World's first broken diff stud

#41

ase dosnt mean anything in regards to physics, no offense ive passed ase master tech, ase master collision repair tech, and icar gold collision repair tech and it dosnt teach you any of the physics, it teachs the basics to fix things not determine why things are happening and what forces are involved. in fact around 90% of people who pass the ase's are nothing more then parts changers and couldnt build a car properly to save there lives sorry that isnt a good response. no offense but you need some experience if you had more then you would understand that the transmission in fact does not push on it because 99% of vehicles the 350z and g35 included are slip yoke and the driveshaft slides in and out of the tail shaft. i can tell you for a fact(ive built/building two of these cars now both high power builds) has about 5-6 inchs of forward and rearward play while still engaging the tailshaft splines. plus as i said the v35 or g35 has a carrier bearing which makes it impossible.

if your not talking about solid then you should quote who your referring to since the entire conversation is about how moving to solid mounts in absolutely no way effect the rear end stud and it is solely acted upon by the power the engine makes.

if your not talking about solid then you should quote who your referring to since the entire conversation is about how moving to solid mounts in absolutely no way effect the rear end stud and it is solely acted upon by the power the engine makes.

The whole thing moves, pushes back on the diff, it's all flexible with so much rubber, strange things happen. Nice job of assuming too. I passed that ASE, and the rest. I wouldnt be posting if I hadnt had a few drinks so I'll admit I could be wrong. I don't really care who's right, as a mechanic I research before I fix something. I don't assume my memory is working, there's alot to remember. i did not say solid, read again, was talking about op's statement of broken mounts, and then deciding to overengineer something without analyzing the situation better.

#42

Thread Starter

Registered User

iTrader: (7)

Joined: Jun 2007

Posts: 1,251

Likes: 1

From: Planet Kolob

You 2 are suppose to find me a pipe with a thick wall with a 14 mm ID, that does not come from a Goldman Sachs wearhouse. The reason why it happens is irrelevant since there is a sollution, but the cars are ****, that's why.

Last edited by Andrei; 09-12-2013 at 07:46 AM.

#43

Woah, hey now; what is this? I disappear for a few days for some devastating, soul crushing work; and I come back to find this once beautiful thread a small dick swinging contest? Come on now gentlemen. No one cares that you guys are part of the American Society of Echocardiography. I'm an engineer that admonishes high ranking, big dick swinging, self exalted genii on a daily basis. Do you guys care? I don't; truths and facts can come for the mouths of peasants, kings, genii, dolts, whatever. I took the time to carefully read what was written before this all became a different kind of entertaining; so now, back to the show.

Buddy, I see what your saying. Technically though; yeah, twist from the engine can transfer to the diff housing. Off the top of my head; friction is still a factor, definitely stiction also...If I sat around a little longer I could probably come up with few more; but they wouldn't be even close to significant enough. What was the point of mentioning any of this? To point out that your statements lack qualifiers. It may soften your "punch", but its a good idea to throw in a few qualifiers to validate a stance; never say never.

So we're talking about a twisting force coming from the engine/trans to the driveshaft, and the actual twist of the motor/trans itself; I follow. !!!!!!!!!!!!!!!!!!!!!!!!

... And I guess we finally arrive at the root of our disagreement. I apologize if you feel that I lead you to believe that I thought the solid motor mounts to be the root, or primary, cause of the diff stud failure. That is not my stance on this. I merely stated that solid mounts "could have contributed to the failure of the diff stud" and that they could have played, merely, a role larger than none "what so ever".

... And I guess we finally arrive at the root of our disagreement. I apologize if you feel that I lead you to believe that I thought the solid motor mounts to be the root, or primary, cause of the diff stud failure. That is not my stance on this. I merely stated that solid mounts "could have contributed to the failure of the diff stud" and that they could have played, merely, a role larger than none "what so ever".

Buddy! I'm sitting here spinning a this spool on this stick, and have no idea wtf this has to do with anything! Probably the worst, what is supposed to be; example of Newton's third law ever, but I get what you're trying get at. I like this, cause this is a good lead into the following;

I think part of this differentiation in perception is that you may be missing the the variable of how the "twist" is leaving the motor. When the engine/trans twists and rocks, what do you think is happening to the moving parts inside the motor generating this twist? When the motor rocks, do you think the engine adjusts timing and power to compensate for the change in engine position relative to the crank position, which is connected to the drivetrain? Heck no! If you rock that motor the torque and rate of torque being fed to the driveshaft is going to change; I hope you realize that. If you do, great! We're done here. If not, well...think about it. And yah, physics is there; whether you're interpreting correctly or not, it's there.

I agree with that thing about about energy! Except that I do notice it. I'm pretty sure you do too (or would if you've never went solid mounts). Not all the load goes back into the chassis though. This is a good segue back to what I had mentioned above. That load will also be thrown right onto the pistons. I hope your understand that, and if you do, do you really think the torque and rate of torque to the drivetrain will remain the same between rocking, rocking the other way, and no rocking at all?

Except that I do notice it. I'm pretty sure you do too (or would if you've never went solid mounts). Not all the load goes back into the chassis though. This is a good segue back to what I had mentioned above. That load will also be thrown right onto the pistons. I hope your understand that, and if you do, do you really think the torque and rate of torque to the drivetrain will remain the same between rocking, rocking the other way, and no rocking at all?

