200+ MPH 350Z build thread

#22

My appologies, I spent 3 hours this morning typing out a few pages of this story, only to have my POS laptop, lock up and dump all of it. dont know if ill have time at work today to redo all of it, but ill try. If not I promise that I will have a bunch of info on here this weekend, sorry for the delay.

#23

Sorry for the delay, been crazy busy at work and my laptop has been in the shop and I just got it back yesterday.

So here goes:

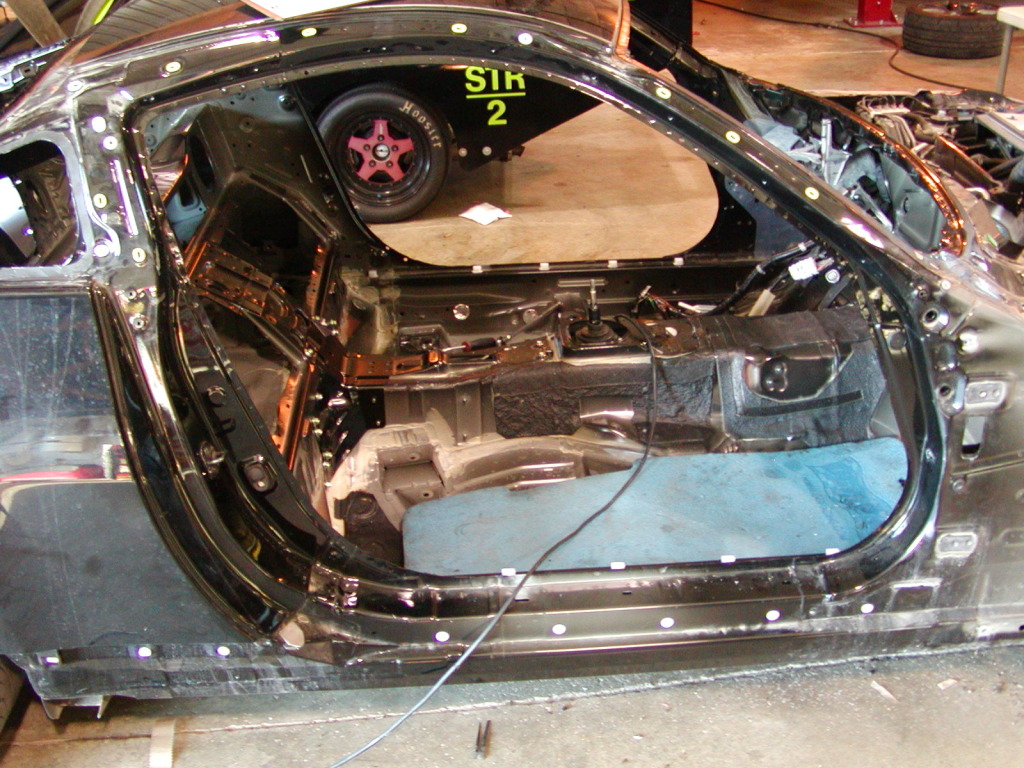

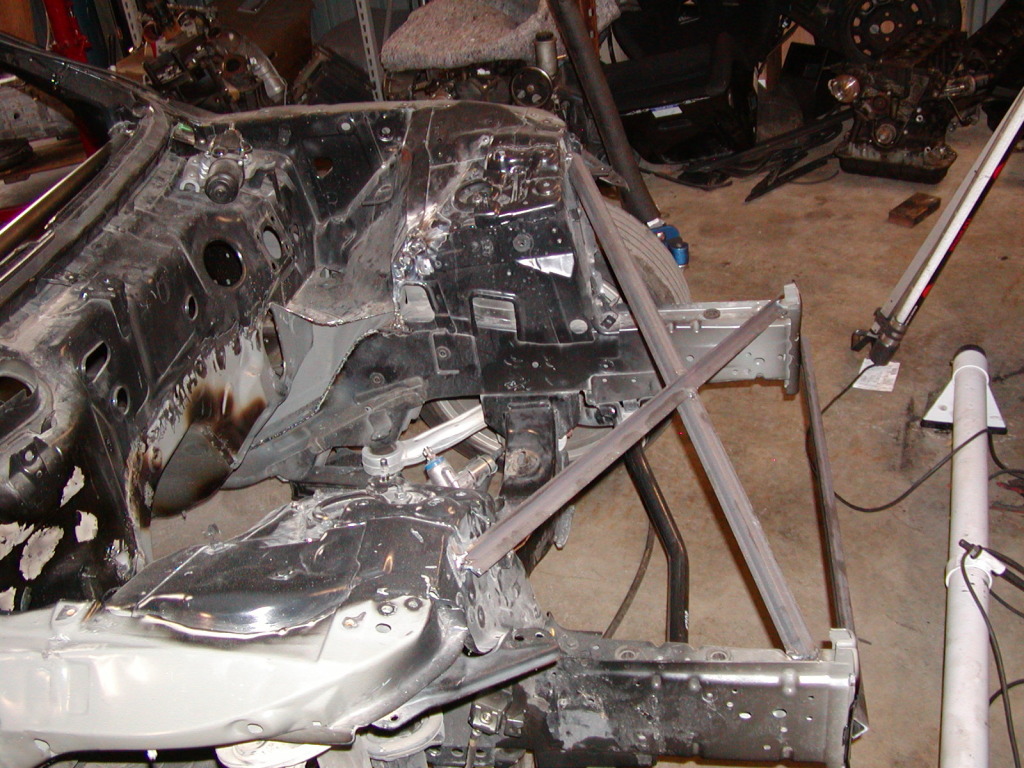

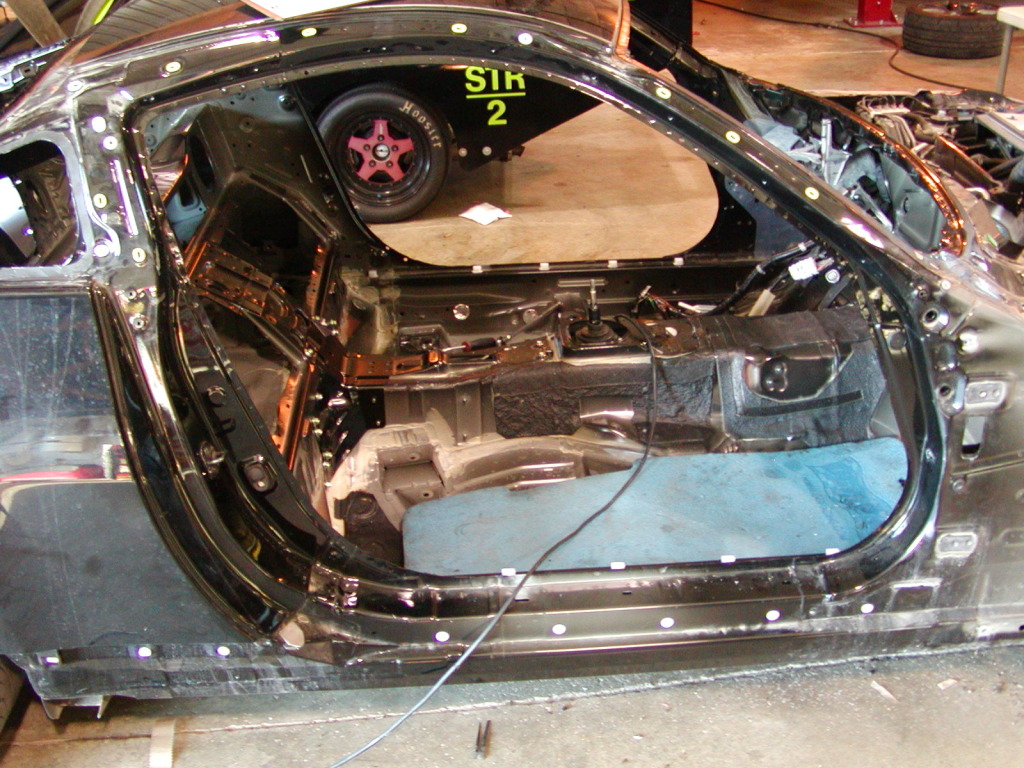

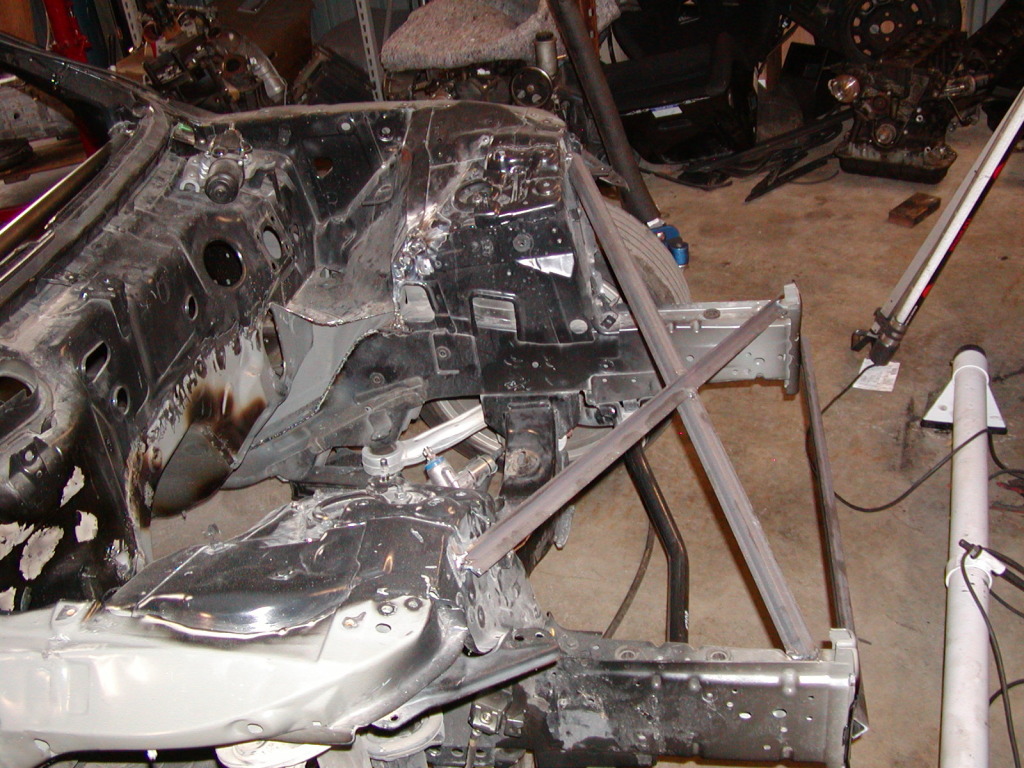

We started this project over a year ago, when a very totaled 2007 350Z showed up on a transporter. The front end of the car was pretty much caved in and there was unibody damage to the front frame rails. So we started the process of tearing down the car to a shell, so it could go to the frame shop and get squared back up.

We completely gutted the car from one end to the other, in preperation for the cage work to follow.

Ok I guess at little background information is in order. I have been in the Automotive industry for over 30 years and building race cars for 25 of that 30. Up to a few years ago, It was pretty much all dragracing cars, including working for Jerry Haas, building NHRA prostock and promod cars. My specialties include Chassis design, Roll cage design, fabrication and welding, suspension and brakes and track alignments. When I started at ET about 3 1/2 years ago, I started building road racing cars and this 350Z is by far the craziest car of this type I have ever built.

