DIY Replacing your belts. Very Easy

#1

Registered User

Thread Starter

Ok...this is an easy DIY maintenance item so save yourself some money and do it yourself.

Step one, get your car up on some ramps or if you like use jack stands to get even more lift. I just used ramps but here is some pictures from doing my own brakes.

The dealer or a mechanic with a real lift does not need to remove the under-tray completely but you probably will... like myself.

Here is the view with the under-tray removed.

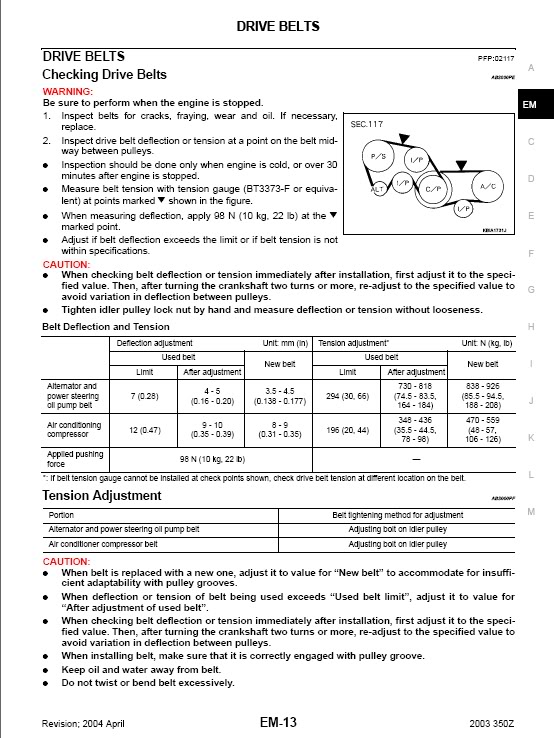

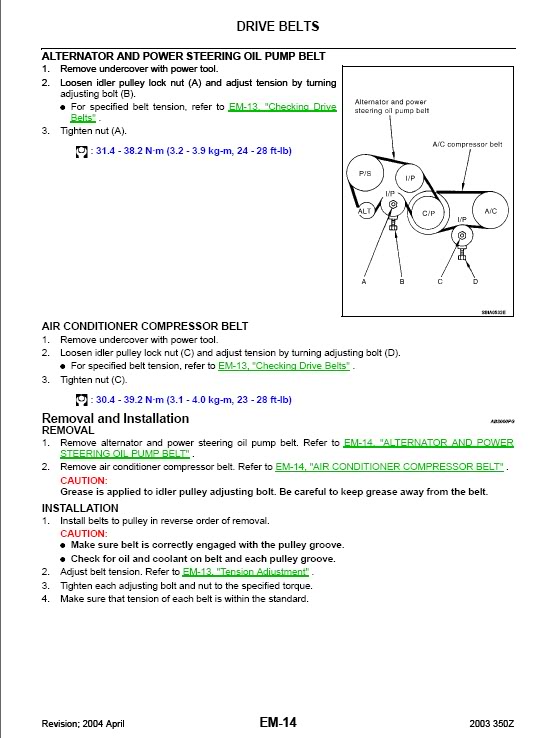

There are two belts. One runs the alternator and power steering oil pump, it is the wider of the two belts. The other narrower belt is for the A/C compressor. With a 14mm socket, I used a six point socket, loosen the idler pulley lock nut on each pulley. They will be tight.

Now loosen the adjuster adjuster bolts until the belts are free to remove.

Remove belts and install the new ones making sure the grooves are all seated properly.

Tighten the adjuster bolts until you have about 8-9mm of deflection on the smaller A/C belt with 22lbs of pressure and 4-5mm of deflection on the thicker belt. Then tighten the lock bolt torquing them to 26 ft-lb. Turn the engine over a few times to let the belts get uniform tension and recheck the belt tensions. When you are satisfied reinstall the under-tray.

Step one, get your car up on some ramps or if you like use jack stands to get even more lift. I just used ramps but here is some pictures from doing my own brakes.

The dealer or a mechanic with a real lift does not need to remove the under-tray completely but you probably will... like myself.

Here is the view with the under-tray removed.

There are two belts. One runs the alternator and power steering oil pump, it is the wider of the two belts. The other narrower belt is for the A/C compressor. With a 14mm socket, I used a six point socket, loosen the idler pulley lock nut on each pulley. They will be tight.

Now loosen the adjuster adjuster bolts until the belts are free to remove.

Remove belts and install the new ones making sure the grooves are all seated properly.

Tighten the adjuster bolts until you have about 8-9mm of deflection on the smaller A/C belt with 22lbs of pressure and 4-5mm of deflection on the thicker belt. Then tighten the lock bolt torquing them to 26 ft-lb. Turn the engine over a few times to let the belts get uniform tension and recheck the belt tensions. When you are satisfied reinstall the under-tray.

The following users liked this post:

terrj (06-12-2016)

#3

Registered User

Thread Starter

Thanks.