Yah, I wish that was my issue.

If you had simply said "stock is stiff enough to act like solid already" from the the beginning, I would have just been like... actually... I probably wouldn't have said anything. You're entitled to your opinion. People don't notice increased noise cause people suck.

The stud doesn't have the break by "side to side" movement to have it come from the engine. It can still break as how you described in your earlier post on "what ACTUALLY breaks the stud" except instead of a mere launch, you also get an extra, abrupt, spike in rate of torque from what was described above. Damn I'm sleepy.

your missing a large part of what is going on in a vehicle chassis, all the twisting from the engine and transmission CANNOT be transferred to the differential housing, the only thing that connects them is the drive shaft, which spins inside both the transmission housing and the differential housing aka pumpkin.

... And I guess we finally arrive at the root of our disagreement. I apologize if you feel that I lead you to believe that I thought the solid motor mounts to be the root, or primary, cause of the diff stud failure. That is not my stance on this. I merely stated that solid mounts "could have contributed to the failure of the diff stud" and that they could have played, merely, a role larger than none "what so ever".

... And I guess we finally arrive at the root of our disagreement. I apologize if you feel that I lead you to believe that I thought the solid motor mounts to be the root, or primary, cause of the diff stud failure. That is not my stance on this. I merely stated that solid mounts "could have contributed to the failure of the diff stud" and that they could have played, merely, a role larger than none "what so ever". want a example? grab a larger spool of wire, stick a fender washer or bearing(if you have one) into the center section and slide a smooth rod into the washer or bearing then spin the opposite end with your hand. thats exactly how the forces are being imparted by the driveshaft and its spinning in the opposite direction that the engine is rocking,

next no forces dont vanish when transferred to the chassis the chassis flex's as well some more then others impossible to eliminate all of it(and in some cases it helps improve times even) its impossible for energy to vanish or be destroyed your simply converting it, you simply dont notice it because it is spread over a much larger area then motor mounts.

Except that I do notice it. I'm pretty sure you do too (or would if you've never went solid mounts). Not all the load goes back into the chassis though. This is a good segue back to what I had mentioned above. That load will also be thrown right onto the pistons. I hope your understand that, and if you do, do you really think the torque and rate of torque to the drivetrain will remain the same between rocking, rocking the other way, and no rocking at all?

Except that I do notice it. I'm pretty sure you do too (or would if you've never went solid mounts). Not all the load goes back into the chassis though. This is a good segue back to what I had mentioned above. That load will also be thrown right onto the pistons. I hope your understand that, and if you do, do you really think the torque and rate of torque to the drivetrain will remain the same between rocking, rocking the other way, and no rocking at all?the issue your having is visualizing the basic principles of physics in that the engine is producing two seperate kinetic forces each equal, one is dissipated through the motor and transmission mounts, the other is dissipated through the drivetrain to the tires and is in no way affected by the motor mounts.

you will also notice that the stud broken isnt broken by side to side movements like the engine does, it happens from the fact that the pumpkin trys to twist the flange up and the cover down when the driveshaft imparts force on it, its the basics on how ladder bars and a four link work and is 100% a function of power output not motor mounts.

#44

your second point is begging to understand then you throw it right out the window with your third one, mayby im just a poor teacher but as i said a bunch of times there are two different twisting forces going on at the engine, but only one out of the transmission(the driveshaft) mayby ill try to make a diagram later to help you understand better how the forces are actually happening.

the rate or torque and torque only are effected when it rocks once it hits its limit it goes right back up(yes i am well versed in the fact that torque is nothing more then potential power and once something is moving that drops) but i think we already agreed that solid motor mounts eliminate the rocking motion.

also no not 100% goes into the the chassis we all know that energy transformation isnt efficient by any means and its converted to several different types of energy. however you can dissipate energy to something that its not connected too. what your lacking some understanding in is that the load on the pistons is from the rear end not the engine block. the rocking of the engine is caused by acceleration and inertia not the power of the engine, you can disconnect everything from the engine and rev it, its not going to make hardly any power due to no load yet the engine still rocks(and often rocks harder due to quicker acceleration) thats the significant difference here. the rocking of the engine is caused by the change in acceleration and the inertia in relation to the rotation of the crankshaft, the pistons would actually make the engine bounce up and down. your mistake is your viewing it as only one reaction going on.

ill disagree with you on the noise thing too, i drove my car before and after and been building cars for years, ive gone solid on several other platforms, there is virtually no noise change and i even drove without the radio on when i first did installs because well you cant hear any possible issues with the radio on.

the rate or torque and torque only are effected when it rocks once it hits its limit it goes right back up(yes i am well versed in the fact that torque is nothing more then potential power and once something is moving that drops) but i think we already agreed that solid motor mounts eliminate the rocking motion.

also no not 100% goes into the the chassis we all know that energy transformation isnt efficient by any means and its converted to several different types of energy. however you can dissipate energy to something that its not connected too. what your lacking some understanding in is that the load on the pistons is from the rear end not the engine block. the rocking of the engine is caused by acceleration and inertia not the power of the engine, you can disconnect everything from the engine and rev it, its not going to make hardly any power due to no load yet the engine still rocks(and often rocks harder due to quicker acceleration) thats the significant difference here. the rocking of the engine is caused by the change in acceleration and the inertia in relation to the rotation of the crankshaft, the pistons would actually make the engine bounce up and down. your mistake is your viewing it as only one reaction going on.

ill disagree with you on the noise thing too, i drove my car before and after and been building cars for years, ive gone solid on several other platforms, there is virtually no noise change and i even drove without the radio on when i first did installs because well you cant hear any possible issues with the radio on.