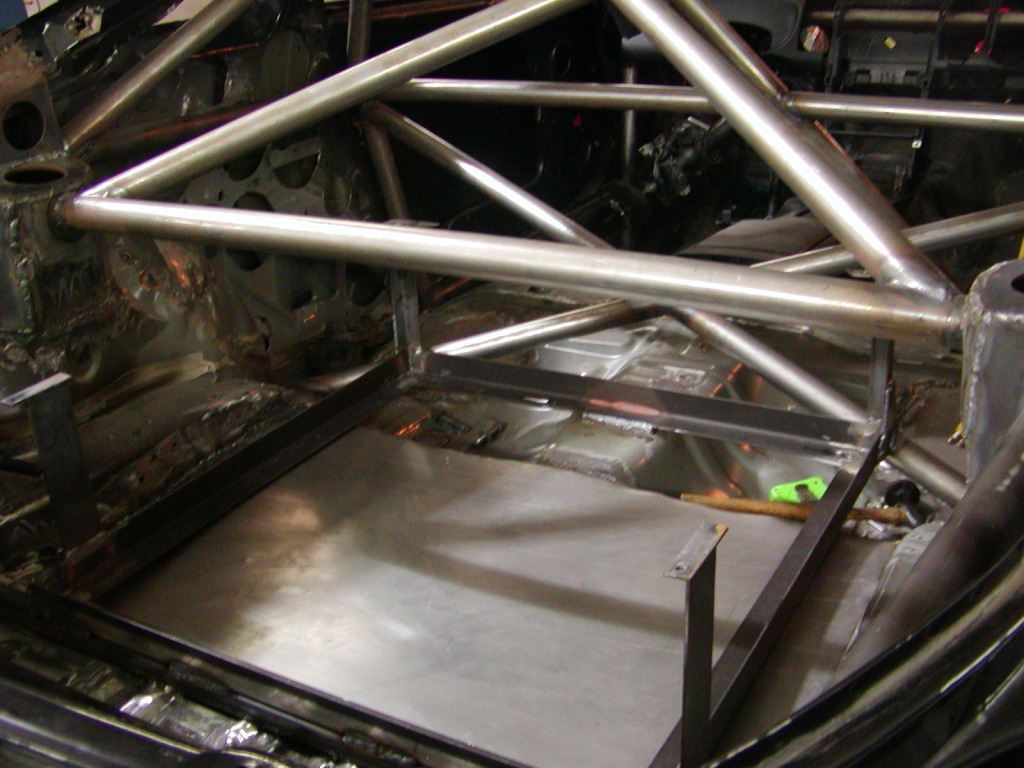

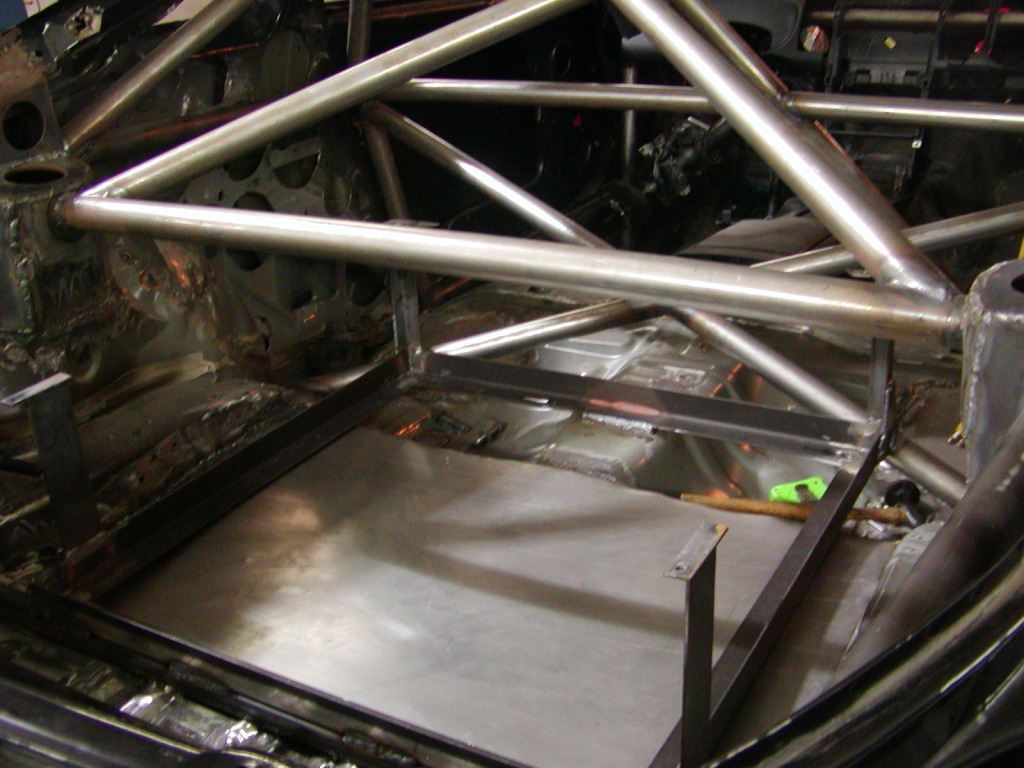

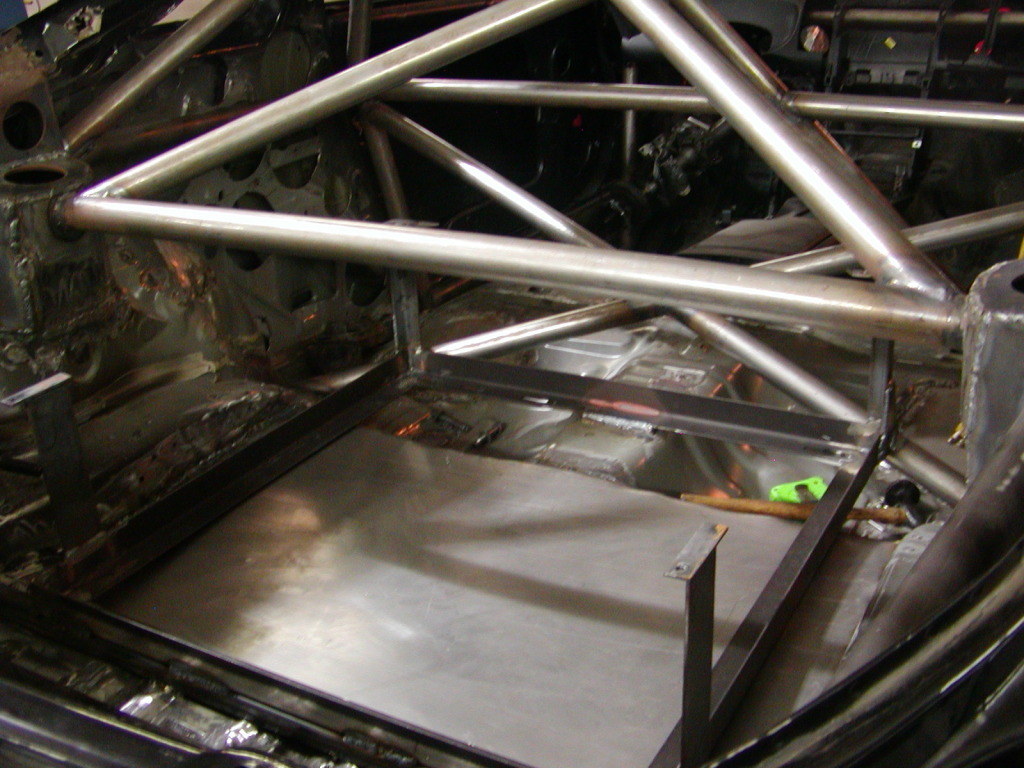

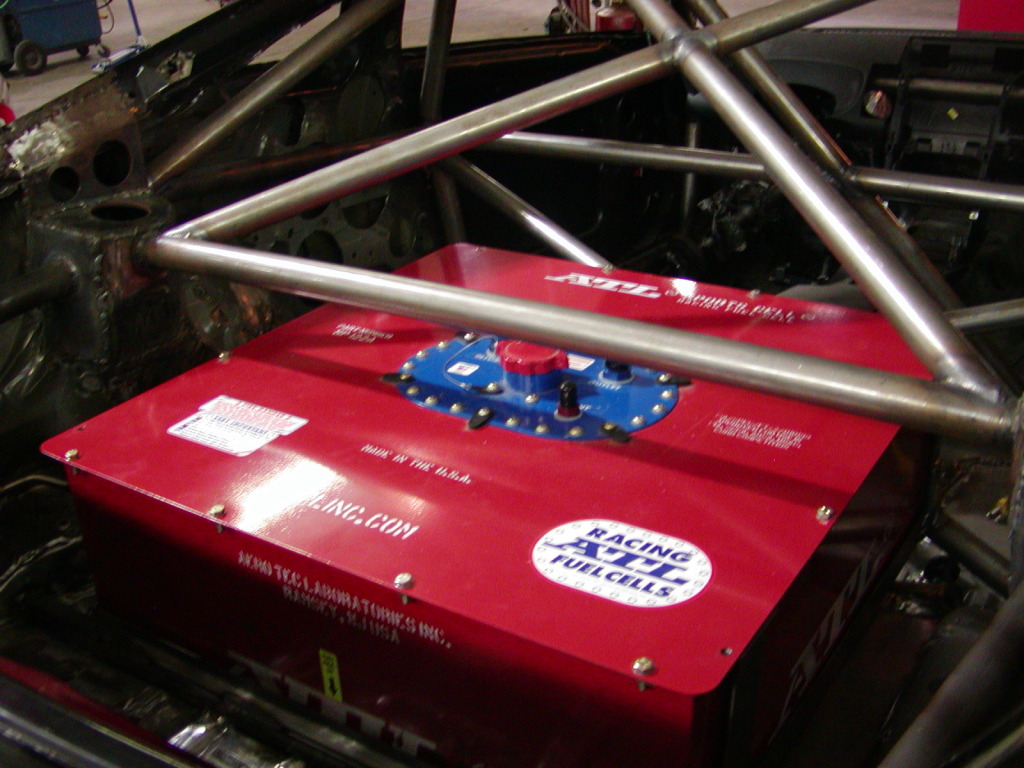

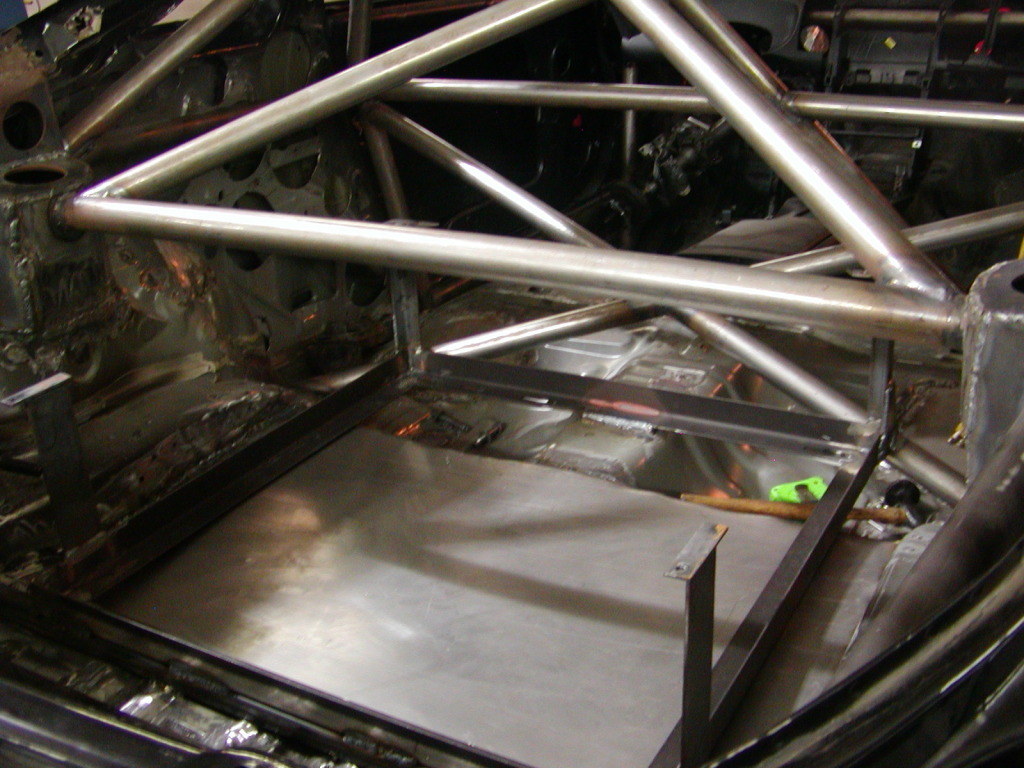

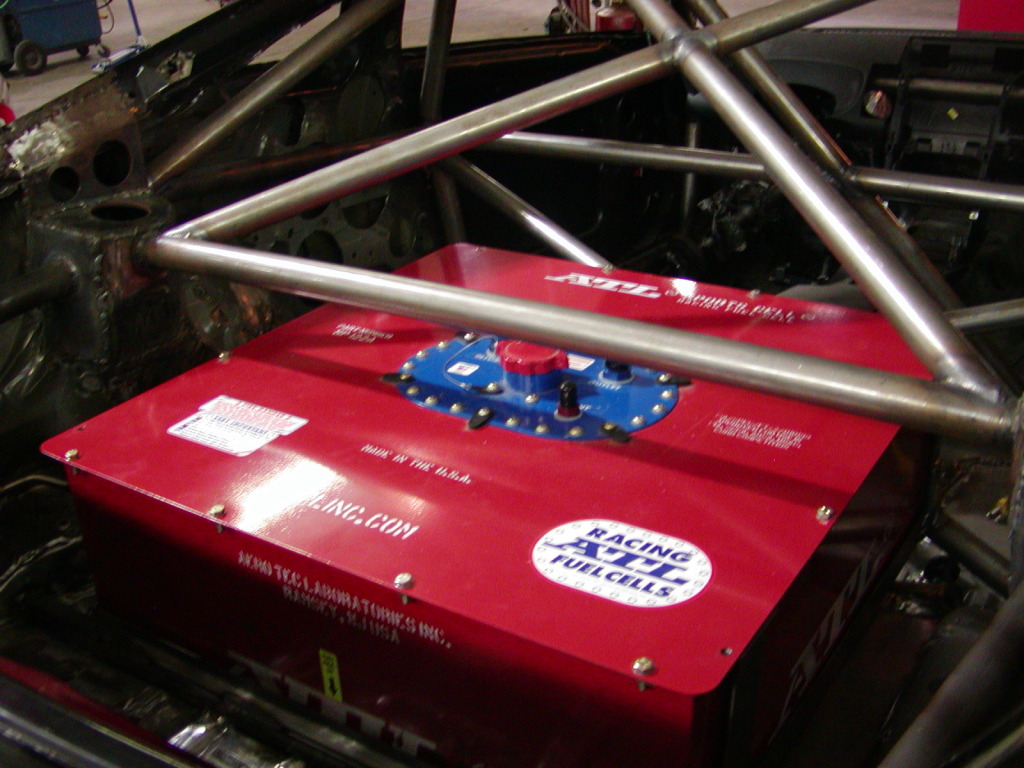

So moving on, As we started sorting out what drivetrain was going into the car, it became apparrent to me that I was going to have to build a chassis that would have to stand up to massive amounts of side loads as well as channel over a thousand horsepower to the rear wheels. After sharpening my pencil, lol, I set out to build a super strong chassis that would meet all those qualifications. You will see in the next set of pictures this cage is as involved as they get.

For weight rules I used 1.5 diameter .120 wall DOM tubing and the cage is completely tig welded together. You will notice in the pictures that the rocker bars are doubled and there is a double X brace in the back, one high and one low. You can also see the roof skin was cut off, one for ease of construction and two, its being replaced with carbon fiber.

Well I have to get ready for work, so looking forward to another 100+ degree day in the shop. I will be adding more to this thread in the coming days, in an attempt to bring the project up to date. Again im going to try and cover this bulid in sections and will be posting more this weekend.

To be continued.............................

So here goes:

We started this project over a year ago, when a very totaled 2007 350Z showed up on a transporter. The front end of the car was pretty much caved in and there was unibody damage to the front frame rails. So we started the process of tearing down the car to a shell, so it could go to the frame shop and get squared back up.

We completely gutted the car from one end to the other, in preperation for the cage work to follow.

