seems like late opening/closing exhaust cams would do that, but I am merely speculating. The cam phasing probably is OK.

Next, we may hook up a pressure sensor to the exhaust side to see what kind of back pressure I am getting. It could be that reversion is the issue. XKR has the same turbo kit, but with GT35 turbos, and his torque holds strong. It could be the GT30 turbines are a little too small for my 4.0L motor. I'm not sure.

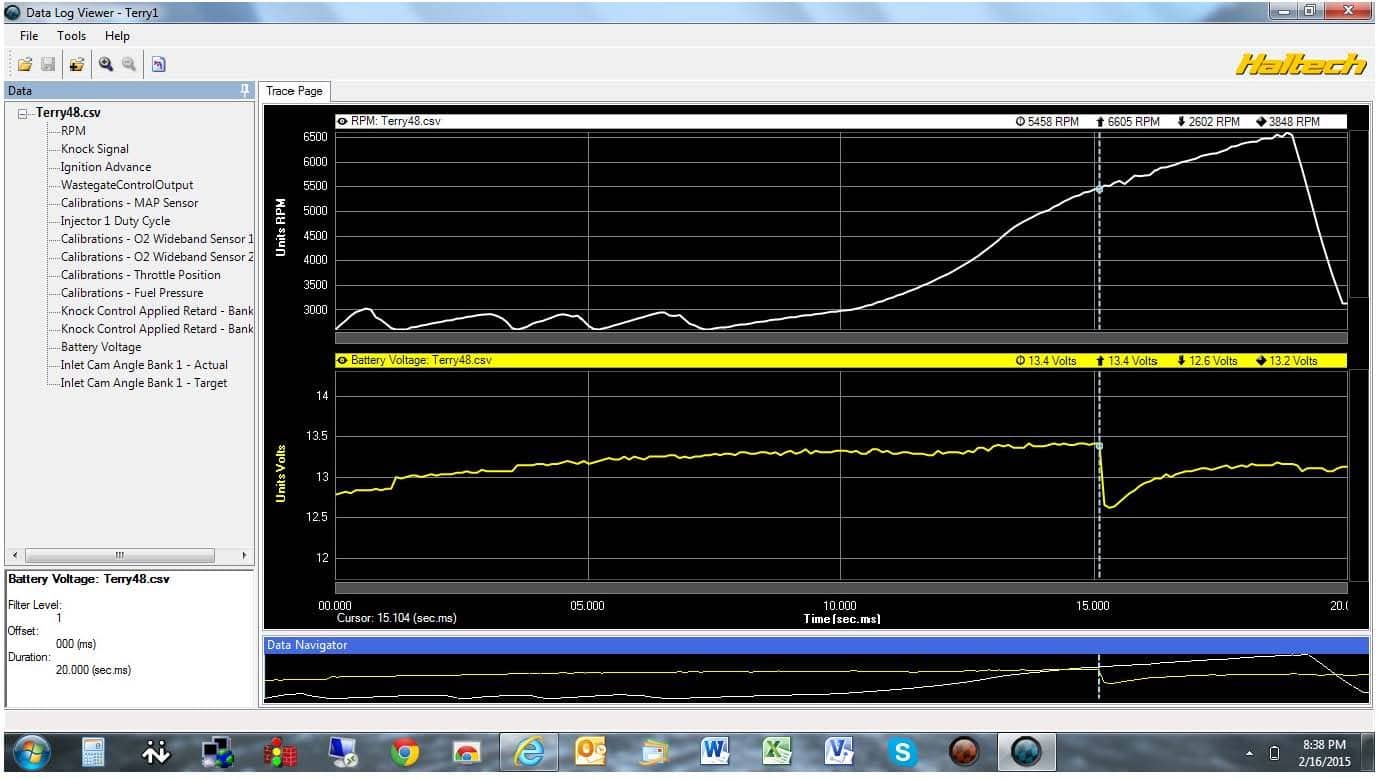

UPDATE: I just went through my logs from when I was on the dyno. It looks like my alternator is not keeping up at high rpm - Voltage is dropping. It is the original unit from 2003. Also, I'm pushing 3 fuel pumps. I ordered a high output alternator today. I'm hoping that is the issue. We'll see.

We started with 3 step colder plugs the previous week, but were getting some missing in the high rpms. 1 step colder plugs with a 0.022" gap and new coils fixed that issue. The missing is gone.

I was wondering if both exhaust cams were off one tooth, closing a little too late. It's highly unlikely both exhaust cams are off by one tooth while the intake cams are correct (we have verified the intake cams are correct by monitoring them with the Haltech data logging). But I was trying to think about what would give me (1) relatively low compression, (2) monster torque around 4k rpm and (3) drop in torque in high rpms. It seems like late opening/closing exhaust cams would do that, but I am merely speculating. The cam phasing probably is OK.