Woah, hey now; what is this? I disappear for a few days for some devastating, soul crushing work; and I come back to find this once beautiful thread a small dick swinging contest? Come on now gentlemen. No one cares that you guys are part of the American Society of Echocardiography. I'm an engineer that admonishes high ranking, big dick swinging, self exalted genii on a daily basis. Do you guys care? I don't; truths and facts can come for the mouths of peasants, kings, genii, dolts, whatever. I took the time to carefully read what was written before this all became a different kind of entertaining; so now, back to the show.

Buddy, I see what your saying. Technically though; yeah, twist from the engine can transfer to the diff housing. Off the top of my head; friction is still a factor, definitely stiction also...If I sat around a little longer I could probably come up with few more; but they wouldn't be even close to significant enough. What was the point of mentioning any of this? To point out that your statements lack qualifiers. It may soften your "punch", but its a good idea to throw in a few qualifiers to validate a stance; never say never.

So we're talking about a twisting force coming from the engine/trans to the driveshaft, and the actual twist of the motor/trans itself; I follow. !!!!!!!!!!!!!!!!!!!!!!!!

... And I guess we finally arrive at the root of our disagreement. I apologize if you feel that I lead you to believe that I thought the solid motor mounts to be the root, or primary, cause of the diff stud failure. That is not my stance on this. I merely stated that solid mounts "could have contributed to the failure of the diff stud" and that they could have played, merely, a role larger than none "what so ever".

... And I guess we finally arrive at the root of our disagreement. I apologize if you feel that I lead you to believe that I thought the solid motor mounts to be the root, or primary, cause of the diff stud failure. That is not my stance on this. I merely stated that solid mounts "could have contributed to the failure of the diff stud" and that they could have played, merely, a role larger than none "what so ever".

Buddy! I'm sitting here spinning a this spool on this stick, and have no idea wtf this has to do with anything! Probably the worst, what is supposed to be; example of Newton's third law ever, but I get what you're trying get at. I like this, cause this is a good lead into the following;

I think part of this differentiation in perception is that you may be missing the the variable of how the "twist" is leaving the motor. When the engine/trans twists and rocks, what do you think is happening to the moving parts inside the motor generating this twist? When the motor rocks, do you think the engine adjusts timing and power to compensate for the change in engine position relative to the crank position, which is connected to the drivetrain? Heck no! If you rock that motor the torque and rate of torque being fed to the driveshaft is going to change; I hope you realize that. If you do, great! We're done here. If not, well...think about it. And yah, physics is there; whether you're interpreting correctly or not, it's there.

I agree with that thing about about energy! Except that I do notice it. I'm pretty sure you do too (or would if you've never went solid mounts). Not all the load goes back into the chassis though. This is a good segue back to what I had mentioned above. That load will also be thrown right onto the pistons. I hope your understand that, and if you do, do you really think the torque and rate of torque to the drivetrain will remain the same between rocking, rocking the other way, and no rocking at all?

Except that I do notice it. I'm pretty sure you do too (or would if you've never went solid mounts). Not all the load goes back into the chassis though. This is a good segue back to what I had mentioned above. That load will also be thrown right onto the pistons. I hope your understand that, and if you do, do you really think the torque and rate of torque to the drivetrain will remain the same between rocking, rocking the other way, and no rocking at all?

Yah, I wish that was my issue.

If you had simply said "stock is stiff enough to act like solid already" from the the beginning, I would have just been like... actually... I probably wouldn't have said anything. You're entitled to your opinion. People don't notice increased noise cause people suck.

The stud doesn't have the break by "side to side" movement to have it come from the engine. It can still break as how you described in your earlier post on "what ACTUALLY breaks the stud" except instead of a mere launch, you also get an extra, abrupt, spike in rate of torque from what was described above. Damn I'm sleepy.

Buddy, I see what your saying. Technically though; yeah, twist from the engine can transfer to the diff housing. Off the top of my head; friction is still a factor, definitely stiction also...If I sat around a little longer I could probably come up with few more; but they wouldn't be even close to significant enough. What was the point of mentioning any of this? To point out that your statements lack qualifiers. It may soften your "punch", but its a good idea to throw in a few qualifiers to validate a stance; never say never.

So we're talking about a twisting force coming from the engine/trans to the driveshaft, and the actual twist of the motor/trans itself; I follow. !!!!!!!!!!!!!!!!!!!!!!!!

... And I guess we finally arrive at the root of our disagreement. I apologize if you feel that I lead you to believe that I thought the solid motor mounts to be the root, or primary, cause of the diff stud failure. That is not my stance on this. I merely stated that solid mounts "could have contributed to the failure of the diff stud" and that they could have played, merely, a role larger than none "what so ever".

