Procharger - Anyone running 12PSI without breaking belts?

#23

Registered User

iTrader: (8)

Join Date: Feb 2003

Location: San Antonio, Texas

Posts: 1,248

Likes: 0

Received 0 Likes

on

0 Posts

okay....haven't been on the boards for minute. Just saw this post. I posted the same problems jay was having and same problems you are having. I never had a problem with belts breaking with the 9psi setup. But the minute we put the 12psi setup with he AAM brace...all hell broke loose. I read the threads; got some advice from Jay (Go TT, or tighnen belts and stick with gates) called Jason Industrial ref. jason tiger belts, they told me to stick with the gates belts because the gates material was better and dont waste my money on their belts.....wow.. so back to square one.

First time the belts broke, seems the tension was too loose (used the same belts with the 9psi set up) may have been worn anyway. I bought 4 belts from procharger, tuner put them on again, put the car on the dyno had couple of runs, then noticed that the front belt was riding too high toward the housing suggesting alignment was off. Since there were no belt or alignment issues prior to the AAM Brace install, that could be a cause for the alignment being off. We took the AAM brace off. The alignment was back to being straight and belts were aligned properly; but damage had already been done from stress of improper alignment, weakning the strength of the belts from prior pulls. After a couple of more pulls tuning the car, the belts popped again. We put back on the last set of belts, with proper tight tension, car tuned for 12psi, I opted not to continue and risk popping my last set of belts. Even though it took us taking off the AAM Brace, proper tension, I said enough was enough. The car runs good, pulls hard with 12psi setup, gate belts are holding up, I just didn't want to chance it again on the dyno. My take....make sure the belts are tight, during the rev, look at the belts to see if they are riding too high or low, take off the AAM Brace, that may be the source of the alignment problem. It seemed to clear up my alignment issue. Nothing is perfect.

First time the belts broke, seems the tension was too loose (used the same belts with the 9psi set up) may have been worn anyway. I bought 4 belts from procharger, tuner put them on again, put the car on the dyno had couple of runs, then noticed that the front belt was riding too high toward the housing suggesting alignment was off. Since there were no belt or alignment issues prior to the AAM Brace install, that could be a cause for the alignment being off. We took the AAM brace off. The alignment was back to being straight and belts were aligned properly; but damage had already been done from stress of improper alignment, weakning the strength of the belts from prior pulls. After a couple of more pulls tuning the car, the belts popped again. We put back on the last set of belts, with proper tight tension, car tuned for 12psi, I opted not to continue and risk popping my last set of belts. Even though it took us taking off the AAM Brace, proper tension, I said enough was enough. The car runs good, pulls hard with 12psi setup, gate belts are holding up, I just didn't want to chance it again on the dyno. My take....make sure the belts are tight, during the rev, look at the belts to see if they are riding too high or low, take off the AAM Brace, that may be the source of the alignment problem. It seemed to clear up my alignment issue. Nothing is perfect.

Last edited by SILKZ03; 05-13-2009 at 12:09 PM.

#24

Registered User

Join Date: Jun 2008

Location: Oakland (Deep Creek), Maryland

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Well not to confuse things but I actually had significant belt wear and tearing before I got the AAM flexbrace. After I got it, the belts have been fine. But again, I am only using the 9 lbs. pulley. I guess my belts could have been mis-aligned before the brace install, then better aligned afterward. But I guess the bottom-line is that accurate alignment is critical and only gets more so the higher the boost due to the increased pulley speeds involved.

#26

Registered User

Thread Starter

iTrader: (5)

Join Date: Nov 2008

Location: Shreveport, Louisiana

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

Thats what I was thinking. The whole kit has way too much flex in it. Why not make a one off out of a stronger material AND brace it from pulling in on itself. It seems like even with the AAM Flex brace, that it still flexes way too much.

#32

Registered User

iTrader: (8)

Join Date: Feb 2003

Location: San Antonio, Texas

Posts: 1,248

Likes: 0

Received 0 Likes

on

0 Posts

Well not to confuse things but I actually had significant belt wear and tearing before I got the AAM flexbrace. After I got it, the belts have been fine. But again, I am only using the 9 lbs. pulley. I guess my belts could have been mis-aligned before the brace install, then better aligned afterward. But I guess the bottom-line is that accurate alignment is critical and only gets more so the higher the boost due to the increased pulley speeds involved.