Next, we may hook up a pressure sensor to the exhaust side to see what kind of back pressure I am getting. It could be that reversion is the issue. XKR has the same turbo kit, but with GT35 turbos, and his torque holds strong. It could be the GT30 turbines are a little too small for my 4.0L motor. I'm not sure.

UPDATE: I just went through my logs from when I was on the dyno. It looks like my alternator is not keeping up at high rpm - Voltage is dropping. It is the original unit from 2003. Also, I'm pushing 3 fuel pumps. I ordered a high output alternator today. I'm hoping that is the issue. We'll see.

Last edited by ttg35fort; 02-16-2015 at 02:58 PM.

#173

Registered User

iTrader: (2)

The results are consistent. Also, AFR is consistent on both banks.

We started with 3 step colder plugs the previous week, but were getting some missing in the high rpms. 1 step colder plugs with a 0.022" gap and new coils fixed that issue. The missing is gone.

I was wondering if both exhaust cams were off one tooth, closing a little too late. It's highly unlikely both exhaust cams are off by one tooth while the intake cams are correct (we have verified the intake cams are correct by monitoring them with the Haltech data logging). But I was trying to think about what would give me (1) relatively low compression, (2) monster torque around 4k rpm and (3) drop in torque in high rpms. It seems like late opening/closing exhaust cams would do that, but I am merely speculating. The cam phasing probably is OK.

Next, we may hook up a pressure sensor to the exhaust side to see what kind of back pressure I am getting. It could be that reversion is the issue. XKR has the same turbo kit, but with GT35 turbos, and his torque holds strong. It could be the GT30 turbines are a little too small for my 4.0L motor. I'm not sure.

UPDATE: I just went through my logs from when I was on the dyno. It looks like my alternator is not keeping up at high rpm - Voltage is dropping. It is the original unit from 2003. Also, I'm pushing 3 fuel pumps. I ordered a high output alternator today. I'm hoping that is the issue. We'll see.

We started with 3 step colder plugs the previous week, but were getting some missing in the high rpms. 1 step colder plugs with a 0.022" gap and new coils fixed that issue. The missing is gone.

I was wondering if both exhaust cams were off one tooth, closing a little too late. It's highly unlikely both exhaust cams are off by one tooth while the intake cams are correct (we have verified the intake cams are correct by monitoring them with the Haltech data logging). But I was trying to think about what would give me (1) relatively low compression, (2) monster torque around 4k rpm and (3) drop in torque in high rpms. It seems like late opening/closing exhaust cams would do that, but I am merely speculating. The cam phasing probably is OK.

Next, we may hook up a pressure sensor to the exhaust side to see what kind of back pressure I am getting. It could be that reversion is the issue. XKR has the same turbo kit, but with GT35 turbos, and his torque holds strong. It could be the GT30 turbines are a little too small for my 4.0L motor. I'm not sure.

UPDATE: I just went through my logs from when I was on the dyno. It looks like my alternator is not keeping up at high rpm - Voltage is dropping. It is the original unit from 2003. Also, I'm pushing 3 fuel pumps. I ordered a high output alternator today. I'm hoping that is the issue. We'll see.

Make a new thread, so we don't hijack this one... And I'd love to see this build of yours! (Along side everyone else I'm sure). Also that way incase the alternator doesn't fix your issues, more people will be likely to chime in. I have 3 pumps too... I never really thought about what condition my alternator is in hahahaha

#174

Sorry about high jacking your thread, Raj.

I'll start a new thread after the next round of testing.

Resmarted, I thought the main fuel pump was holding steady, but after reviewing the logs, it was losing some pressure up top. The loss in pressure was offset by tuning the injector timing (we were making adjustments based on the AFR readings, not paying enough attention to the actual fuel pressure up top). So, the AFR was OK. Still, the motor was struggling up top. Maybe there was still some missing going on, but less apparent with the new spark plugs/coils than it was before. I'll update after we give the new alternator a try.

I'll start a new thread after the next round of testing.

Resmarted, I thought the main fuel pump was holding steady, but after reviewing the logs, it was losing some pressure up top. The loss in pressure was offset by tuning the injector timing (we were making adjustments based on the AFR readings, not paying enough attention to the actual fuel pressure up top). So, the AFR was OK. Still, the motor was struggling up top. Maybe there was still some missing going on, but less apparent with the new spark plugs/coils than it was before. I'll update after we give the new alternator a try.

Last edited by ttg35fort; 02-16-2015 at 04:15 PM.

#175

I don't think spark or fuel is the issue. It's airflow. The car makes power so the engine is fine. I would check only a few things.