... And I guess we finally arrive at the root of our disagreement. I apologize if you feel that I lead you to believe that I thought the solid motor mounts to be the root, or primary, cause of the diff stud failure. That is not my stance on this. I merely stated that solid mounts "could have contributed to the failure of the diff stud" and that they could have played, merely, a role larger than none "what so ever". Buddy! I'm sitting here spinning a this spool on this stick, and have no idea wtf this has to do with anything! Probably the worst, what is supposed to be; example of Newton's third law ever, but I get what you're trying get at. I like this, cause this is a good lead into the following;

I think part of this differentiation in perception is that you may be missing the the variable of how the "twist" is leaving the motor. When the engine/trans twists and rocks, what do you think is happening to the moving parts inside the motor generating this twist? When the motor rocks, do you think the engine adjusts timing and power to compensate for the change in engine position relative to the crank position, which is connected to the drivetrain? Heck no! If you rock that motor the torque and rate of torque being fed to the driveshaft is going to change; I hope you realize that. If you do, great! We're done here. If not, well...think about it. And yah, physics is there; whether you're interpreting correctly or not, it's there.

I agree with that thing about about energy!

Except that I do notice it. I'm pretty sure you do too (or would if you've never went solid mounts). Not all the load goes back into the chassis though. This is a good segue back to what I had mentioned above. That load will also be thrown right onto the pistons. I hope your understand that, and if you do, do you really think the torque and rate of torque to the drivetrain will remain the same between rocking, rocking the other way, and no rocking at all?

Except that I do notice it. I'm pretty sure you do too (or would if you've never went solid mounts). Not all the load goes back into the chassis though. This is a good segue back to what I had mentioned above. That load will also be thrown right onto the pistons. I hope your understand that, and if you do, do you really think the torque and rate of torque to the drivetrain will remain the same between rocking, rocking the other way, and no rocking at all?Yah, I wish that was my issue.

If you had simply said "stock is stiff enough to act like solid already" from the the beginning, I would have just been like... actually... I probably wouldn't have said anything. You're entitled to your opinion. People don't notice increased noise cause people suck.

The stud doesn't have the break by "side to side" movement to have it come from the engine. It can still break as how you described in your earlier post on "what ACTUALLY breaks the stud" except instead of a mere launch, you also get an extra, abrupt, spike in rate of torque from what was described above. Damn I'm sleepy.

#45

your second point is begging to understand then you throw it right out the window with your third one, mayby im just a poor teacher but as i said a bunch of times there are two different twisting forces going on at the engine, but only one out of the transmission(the driveshaft) mayby ill try to make a diagram later to help you understand better how the forces are actually happening.

the rate or torque and torque only are effected when it rocks once it hits its limit it goes right back up(yes i am well versed in the fact that torque is nothing more then potential power and once something is moving that drops) but i think we already agreed that solid motor mounts eliminate the rocking motion.

also no not 100% goes into the the chassis we all know that energy transformation isnt efficient by any means and its converted to several different types of energy. however you can dissipate energy to something that its not connected too. what your lacking some understanding in is that the load on the pistons is from the rear end not the engine block. the rocking of the engine is caused by acceleration and inertia not the power of the engine, you can disconnect everything from the engine and rev it, its not going to make hardly any power due to no load yet the engine still rocks(and often rocks harder due to quicker acceleration) thats the significant difference here. the rocking of the engine is caused by the change in acceleration and the inertia in relation to the rotation of the crankshaft, the pistons would actually make the engine bounce up and down. your mistake is your viewing it as only one reaction going on.

ill disagree with you on the noise thing too, i drove my car before and after and been building cars for years, ive gone solid on several other platforms, there is virtually no noise change and i even drove without the radio on when i first did installs because well you cant hear any possible issues with the radio on.

#46

well ask them how it changes it then and to explain it? at the end of the day no matter what mounts they have a limit to what they can move and once they hit it that engine is no longer moving it has its full torque, and the crank continues to rotate with absolutely no change because the engine is slightly cocked, the crankshaft still spins 360 degrees as always, there is still nothing that attachs the housings of the transmission and engine to the rear differential to impart the twisting force on it from those items(thats all the mounts change is the amount of twist the block and case can do, the crank still spins exactly the same) if this where a corvette with a torque tube then sure, but its not it has a driveshaft. it also has no effect in the y axis since the driveshaft slides in and out of the housing, it has no effect on the x axis because the driveshaft has U joints and the same for z axis. so have them explain how solid motor mounts magically cause force to be imparted. no offense mayby you do know those people, but dont blame me if i dont actually believe it 99.5% of the internet says they consulted a expert when they get involved in a arguement online. i havnt ive spoken on person experience

your second point is what really gets me your comments make your point come across as if you believe the engine is in a constant state of motion, which it is not they have a limit still the movement is almost nill, the reason for the solids is because rubber and poly break at higher power when your increasing the initial action of the crank and thus increasing the reaction that the block imparts. thats what this entire conversation is about is the reaction, which is the only thing the motor mounts have an effect on is the reaction.

your second point is what really gets me your comments make your point come across as if you believe the engine is in a constant state of motion, which it is not they have a limit still the movement is almost nill, the reason for the solids is because rubber and poly break at higher power when your increasing the initial action of the crank and thus increasing the reaction that the block imparts. thats what this entire conversation is about is the reaction, which is the only thing the motor mounts have an effect on is the reaction.