Ok I guess at little background information is in order. I have been in the Automotive industry for over 30 years and building race cars for 25 of that 30. Up to a few years ago, It was pretty much all dragracing cars, including working for Jerry Haas, building NHRA prostock and promod cars. My specialties include Chassis design, Roll cage design, fabrication and welding, suspension and brakes and track alignments. When I started at ET about 3 1/2 years ago, I started building road racing cars and this 350Z is by far the craziest car of this type I have ever built.

So moving on, As we started sorting out what drivetrain was going into the car, it became apparrent to me that I was going to have to build a chassis that would have to stand up to massive amounts of side loads as well as channel over a thousand horsepower to the rear wheels. After sharpening my pencil, lol, I set out to build a super strong chassis that would meet all those qualifications. You will see in the next set of pictures this cage is as involved as they get.

For weight rules I used 1.5 diameter .120 wall DOM tubing and the cage is completely tig welded together. You will notice in the pictures that the rocker bars are doubled and there is a double X brace in the back, one high and one low. You can also see the roof skin was cut off, one for ease of construction and two, its being replaced with carbon fiber.

Well I have to get ready for work, so looking forward to another 100+ degree day in the shop. I will be adding more to this thread in the coming days, in an attempt to bring the project up to date. Again im going to try and cover this bulid in sections and will be posting more this weekend.

To be continued.............................

#30

Thanks to eveyone for the great responce, so far. I guess this is as good as anytime to go ahead and post the next chapter! So here goes.

Lets see, I kinda left off in the middle of the cage work so why dont I start with posting some more pics fo the cage, in its completed form.

You will notice that in the last 2 pics that there is no firewall, the factory firewall was removed and is now a flat sheet metal 2-piece, that is dzused on and can be removed for servicablity. I also had to modify the floor under the driverseat, to get the seat mount low enough in the car for driver comfort. You may have