Hey Jay, whats good! still taking care of soldiers brah!

Last edited by SILKZ03; 05-13-2009 at 10:28 PM.

#34

Registered User

Thread Starter

iTrader: (5)

Join Date: Nov 2008

Location: Shreveport, Louisiana

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

Its a hit and miss type of thing I guess. At the 9psi set up I never had any belt wear or problems with aligment before the brace. After the brace, something just didn't seem right after the install. Seemed to be binding some kind of way. Which suggested could be the brace because that was the only thing done differently. Put the 12psi set on....then all hell broke loose. After so many pulls and belts breaking, decided pull it off, Now, alls G. Dunno bro...

Hey Jay, whats good! still taking care of soldiers brah!

Hey Jay, whats good! still taking care of soldiers brah!

Sorry for such a noob question!

#35

da Terminator!

iTrader: (62)

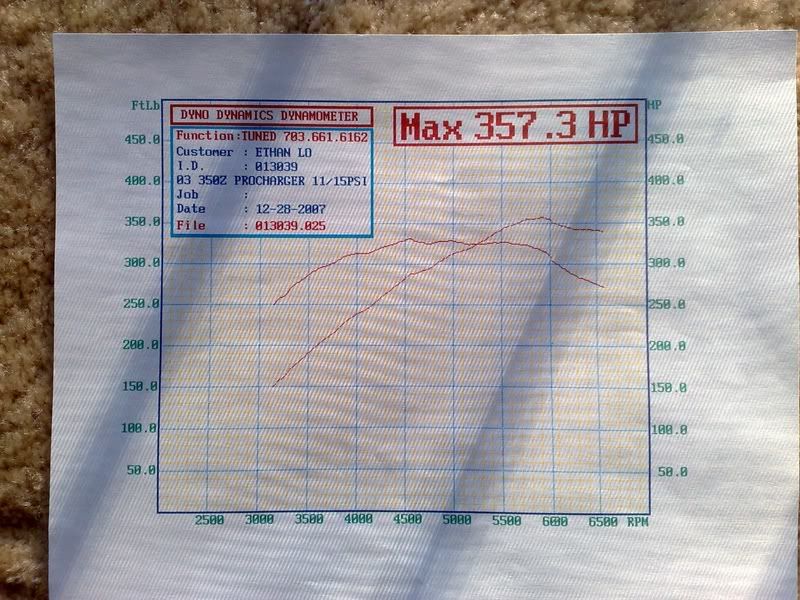

lol guess I'm not the only person with belt issue! I'm running a 15psi pulley, AAM brace and it seems to be holding out fine. Without the brace, my car was breaking belts on the freaking dyno during tuning. Frank Hills actually designed the AAM brace and it really helped eliminating a lot of the issues. See my sig!

#36

Registered User

Thread Starter

iTrader: (5)

Join Date: Nov 2008

Location: Shreveport, Louisiana

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

lol guess I'm not the only person with belt issue! I'm running a 15psi pulley, AAM brace and it seems to be holding out fine. Without the brace, my car was breaking belts on the freaking dyno during tuning. Frank Hills actually designed the AAM brace and it really helped eliminating a lot of the issues. See my sig!

#38

Registered User

iTrader: (8)

Join Date: Feb 2003

Location: San Antonio, Texas

Posts: 1,248

Likes: 0

Received 0 Likes

on

0 Posts

With the 12psi I hit 370whp easily and quickly at 5,000, with 336 torque, the problem is once the power starts climbing to the 400 mark the belts break...and there is where we stopped trying. According to the graphs and tuner I jumped 60hp with comparison to the 9psi set up. But too many pulls too many belts breaking and stress on the engine...I told them no more. I have a great tune were it is right now and happy with it. The belts dont break, the power is incredibly different and instantaneously then the 9psi set up. My neck finally jerks back and pinned to the seat, I didn't feel that with the 9psi. Oh by the way, my car is automatic...I lost 15 - 20% hp on the dyno from the go. Yesterday, I had a chance to play and test it out for the first time. While heading home from work on the freeway....a GTO tested me...lets just say the 12psi set up ain't no joke....he got dusted. I had to slow up for him to catch up then I get thumbs up and a WTF you got in there

. For you automatic guys out there....High stall Torque coverter and valvebody is highly recommended. Im not an advocate for racing believe me but sometimes you gotta do what you gotta do especially to see where you money is going. 12psi is worth it

. For you automatic guys out there....High stall Torque coverter and valvebody is highly recommended. Im not an advocate for racing believe me but sometimes you gotta do what you gotta do especially to see where you money is going. 12psi is worth it

Last edited by SILKZ03; 05-15-2009 at 12:10 AM.