Yeah, sorry sir. I mean, its just so clear to me. I'm having a hard time (to say the least) seeing solid mounts changing absolutely nothing to the stress on the driveshaft and/or after. It seems pretty simple. I don't know what the problem is. I've gone to colleagues with this, presenting it from your position. I wish they could tell me I'm wrong (in present context) so they could explain it, but they agreed that there would be a change. And not that it matters to me, but three are engineers (two mechanical) and one is a physicist (funny).

Hey now! Look at what you said here. So you say you know that "once something is moving" torque drops, BUT we agreed that solid motor mounts eliminate that movement. So guess what happens to that torque when you go from mounts that allowed movement, to mounts to allow almost none? You said it yourself sir. This is what I've been getting at. Although it may not be by much, that torque and rate of won't remain the same. I think we might just have our conclusion here. Unless you feel like being stubborn, which is absolutely human; so don't get defensive.

The rocking of the engine isn't caused by the power of the engine? It's caused by acceleration and inertia? And where does this acceleration and inertia come from? Would it exist without "the power of the engine"? I went over this paragraph multiple times and it only makes my head hurt. Sorry, this was my fault for getting into where the energy goes; going off on tangents. What's important was my previous point.

Yeah, I didn't really care about the noise claim. That paragraph was more about if you had just said OEM bushings are too damn hard for it to matter. If you can't hear a difference you can't hear it. Thats cool.

Hey now! Look at what you said here. So you say you know that "once something is moving" torque drops, BUT we agreed that solid motor mounts eliminate that movement. So guess what happens to that torque when you go from mounts that allowed movement, to mounts to allow almost none? You said it yourself sir. This is what I've been getting at. Although it may not be by much, that torque and rate of won't remain the same. I think we might just have our conclusion here. Unless you feel like being stubborn, which is absolutely human; so don't get defensive.

The rocking of the engine isn't caused by the power of the engine? It's caused by acceleration and inertia? And where does this acceleration and inertia come from? Would it exist without "the power of the engine"? I went over this paragraph multiple times and it only makes my head hurt. Sorry, this was my fault for getting into where the energy goes; going off on tangents. What's important was my previous point.

Yeah, I didn't really care about the noise claim. That paragraph was more about if you had just said OEM bushings are too damn hard for it to matter. If you can't hear a difference you can't hear it. Thats cool.

#47

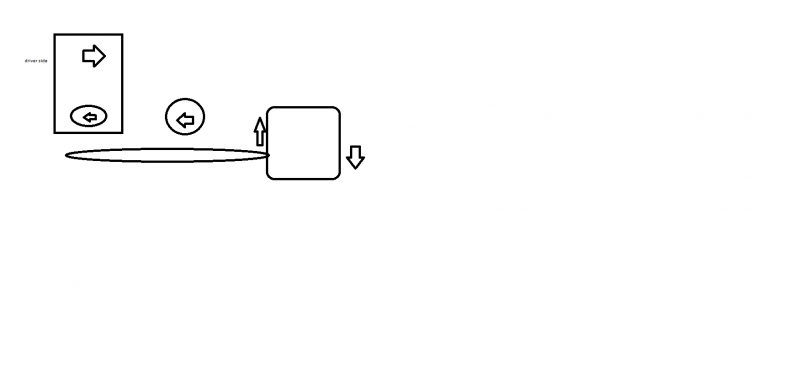

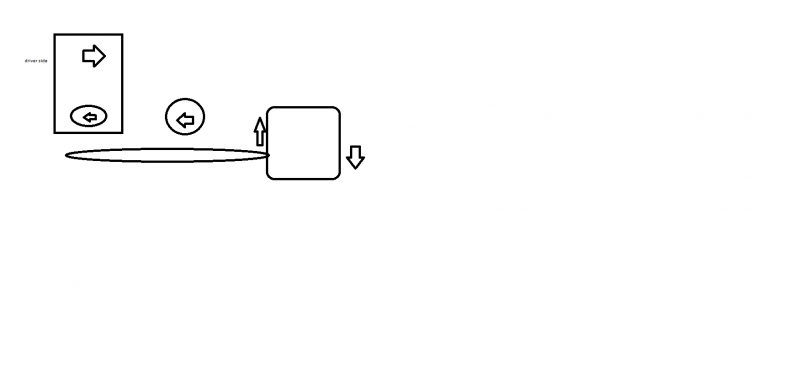

went ahead and made a diagram what im talking about the first is both the crank and block)or trans and output shaft gona act the same way since they are all bolted togeather)

the crank rotates one way, the engine trys to rotate the other(same for transmission and output shaft) the motor mounts stop that. the second picture is the driveshaft, it has no housing that it rides inside, its equal and opposite reaction is happening to the air not a casing because it has none that negates and force the case and block COULD impart because theres nothing to connect them togeather the only parts put togeather rotate inside of housings. once you get to the rear differential then the deal returns you have the pinion try to turn one way and the momentum, power, and inertia from that causes the housing try to turn the other way. heres the thing though, that turns in a way that does not affect that bolt at all, the only thing it could do is tighten or loosen it and would require completely turning the housing, the bolt dosnt break in the correct axis.