also noticed all of the holes that were sawed out of the interior sheet metal, that was done for weight reduction, any weight that is above the drivers waist line affects the center of gravity, so the more you can remove the better.

That pretty much covers the roll cage, if anybody has any questions at all, please dont hesitate to ask.

Im going to take an informal poll, what would eveybody like me to cover next?

The choises are:

1) suspension

2) brakes

3) body kit

I will cover all of it in time, but you guys tell me what order we do this in! I'll give this a day or two to see what you guys want next and we will continue from there................

Lets see, I kinda left off in the middle of the cage work so why dont I start with posting some more pics fo the cage, in its completed form.

You will notice that in the last 2 pics that there is no firewall, the factory firewall was removed and is now a flat sheet metal 2-piece, that is dzused on and can be removed for servicablity. I also had to modify the floor under the driverseat, to get the seat mount low enough in the car for driver comfort. You may have

also noticed all of the holes that were sawed out of the interior sheet metal, that was done for weight reduction, any weight that is above the drivers waist line affects the center of gravity, so the more you can remove the better.

That pretty much covers the roll cage, if anybody has any questions at all, please dont hesitate to ask.

Im going to take an informal poll, what would eveybody like me to cover next?

The choises are:

1) suspension

2) brakes

3) body kit

I will cover all of it in time, but you guys tell me what order we do this in! I'll give this a day or two to see what you guys want next and we will continue from there................

The following users liked this post:

PeterPotatoes (01-11-2021)

#39

Once again, my appologies for the delay, I have been doing 12 hour days on this project in 100 degree heat and its really taking its toll on me.

Ok since I have taken so long to get back on here, Im going to cover the suspension and the brakes in this segment.