#39

Registered User

Thread Starter

iTrader: (5)

Join Date: Nov 2008

Location: Shreveport, Louisiana

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

From what I was told the brace is needed for anything above 12-14psi. My belts were breakin with it. oh, and I still have the 9psi set up. According to my tuner, during the pull the 9psi was actually was puttin out 11psi, you can imagine what the 12psi set up was actually putting out...thus breaking the belts. Bottoline, I wanted to hit the 400 mark by buying the 12psi set up. According to my tuner the engine is putting out well over 400 but the belts break before it hits the mark. With the 9psi I was making 370whp at around 6,000 rpm, all said and done 381whp and 310 torque.

With the 12psi I hit 370whp easily and quickly at 5,000, with 336 torque, the problem is once the power starts climbing to the 400 mark the belts break...and there is where we stopped trying. According to the graphs and tuner I jumped 60hp with comparison to the 9psi set up. But too many pulls too many belts breaking and stress on the engine...I told them no more. I have a great tune were it is right now and happy with it. The belts dont break, the power is incredibly different and instantaneously then the 9psi set up. My neck finally jerks back and pinned to the seat, I didn't feel that with the 9psi. Oh by the way, my car is automatic...I lost 15 - 20% hp on the dyno from the go. Yesterday, I had a chance to play and test it out for the first time. While heading home from work on the freeway....a GTO tested me...lets just say the 12psi set up ain't no joke....he got dusted. I had to slow up for him to catch up then I get thumbs up and a WTF you got in there . For you automatic guys our there....High stall Torque coverter and valvebody. Im not an advocate for racing beleive me but sometimes you gotta do what you gotta do especially to see where you money is going. 12psi is worth it

. For you automatic guys our there....High stall Torque coverter and valvebody. Im not an advocate for racing beleive me but sometimes you gotta do what you gotta do especially to see where you money is going. 12psi is worth it

With the 12psi I hit 370whp easily and quickly at 5,000, with 336 torque, the problem is once the power starts climbing to the 400 mark the belts break...and there is where we stopped trying. According to the graphs and tuner I jumped 60hp with comparison to the 9psi set up. But too many pulls too many belts breaking and stress on the engine...I told them no more. I have a great tune were it is right now and happy with it. The belts dont break, the power is incredibly different and instantaneously then the 9psi set up. My neck finally jerks back and pinned to the seat, I didn't feel that with the 9psi. Oh by the way, my car is automatic...I lost 15 - 20% hp on the dyno from the go. Yesterday, I had a chance to play and test it out for the first time. While heading home from work on the freeway....a GTO tested me...lets just say the 12psi set up ain't no joke....he got dusted. I had to slow up for him to catch up then I get thumbs up and a WTF you got in there

. For you automatic guys our there....High stall Torque coverter and valvebody. Im not an advocate for racing beleive me but sometimes you gotta do what you gotta do especially to see where you money is going. 12psi is worth it

. For you automatic guys our there....High stall Torque coverter and valvebody. Im not an advocate for racing beleive me but sometimes you gotta do what you gotta do especially to see where you money is going. 12psi is worth it

#40

Registered User

iTrader: (8)

Join Date: Feb 2003

Location: San Antonio, Texas

Posts: 1,248

Likes: 0

Received 0 Likes

on

0 Posts

Engine: 550cc inj, cosworth plenum, aam fuel return, headers, invidia exhaust, utec, test pipes, tranny and oil cooler, high stall torque converter, valvebody upgrade, throttle body, Denso plugs, technosquare reflash, walbro. Pretty much it.....thats revelant to your question. I never planned to build internals, just hit the 400whp mark thats it. You on the other hand have the build to do what you need to do good luck dawg!!

Last edited by SILKZ03; 05-15-2009 at 12:11 AM.