now the LAST picture shows how the bolt actually breaks, that is a completely different axis from what the driveshaft imparts on it. what actually causes this type of housing rotation? the tires, suspension, and axles, completely removed from the engine several times the motor mounts have absolutely no effect on this. by your theory race cars could gain traction by swapping motor mounts which is absolutely not true. if you indeed DO know those engineers you should probably stay away from them, better yet go talk to actual automotive mechanical engineers and physicists who actually apply things, race crew chiefs too no offense but ive discredited what you have said several times and you still attempt to argue it you wont find a single person who has actually built a car who will agree with you.

the crank rotates one way, the engine trys to rotate the other(same for transmission and output shaft) the motor mounts stop that. the second picture is the driveshaft, it has no housing that it rides inside, its equal and opposite reaction is happening to the air not a casing because it has none that negates and force the case and block COULD impart because theres nothing to connect them togeather the only parts put togeather rotate inside of housings. once you get to the rear differential then the deal returns you have the pinion try to turn one way and the momentum, power, and inertia from that causes the housing try to turn the other way. heres the thing though, that turns in a way that does not affect that bolt at all, the only thing it could do is tighten or loosen it and would require completely turning the housing, the bolt dosnt break in the correct axis.

now the LAST picture shows how the bolt actually breaks, that is a completely different axis from what the driveshaft imparts on it. what actually causes this type of housing rotation? the tires, suspension, and axles, completely removed from the engine several times the motor mounts have absolutely no effect on this. by your theory race cars could gain traction by swapping motor mounts which is absolutely not true. if you indeed DO know those engineers you should probably stay away from them, better yet go talk to actual automotive mechanical engineers and physicists who actually apply things, race crew chiefs too no offense but ive discredited what you have said several times and you still attempt to argue it you wont find a single person who has actually built a car who will agree with you.

#48

From what I'm seeing, that would take quite a bit more effort than I would care to ask them for. We'll put that idea in the "Plan C" pile; I'd rather not be a bother.

A point I was trying to make was that the "full torque" will come on a lot faster with the solid mounts then with OEM squishable mounts. You agreed the engine movement would drop the torque, and yes when the motor stops moving, the torque will climb again; but the softer mounts would spread the rate of "full torque" applied to the drivetrain over more time then with solid mounts where the rate of torque applied will be more of an instant spike. The faster you swing that hammer, the more likely you'll break stuff. Especially compared to a slower swing with the same weight behind it. And I think I know what you'er thinking: yeah, but that still ain't going to do **** to that diff stud. Well, lets move on below...

I'm not sure if you saw, but if you look in my second post responding to you, you'll see that I agree with your theory on the mode of failure. I hope this is a breakthrough but; I never said the stud broke from the twist from the engine/trans. No, that twist, longitudinally, along that axis, won't be be able to get anywhere near breaking that stud. Please keep in mind I agree with your failure mode. My objection is that you said solid mounts have not effect what so ever. Following your failure mode, the more drastic spike in the rate of torque contributes to the the "increase in force" you were talking about that caused the failure.

I refer you to my first comment of this post.

None taken. I can assure you I do know these people, as I had mentioned; they're colleagues in my field or simular. I went to school and/or worked with them in one way or another. Then again, I suppose you're think i'm lying; and thats fair. It was a mistake even mentioning it; my apologies.

I refer you to my second response in this post.

Yup, there's a lot of benefits to solid mounts... Sorry, i'm out of time, and I'm going to have to reread the part about.... "reaction" about 15-20 times.

at the end of the day no matter what mounts they have a limit to what they can move and once they hit it that engine is no longer moving it has its full torque, and the crank continues to rotate with absolutely no change because the engine is slightly cocked, the crankshaft still spins 360 degrees as always,

there is still nothing that attachs the housings of the transmission and engine to the rear differential to impart the twisting force on it from those items(thats all the mounts change is the amount of twist the block and case can do, the crank still spins exactly the same) if this where a corvette with a torque tube then sure, but its not it has a driveshaft. it also has no effect in the y axis since the driveshaft slides in and out of the housing, it has no effect on the x axis because the driveshaft has U joints and the same for z axis.

the reason for the solids is because rubber and poly break at higher power when your increasing the initial action of the crank and thus increasing the reaction that the block imparts. thats what this entire conversation is about is the reaction, which is the only thing the motor mounts have an effect on is the reaction.

#50

Thread Starter

Registered User

iTrader: (7)

Joined: Jun 2007

Posts: 1,251

Likes: 1

From: Planet Kolob

UPDATE: I have parts on backorder for the past 2 weeks. 2 R51 cover studs one is just extra since it's cheap, a breather tube for the cover, and 2 nuts for the OEM stud. I just ordered 2 pipes to use as a bushing, the 0.546 ID one, and one with a thinner wall and a 0.622 ID.

Local dealers do not have the R51 stud in stock, so I have to wait for it anyway.