1. You can have a boost leak or a failing turbo and still maintain boost. Do you have a nipple on the compressor or pre-IC piping for each turbo? Stick a pressure sensor on there and do a pull. If both turbos are consistent then your turbos are fine.

2. Do a smoke test to preclude a boost leak.

3. Disconnect after the downpipes and just do one pull. If no power gain, bolt up exhaust.

I believe your suspicions are correct. The combination of the manifold and small turbo housing on a 4L motor may be the underlying issue.

If the turbos are healthy, I say not to worry about it and enjoy the car.

1. You can have a boost leak or a failing turbo and still maintain boost. Do you have a nipple on the compressor or pre-IC piping for each turbo? Stick a pressure sensor on there and do a pull. If both turbos are consistent then your turbos are fine.

2. Do a smoke test to preclude a boost leak.

3. Disconnect after the downpipes and just do one pull. If no power gain, bolt up exhaust.

I believe your suspicions are correct. The combination of the manifold and small turbo housing on a 4L motor may be the underlying issue.

If the turbos are healthy, I say not to worry about it and enjoy the car.

Last edited by rcdash; 02-16-2015 at 04:28 PM.

#177

Registered User

iTrader: (2)

I don't think spark or fuel is the issue. It's airflow. The car makes power so the engine is fine. I would check only a few things.

1. You can have a boost leak or a failing turbo and still maintain boost. Do you have a nipple on the compressor or pre-IC piping for each turbo? Stick a pressure sensor on there and do a pull. If both turbos are consistent then your turbos are fine.

2. Do a smoke test to preclude a boost leak.

3. Disconnect after the downpipes and just do one pull. If no power gain, bolt up exhaust.

I believe your suspicions are correct. The combination of the manifold and small turbo housing on a 4L motor may be the underlying issue.

If the turbos are healthy, I say not to worry about it and enjoy the car.

1. You can have a boost leak or a failing turbo and still maintain boost. Do you have a nipple on the compressor or pre-IC piping for each turbo? Stick a pressure sensor on there and do a pull. If both turbos are consistent then your turbos are fine.

2. Do a smoke test to preclude a boost leak.

3. Disconnect after the downpipes and just do one pull. If no power gain, bolt up exhaust.

I believe your suspicions are correct. The combination of the manifold and small turbo housing on a 4L motor may be the underlying issue.

If the turbos are healthy, I say not to worry about it and enjoy the car.

It's common knowledge that logs are not going to flow as much as tubular, but this seems pretty drastic. Correct me if I'm misunderstanding this, but the power is dropping off to the point where the engine stops pulling? That really shouldn't be happening, even if the turbos are 'small'. Past 7k that would make a bit more sense, but this sounds like power after 5k before 6k just disappears. That sounds more serious than undersized turbos... But then again, I don't have any experience with stroked vq's.

#178

You are fine. Make sure your high amp alternator is not working simply by having an overdrive pulley. That just adds load to the belt system.

#179

People run similarly sized gt30's on sr20's all the time. And none of them choke like this...

It's common knowledge that logs are not going to flow as much as tubular, but this seems pretty drastic. Correct me if I'm misunderstanding this, but the power is dropping off to the point where the engine stops pulling? That really shouldn't be happening, even if the turbos are 'small'. Past 7k that would make a bit more sense, but this sounds like power after 5k before 6k just disappears. That sounds more serious than undersized turbos... But then again, I don't have any experience with stroked vq's.

It's common knowledge that logs are not going to flow as much as tubular, but this seems pretty drastic. Correct me if I'm misunderstanding this, but the power is dropping off to the point where the engine stops pulling? That really shouldn't be happening, even if the turbos are 'small'. Past 7k that would make a bit more sense, but this sounds like power after 5k before 6k just disappears. That sounds more serious than undersized turbos... But then again, I don't have any experience with stroked vq's.

We have not seen a dynograph so I cannot say for sure, but a SR20 with a GT30 and tubular manifold is going to make different power than a log manifold. I think that's the only difference we're seeing here except x 2 (4L and 2 turbos). Would need to the dynograph.

XKR had GT35s. Different story. There is an upgrade path: GT35s or a GTX turbo or billet compressor wheel. My GTX2867 turbo basically has an identical compressor map to the GT3071. The main difference is the tubular manifold.

Last edited by rcdash; 02-16-2015 at 06:05 PM.

#180

I looked at changing to the GTX3071 turbos before replacing my turbine housings. They looked too large to fit where my turbos are located. If we do not get the issue resolved, I may look at getting the SFR headers and GTX3071 turbos down the road sometime.

The weird thing is that the torque starts dropping right where the voltage hiccup occurs. The new alternator can't hurt.

The weird thing is that the torque starts dropping right where the voltage hiccup occurs. The new alternator can't hurt.

Last edited by ttg35fort; 02-17-2015 at 06:11 AM.