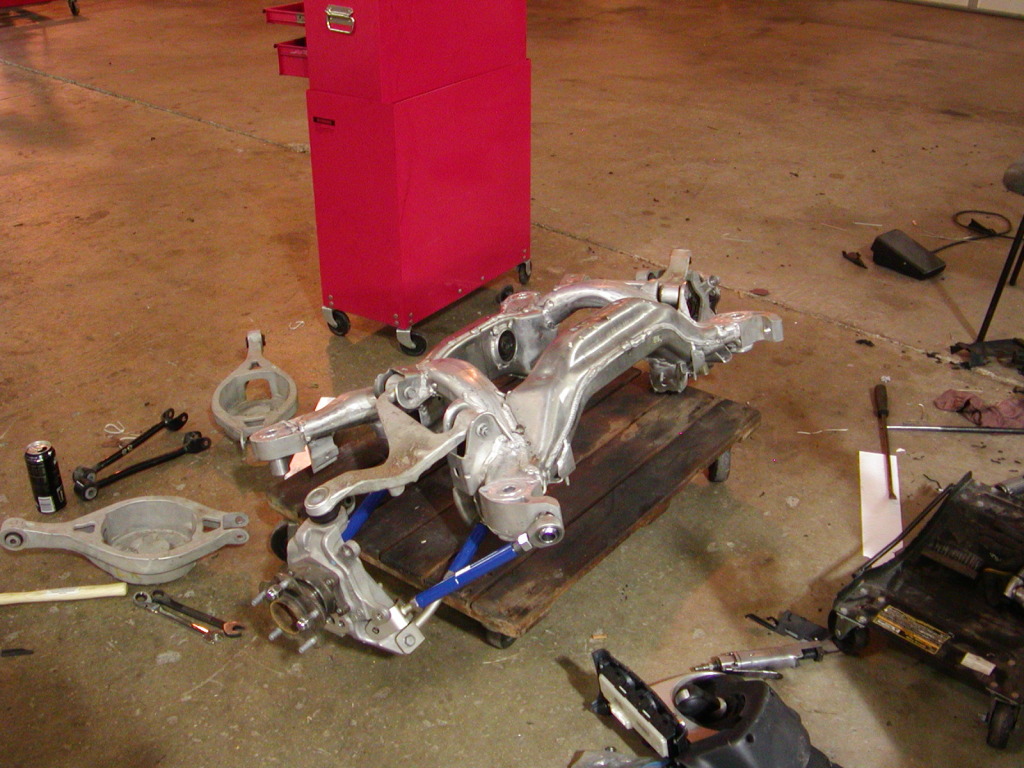

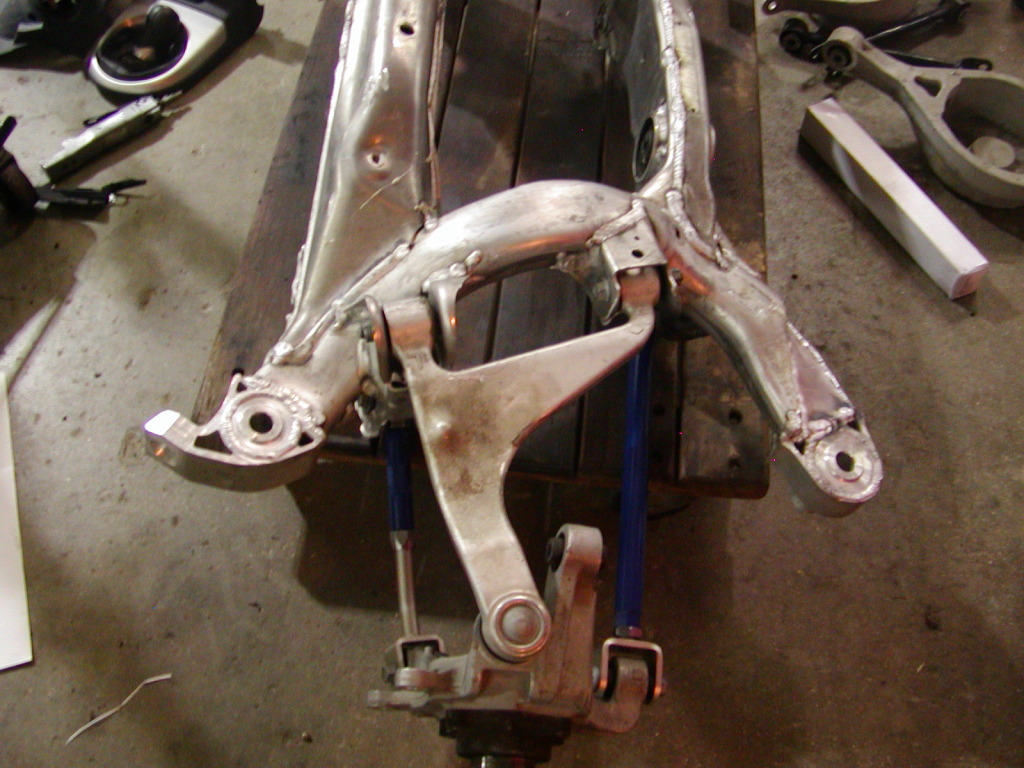

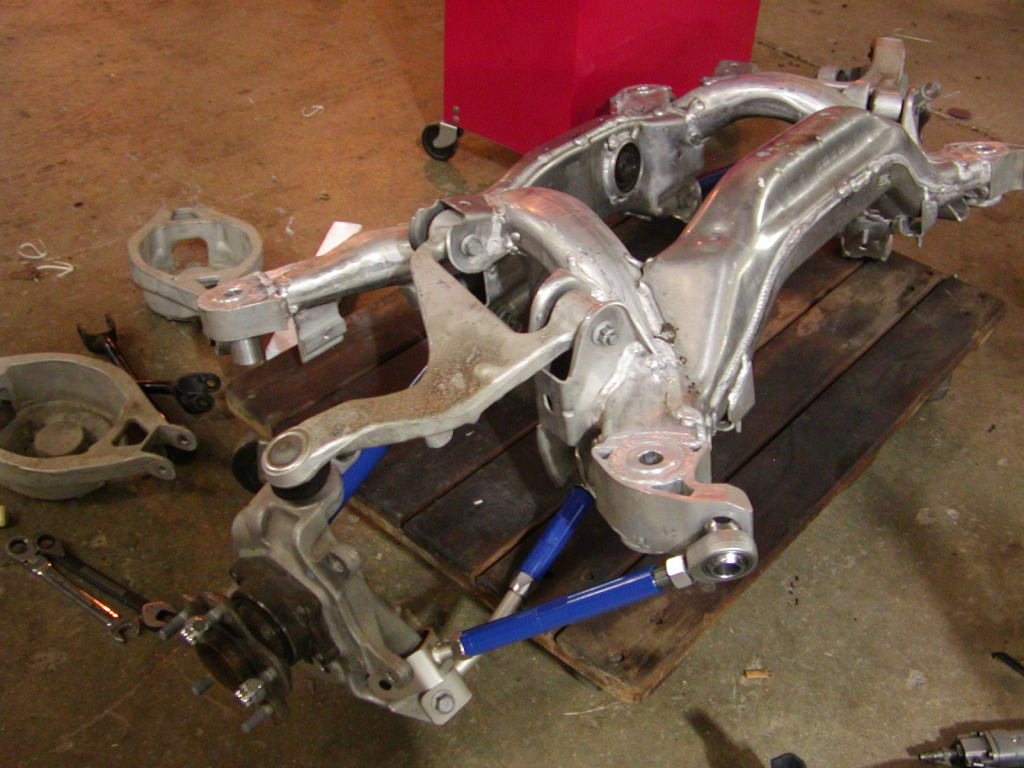

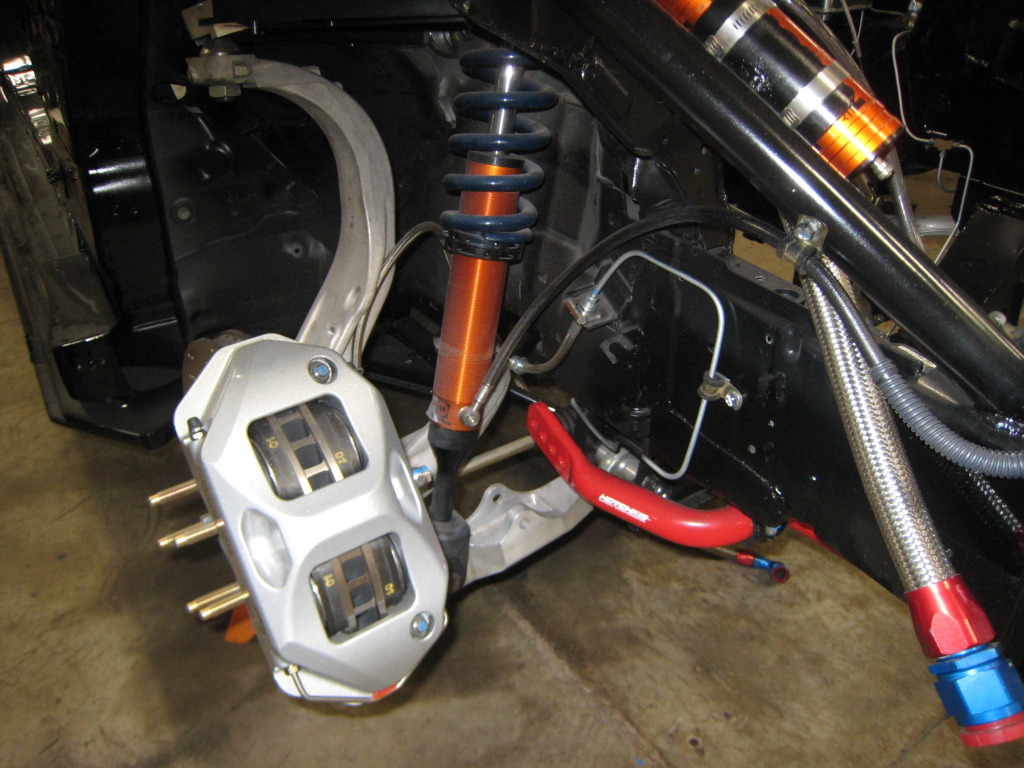

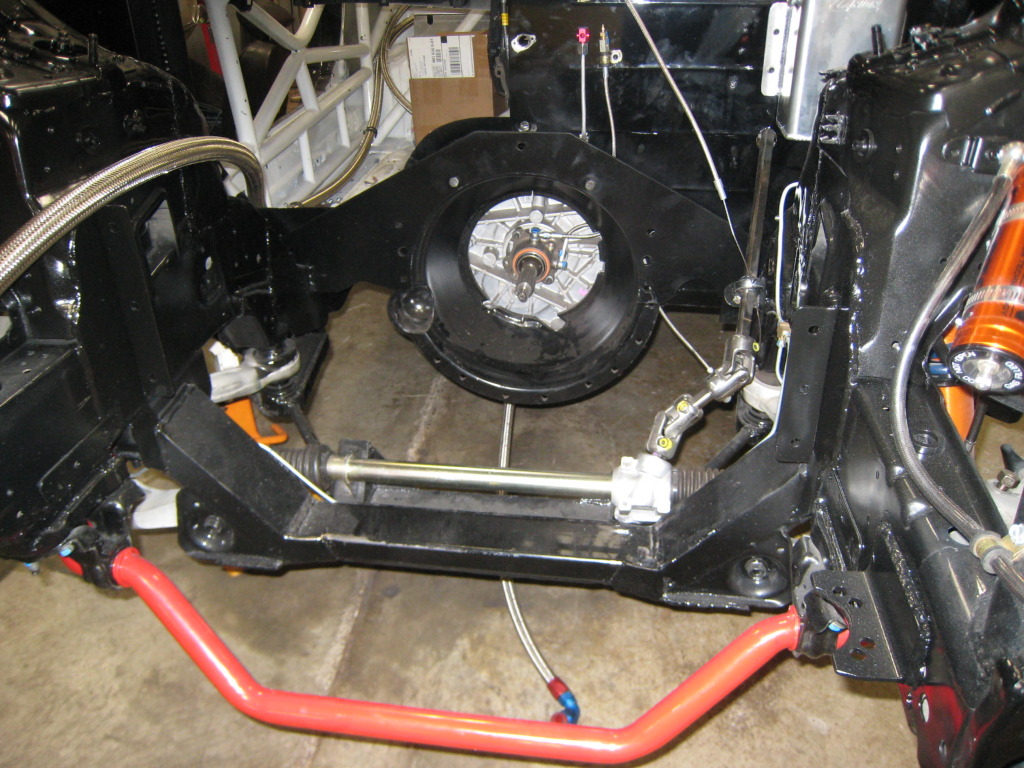

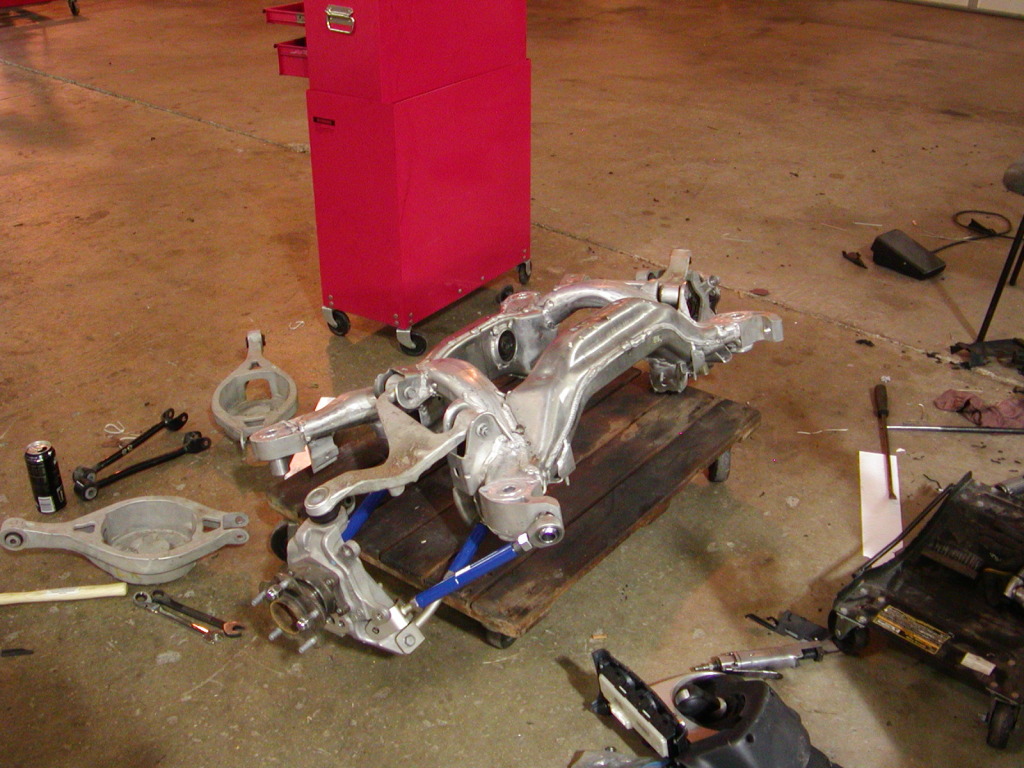

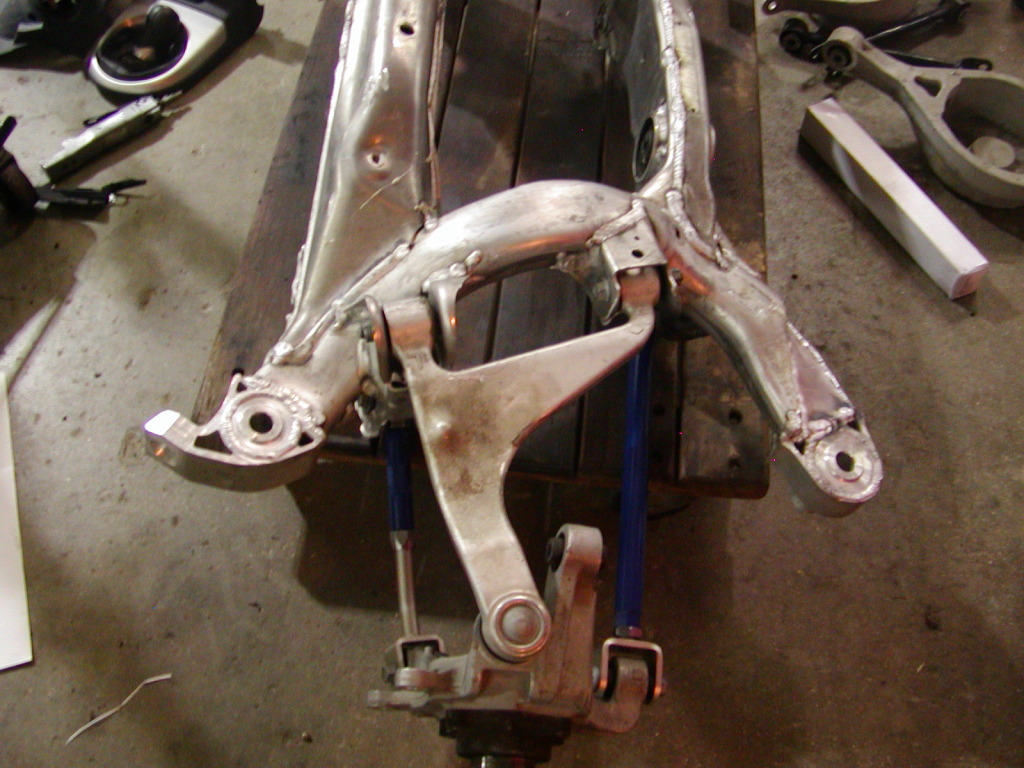

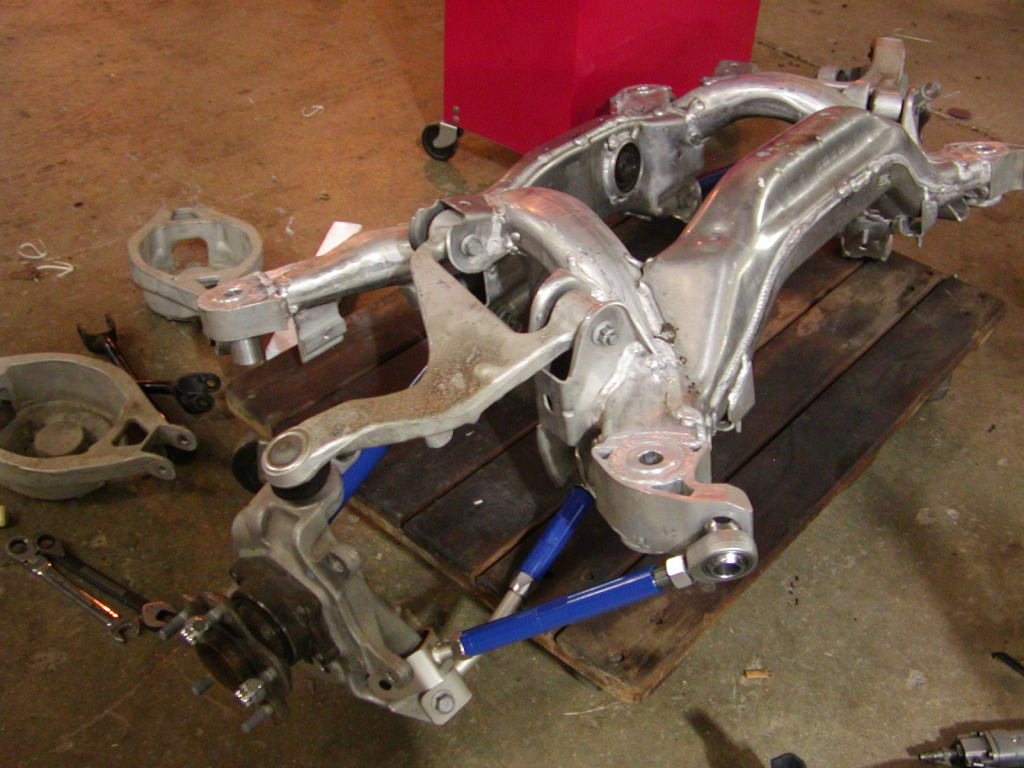

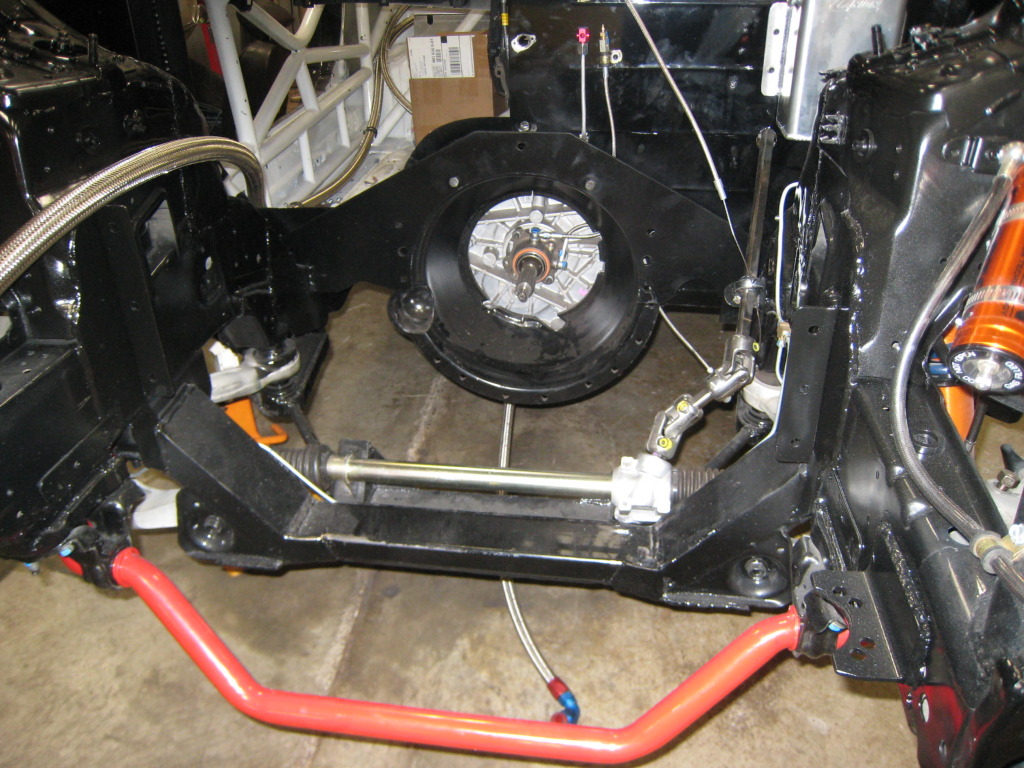

Ok starting with the suspension, this car has pretty much the best of everything on it, So we decided Moton struts were the best choise for this car, all of which have remote resivor's and of course are fully adjustable. before I post any pics, your going to