Since aftermarket bolts and studs have a slightly smaller OD than Nissan ones, a M14x1.5 bolt or stud might just work with the 0.546 pipe. I plan to cut the cap off a M14x1.5 bolt and use it as a stud, and fix the thread. Right now Fastenal or McMaster-Carr don't seem to have any fully threaded bolts that are long enough, but they had them before. They both have a fully threaded rod in M14x1.5, but no flange or lock nuts with a 1.5mm thread pitch which is odd.

Local dealers do not have the R51 stud in stock, so I have to wait for it anyway.

Since aftermarket bolts and studs have a slightly smaller OD than Nissan ones, a M14x1.5 bolt or stud might just work with the 0.546 pipe. I plan to cut the cap off a M14x1.5 bolt and use it as a stud, and fix the thread. Right now Fastenal or McMaster-Carr don't seem to have any fully threaded bolts that are long enough, but they had them before. They both have a fully threaded rod in M14x1.5, but no flange or lock nuts with a 1.5mm thread pitch which is odd.

Last edited by Andrei; 10-20-2013 at 03:38 PM.

#51

Thread Starter

Registered User

iTrader: (7)

Joined: Jun 2007

Posts: 1,251

Likes: 1

From: Planet Kolob

UPDATE: The pipe with the 0.546 ID barely fits a M14x1.5 bolt or stud, 2.0 thread pitch fits easier. Here are some comparison pictures between 0.546 with a thick wall, and 0.622 with thinner wall. The rod has to be threaded into the small ID pipe but it does work. The rod is weak, low carbon steel, so threading it in instead of pressing it will work.

#53

Thread Starter

Registered User

iTrader: (7)

Joined: Jun 2007

Posts: 1,251

Likes: 1

From: Planet Kolob

I got the stud today, the stud nut x2 and the breather, and worked for about 2 hours on it. The stud has a M16x2.0 size for the FD cover which what I originally thought, but that's what I get for using a ruler to measure the stud hole diameter. The nut size is M14x1.5 and both sizes are bigger than the V35/Z33 stud. The good news is that Fastenal has class 10.9 cap bolts that are fully threaded in 300 mm length with a M16x2.0 size.

Also the SPL bushing might have to be drilled out some to accept the larger stud, and I didn't have time to see if it would thread in. SPL could machine some rear FD bushings to accept the R51 stud.

Fastenal M16x2.0

And the 0.622 ID pipe fits the M16x2.0 stud end perfectly. I put the R51 cover on with no problem but I didn't get a pic.

Also the SPL bushing might have to be drilled out some to accept the larger stud, and I didn't have time to see if it would thread in. SPL could machine some rear FD bushings to accept the R51 stud.

Fastenal M16x2.0

And the 0.622 ID pipe fits the M16x2.0 stud end perfectly. I put the R51 cover on with no problem but I didn't get a pic.

Last edited by Andrei; 11-01-2013 at 05:25 PM.

#54

One way to think about things is that our drivetrain has fuses, and dampeners that help prevent the fuses from popping. Engine mounts, trans mounts, and diff bushings are the dampeners. Driveshaft, diff stud, and axles are the fuses. You make the engine mounts solid, that puts more peak stress on the driveshaft, diff and axles. Solid diff mounts and motor mounts? That puts all the shock stress on the axles. Basic physics make it clear that solid motor mounts could very well contribute to a diff stud failure

Last edited by djamps; 11-01-2013 at 06:36 PM.

#55

we gona start this again? w/e i give up you guys can keep thinking that and keep being wrong end of the day i can only help people, they dont wanna listen then ill gladly keep accepting money to do it for them.

#56

i will leave this here however which backs up what i say in that the movement of the engine rocking is to the passenger side, opposite of what the crank spins, if solid engine mounts had any affect on the rear diff AT ALL then the rear end would be twisting to the passanger side also, but it dosnt it turns towards the driver side because the engine block itself is for all intents and purposes when it comes to physics completely disconnected from the rear end, the flex in the U joints of the drive shaft ensure that 100% http://www.carcraft.com/techarticles...e/viewall.html

THIS will show you what REALLY breaks that bolt however, it is the only force acting on that bolt and comes from the tire trying to turn and the rear end resisting it, mid plate, solid mounts, poly, rubber or hell just setting the engine there has 0 to do with it. engine operates on a horizontal twisting force, the bolt is broken on a verticle twisting force.

http://www.how-to-build-hotrods.com/traction-bars.html

http://www.popularhotrodding.com/tec...pension_guide/

if you still cant get that then dont try setting up your suspension yourself you will put yourself in danger let a professional do it.

and dont start with the "they are domestics" or "they use a different suspension" the forces in play are exactly the same

THIS will show you what REALLY breaks that bolt however, it is the only force acting on that bolt and comes from the tire trying to turn and the rear end resisting it, mid plate, solid mounts, poly, rubber or hell just setting the engine there has 0 to do with it. engine operates on a horizontal twisting force, the bolt is broken on a verticle twisting force.

http://www.how-to-build-hotrods.com/traction-bars.html

http://www.popularhotrodding.com/tec...pension_guide/

if you still cant get that then dont try setting up your suspension yourself you will put yourself in danger let a professional do it.

and dont start with the "they are domestics" or "they use a different suspension" the forces in play are exactly the same

Last edited by jerryd87; 11-01-2013 at 11:40 PM.