I am no real mechanic so you won't see me posting DIY's about replacing your clutch or upgrading your cams but luckily those types of threads are already posted. I also have not done many mods to write about though the Nismo suspension system is really starting to tempt me. I am just waiting until my shocks are shot before making a final decision. What can I say, I am a tight-wad I have been a teacher for 12 years now and I also love my car, so I want to share what info I can because the teaching thing is in my blood. So after years of mostly lurking I have been able to share a Brembo maintenance thread and now a replacing belts thread.

I have been a teacher for 12 years now and I also love my car, so I want to share what info I can because the teaching thing is in my blood. So after years of mostly lurking I have been able to share a Brembo maintenance thread and now a replacing belts thread.

I am no real mechanic so you won't see me posting DIY's about replacing your clutch or upgrading your cams but luckily those types of threads are already posted. I also have not done many mods to write about though the Nismo suspension system is really starting to tempt me. I am just waiting until my shocks are shot before making a final decision. What can I say, I am a tight-wad

I have been a teacher for 12 years now and I also love my car, so I want to share what info I can because the teaching thing is in my blood. So after years of mostly lurking I have been able to share a Brembo maintenance thread and now a replacing belts thread.

I have been a teacher for 12 years now and I also love my car, so I want to share what info I can because the teaching thing is in my blood. So after years of mostly lurking I have been able to share a Brembo maintenance thread and now a replacing belts thread.

Last edited by dothemath; 02-03-2008 at 07:28 PM.

#7

Registered User

Thread Starter

If you don't have an electric drill for all of the screws holding on the plastic under-tray that will be what takes you the most time. There is definitely no reason to pay a mechanic to do this job unless you just have absolutely no mechanic skill at all. I am sure if you over tighten the belts way too much you could cause some kind of problem but no one here would do that

Trending Topics

#12

Retired Admin

iTrader: (95)

What exactly is "deflection" vs "tension?" I was under the impression that deflection meant how much the belt was willing to give when you put force (i.e., press down with finger) and tension was how much force it was required to move it (i.e., the force required to lift the belt).

When I did my belts, I did what I thought was right, regarding deflection. So, when I pressed down on it, I made sure both belts can be pressed down the appropriate measurements. This only resulted in squealing sounds coming from the belts for the first 2 minutes upon turning over the engine.

The issue was resolved after tightening both belts until they were both tightly stretched on the pulleys.

BTW, go to the Nissan dealership and ask for the alternator belt and the a/c belt. The total was about $40 before tax.

When I did my belts, I did what I thought was right, regarding deflection. So, when I pressed down on it, I made sure both belts can be pressed down the appropriate measurements. This only resulted in squealing sounds coming from the belts for the first 2 minutes upon turning over the engine.

The issue was resolved after tightening both belts until they were both tightly stretched on the pulleys.

BTW, go to the Nissan dealership and ask for the alternator belt and the a/c belt. The total was about $40 before tax.

#13

Registered User

Thread Starter

I don't have the part numbers any more. I just bought the belts at the dealer.

I need re-word that second line and it should say recheck the deflection...sorry. There is a tool to check the belt deflection, but as my mechanic told me..."I will know when they are tight enough". I only experienced a very light chirp the first time I started the engine and so I just tightened the belts a little more.

I need re-word that second line and it should say recheck the deflection...sorry. There is a tool to check the belt deflection, but as my mechanic told me..."I will know when they are tight enough". I only experienced a very light chirp the first time I started the engine and so I just tightened the belts a little more.

#16

Registered User

Thread Starter

You probably don't have the belts tight enough. A month after installing mine it got really cold...for north Florida...and they squealed a bit at start up. Once I adjusted the belts a little bit they have been fine.

#18

Retired Admin

iTrader: (95)

Originally Posted by NA&CH

Minus the undertray this is a tops 25min job.

Thanks for the write up guys

One questions. I did get a loud squeel twice 35mins after I finished. COuld something be to tight??

Thanks again

Chris

Thanks for the write up guys

One questions. I did get a loud squeel twice 35mins after I finished. COuld something be to tight??

Thanks again

Chris

#19

Thanks for the post guys.

I tightened them to as close to the deflection I could without a tool. I used a mm ruler and pushed down. I should have checked the belts tension before removing them. I will tighten them again a few turns. Is there a tool I can buy or rent to get it on the money or closer then my DIY'er way

and pushed down. I should have checked the belts tension before removing them. I will tighten them again a few turns. Is there a tool I can buy or rent to get it on the money or closer then my DIY'er way

Chris

I tightened them to as close to the deflection I could without a tool. I used a mm ruler

and pushed down. I should have checked the belts tension before removing them. I will tighten them again a few turns. Is there a tool I can buy or rent to get it on the money or closer then my DIY'er way

and pushed down. I should have checked the belts tension before removing them. I will tighten them again a few turns. Is there a tool I can buy or rent to get it on the money or closer then my DIY'er way

Chris

#20

Retired Admin

iTrader: (95)

The applied pushing force is 22lbs. So, put 22lbs of pressure and then measure. I used the handle of my hammer to press down and put weight (20lbs + hammer weight + little bit of me holding it all = ~22lbs) on top of the hammer to apply the said force. I got somebody else to measure while I held the weight. It's ghetto, but it works.