notice a few things that are not factory(lol, not much is anymore) but what im refering to is the front crossmember that has been completely re-configured for reasons that will become obvious later. The rear subframe has also been highly modified and was actually cut down to lower the rear suspension and also the center of gravity. The rear trailing arms are from Megan racing and are all fully adjustable and we are using the largest sway bars we could find.

Maybe hard to tell, but the mounting points for the rear subframe were cut down and re-welded and all of the mounting bushings have been removed, so its hard mounted. While we not a 100% sure how long it will hold up we are using a Nismo rear diff and some super crazy aftermarket axles. Lets face it traction on this car is going to be an issue, remember this car is being set up for road course racing, so traction is definately a concern. Here are some pics of the complete and finished rear suspension.

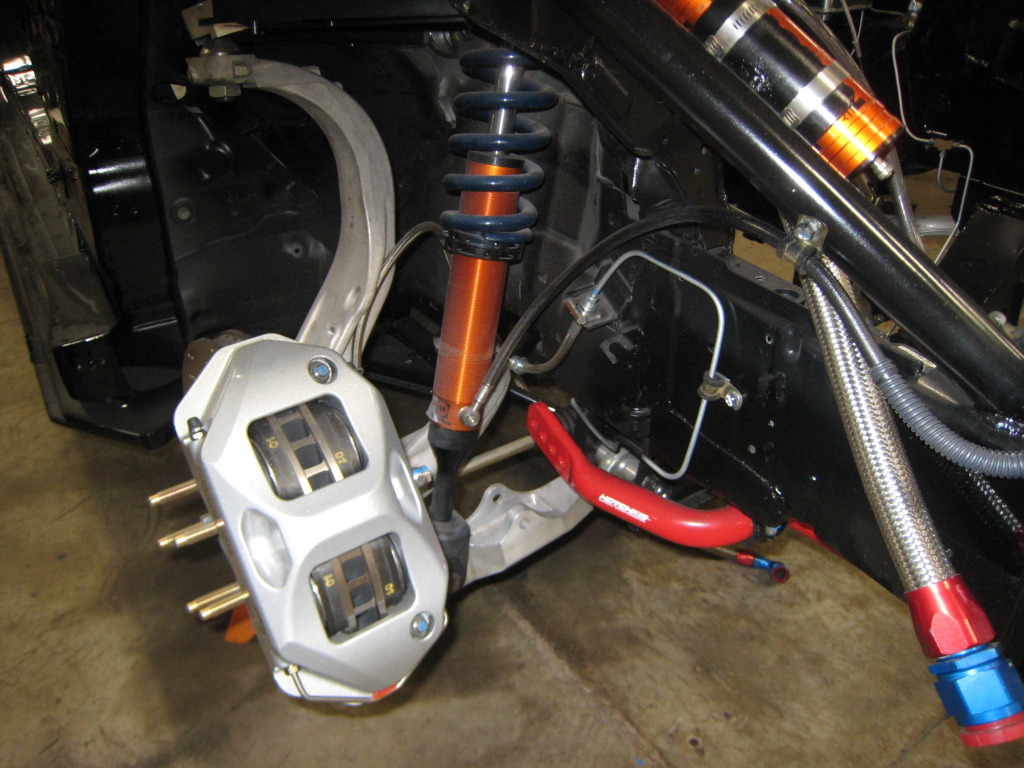

The front suspension uses only the stock spindles the upper and lower control arms are from Fontana racing(not the greatest company to deal with) but nice pieces anyway. All the bushings have been replaced with hiem's and again everything is massively adjustable.