#57

Thread Starter

Registered User

iTrader: (7)

Joined: Jun 2007

Posts: 1,251

Likes: 1

From: Planet Kolob

I found out today that the subframe is damaged and the bolts for the front FD bushings no longer line up with the subframe bolt holes. The subframe mounting holes are pulled out at an angle, so the mounting points are not straight anymore, making it impossible to put in the bolts. I knew since it happened that it might have pulled out the threaded inserts inside the subframe. I also tried M12 bolts which have a smaller diameter and tried to grab them with a lock nut front the top of the subframe, and the bolts go through all the way at a 30 degree angle but do not go through when they also have to go through the front SPL FD bushings. I also tried bending them and still did not go through.

I'll be getting a used subframe, but it will take a week before I can put it in next Saturday. And I'm stuck in a rental again, and I totaled the Prizm hydroplaning. It was a good car even though it dropped a valve on 4, and I planned to change the engine in that too to keep it.

I'll be getting a used subframe, but it will take a week before I can put it in next Saturday. And I'm stuck in a rental again, and I totaled the Prizm hydroplaning. It was a good car even though it dropped a valve on 4, and I planned to change the engine in that too to keep it.

Last edited by Andrei; 11-02-2013 at 05:50 PM.

#58

Thread Starter

Registered User

iTrader: (7)

Joined: Jun 2007

Posts: 1,251

Likes: 1

From: Planet Kolob

One way to think about things is that our drivetrain has fuses, and dampeners that help prevent the fuses from popping. Engine mounts, trans mounts, and diff bushings are the dampeners. Driveshaft, diff stud, and axles are the fuses. You make the engine mounts solid, that puts more peak stress on the driveshaft, diff and axles. Solid diff mounts and motor mounts? That puts all the shock stress on the axles. Basic physics make it clear that solid motor mounts could very well contribute to a diff stud failure

Or just lose an axle or both launching the car and pull over because you still can. I really wish it was the axles that broke instead because those are a dime a dozen. And in the end, as far as the V35/Z33, FM platform, this is what happens when cars are being built by a company that was nearly bankrupt.

And also consider that if the FD would of had 4 mounting points from the beginning which would of cost next to nothing additionally, this would of never happened, which is why they put 4 on the R51 Pathfinder in 2003 and 2004 when it was being built. Another piece of **** that had a multitude of problems, probably until the end of production last year.

Even though the R51 was in production until 2012 next door in Smyrna, Tennessee, I still had to wait 3 weeks to get that stud, and if I would of got it the same week I ordered it, I would still have my Prizm.

Last edited by Andrei; 11-03-2013 at 05:49 AM.

#59

Personally the only thing I'd make solid is the diff mounts so it can't move at all, period. Ever since my OEM bushing exploded, and the subsequent poly bushings failed the 2nd time at the track (and took out the stud), I have been running the SPL solid mounts + the SP brace and haven't had any issues, 1.6 60ft's all day long. 100's of passes since and still on the original axles. To protect the drivetrain and eliminate wheel hop I only run bias plies on the track though.

#60

Thread Starter

Registered User

iTrader: (7)

Joined: Jun 2007

Posts: 1,251

Likes: 1

From: Planet Kolob

If only Nissan would of made the compression rod bushings as tough as the subframe bushings, but what they can do, hanging a final drive that weighs 100 lbs + in the Infiniti Q50 with an M14 stud has never been so profitable. And a visible canister muffler used as an air diffuser on a 2014 $60k car makes the rear end look like a Nissan Versa.

Anyway, I got a used subframe and removed the 2 large bushings in it in 1 hour by cutting and pealing them out. Still have the 2 smaller ones. It's off an 03 sedan and it's suppose to be off an 05, but I wasn't there to inspect it when it was delivered. Suppose to be grade "A" and it has some scratches along the bottom and plenty of dried up yellow clay/dirt on it.

The 03 is not the same quality as the 05 subframes, and as an example the metal inserts for the front FD bushing bolts that got pulled out of my 05 subframe are welded inside the subframe. On the 03 they are loose and only tighten when the bolts are torqued in. It was 135 delivered, but I would of paid 200 for an 05 one.

Last time I'm buying anything from LKQ. I'm very disappointed and I don't like paying money to be lied to. This isn't a mix up on their end.

Anyway, I got a used subframe and removed the 2 large bushings in it in 1 hour by cutting and pealing them out. Still have the 2 smaller ones. It's off an 03 sedan and it's suppose to be off an 05, but I wasn't there to inspect it when it was delivered. Suppose to be grade "A" and it has some scratches along the bottom and plenty of dried up yellow clay/dirt on it.

The 03 is not the same quality as the 05 subframes, and as an example the metal inserts for the front FD bushing bolts that got pulled out of my 05 subframe are welded inside the subframe. On the 03 they are loose and only tighten when the bolts are torqued in. It was 135 delivered, but I would of paid 200 for an 05 one.

Last time I'm buying anything from LKQ. I'm very disappointed and I don't like paying money to be lied to. This isn't a mix up on their end.

Last edited by Andrei; 11-09-2013 at 07:26 PM.