The steering rack is a custom made piece we got from Unisteer and also uses hiems instead of tie rod ends.

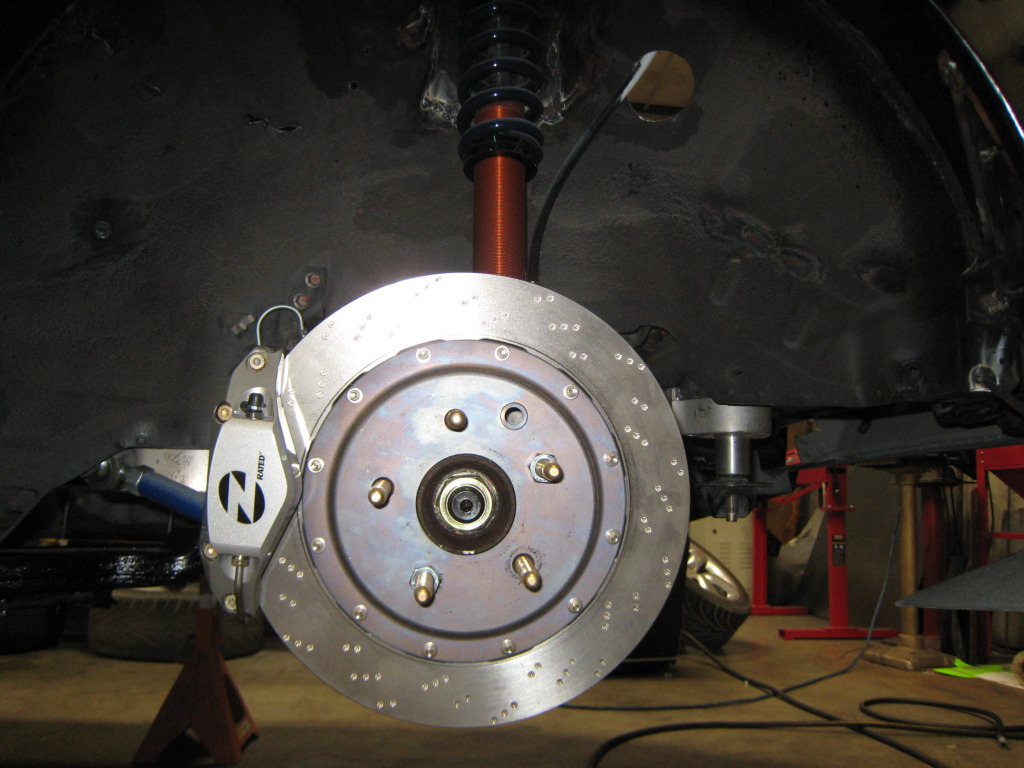

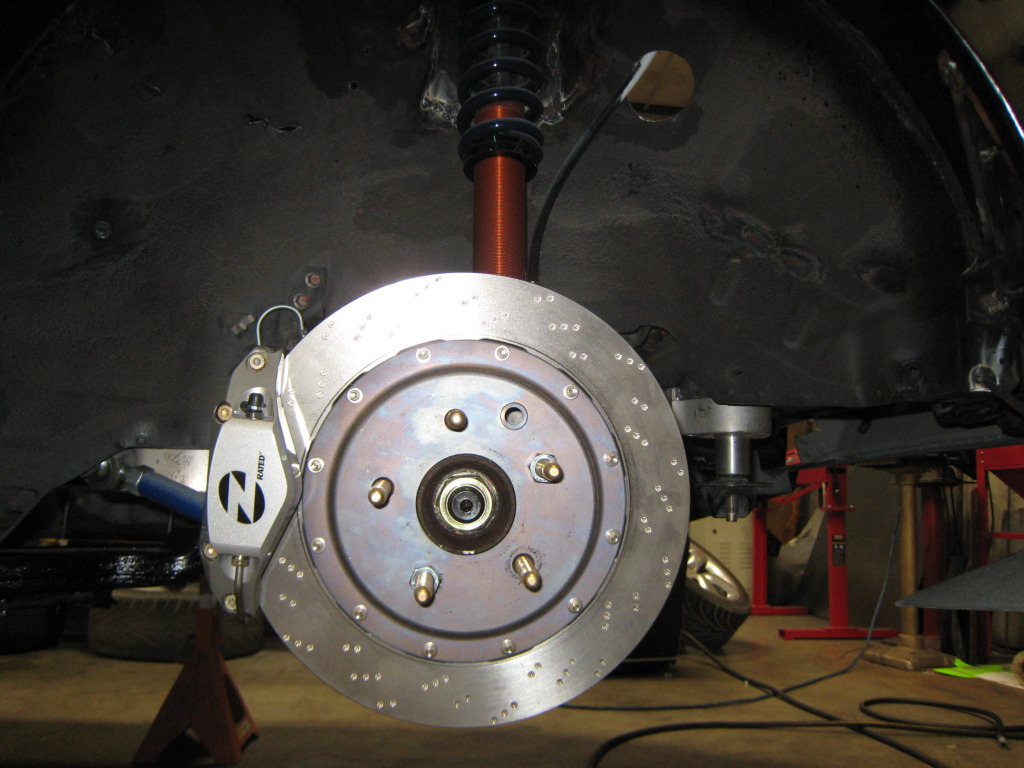

Next would be the brakes, we are using Performance Friction calipers, fully floating 14 in rotors in the front and 12 in in the rear, we are a performance friction dealer and can get any of the parts you see on here, for a pretty good price for anybody interseted. Of course we are using stainless braided hoses to get the fluid to the calipers. Another point worth mentioning, we have installed a Tilton pedal set with a fully adjustable bias control.

That should be plenty of brakes to haul this monster to a stop, just a side note, there are a bunch of different pad compounds made for these calipers, so they could be used for a street application. Lastly if there is something I havent covered or anybody has questions, PLEASE ASK!

Ok since I have taken so long to get back on here, Im going to cover the suspension and the brakes in this segment.

Ok starting with the suspension, this car has pretty much the best of everything on it, So we decided Moton struts were the best choise for this car, all of which have remote resivor's and of course are fully adjustable. before I post any pics, your going to notice a few things that are not factory(lol, not much is anymore) but what im refering to is the front crossmember that has been completely re-configured for reasons that will become obvious later. The rear subframe has also been highly modified and was actually cut down to lower the rear suspension and also the center of gravity. The rear trailing arms are from Megan racing and are all fully adjustable and we are using the largest sway bars we could find.

Maybe hard to tell, but the mounting points for the rear subframe were cut down and re-welded and all of the mounting bushings have been removed, so its hard mounted. While we not a 100% sure how long it will hold up we are using a Nismo rear diff and some super crazy aftermarket axles. Lets face it traction on this car is going to be an issue, remember this car is being set up for road course racing, so traction is definately a concern. Here are some pics of the complete and finished rear suspension.

The front suspension uses only the stock spindles the upper and lower control arms are from Fontana racing(not the greatest company to deal with) but nice pieces anyway. All the bushings have been replaced with hiem's and again everything is massively adjustable.

The steering rack is a custom made piece we got from Unisteer and also uses hiems instead of tie rod ends.

Next would be the brakes, we are using Performance Friction calipers, fully floating 14 in rotors in the front and 12 in in the rear, we are a performance friction dealer and can get any of the parts you see on here, for a pretty good price for anybody interseted. Of course we are using stainless braided hoses to get the fluid to the calipers. Another point worth mentioning, we have installed a Tilton pedal set with a fully adjustable bias control.

That should be plenty of brakes to haul this monster to a stop, just a side note, there are a bunch of different pad compounds made for these calipers, so they could be used for a street application. Lastly if there is something I havent covered or anybody has questions, PLEASE ASK!