omg building an engine tech!!!!

#1

First of all im starting this thread for information, since it seems only a few people in the community understand things, hopefully we can add to this or make more threads similar. Going to try and keep this to just the engine block itself however. I am not claiming to be the most knowledgeable, but i know a bit and its a start. Just by reading this does not mean you can build an engine, but its a start and expect to build a couple normal engines to get a feel for it before trying anything high powered. This is also general for any engine not just the vq.

First of all the block itself, pretty simple stuff number of main bolts.

Early engines simply had two bolts per main like this.

This is perfectly acceptable, however not the greatest, not much uses this design anymore. Reasoning is that a four bolt main cap better distributes even load on the block to hold the crank in. It is not so that the crank be be torqued down tighter this is bad and more on it later on. Pic of a four bolt main in case no one has seen the vq. lol

Some engines such as General Motors ls/lq motors use 6 bolt mains, this does essentially the same thing as installing a girdle on a 2 or four bolt main engine with a girdle. (The thing that holds the crank in on the above picture although there are main caps under it.) It better distributes the load evenly across all the mains, this is an example of four bolt chevy engine without a girdle. As you can see nothing connects the main caps, the vq is the same way with the caps underneath the girdle.

This is a ls1 engine, as you can see there are holes on the side of the block where the main caps are, this causes the block to act as a girdle.

"So why is it important for everything to be even?" Great question, the answer is vibration and movement. If one cylinder produces 100 ft. lbs. of torque and another produces 80 ft. lbs. of torque then the force on the crank will be uneven. This can cause dangerous vibrations that can shatter engine parts, if its severe. Also the uneven pressure and vibrations can cause the crank to move forwards or back also known as "crank walk", ask the dsm guys about this one =P. As you can imagine something traveling at high rotational speeds and suddenly moving forwards and back can cause very sensational results, if your watching. If you own the car it will cause sensational tears. Harmonic balancer's are a part of this as well, some are weighted some are not, it varys by engine however they all have elastometers(sp?) or are liquid filled. This allows vibrations in the crank to travel into the balancer and be absorbed, instead of bouncing around inside the metal and causing bad things to happen. Flywheels are also sometimes balanced, again depending on the engine, however they do not absorb harmonics.

Next up is the crank and bearings, first of all you want this to be balanced. A good machine shop will be able to mount the crank onto a machine and spin it, they also tell the machine how much weight will be on each rod journal, and the computer tells the machinist how much weight needs to be added or subtracted. "ADDED!!!!" you say? Yes by drilling holes in the crank a metal known as mallory(sp?) can be added, it is actually heavier then the cast/forged metal the crank is made out of and thus allows "added" material. It does not really change the size of the item just the density, this should be the number one priority. Next up is bearings the vq dosnt have many options in this respect, unlike older engines, which is amazing due to bearings being one of the most important items. There are basically two different types of bearings oversized and undersized. Undersized bearings are simply that the inside diameter is smaller then stock. You will use these is with a custom smaller then stock bearing diameter crank, or if you have the crank machined down on the bearing surfaces. It could also be used to cause a tighter clearance, but i wouldn't recommend it. The other ones, well i take it back theres also stock size but you they don't really need explained do they? Anyway the other ones are oversized, these basically have a larger then stock inside diameter. This is where the real meat and potatoes lies. By running looser bearings, within reason, it allows for more expansion of the various parts they are attached too. The more power you make, the more heat it generates, and thus the more expansion there is. I don't think anyone will argue that metals expand when heated. So how do i figure clearance? Easy as per bearing manufacturers it should be .00075-.001 clearance per inch bearing surface diameter, in plain English? The bearings surface on a small block Chevy engine is 2.0, so it would be .00075x2 and .001x2 or .0015 to .002. On a vq with a diameter of 2.38 inches .001785 to .00238, the other thread i posted in i believe i said something like .0018 and .0025 because i did the calculations based on 2.4 inch crank, I personally like to run things a little bit loose. This is to account if something over heats, it may cause some odd noises until the engine is heated up, but it will be fine. Provided your not trying to gun the engine before the engine is operating temp. http://docs.google.com/viewer?a=v&q=...dJJltt4bxjiIaA For the quote from Clevite bearing manufacturer. Now this isn't without consequences, the tighter the clearance the thinner the oil you need. Why? The thicker stuff just cant squeeze into the smaller spaces, I guess the best way to describe it would be surface tension, I don't know if that's what exactly causes it, but it simply cannot squeeze into the smaller spaces. Like i said i don't know everything. =/ The advantages of thinner oil, is the engine runs smoother at start-up and colder weather, also it tends to be slicker so it allows everything to spin easier, and make more power. Since everything doesn't have to work as hard, emissions also tend to be less. The downside? Thin oil doesn't do well with higher power, and is easily "pushed" out of the way under extreme loads. The combination of this, and the removal of a large amount of zinc in oils in the 90's, caused countless flat tappet cam failures in aftermarket applications due to this type of cam receiving far more load then any cam in a modern engine, more on this later. Now with looser clearances, a thicker oil must be run, due to the thinner stuff "falling out" for a simple expression. Since the oil is thicker, it tends to stick to stuff better, it also causes more windage losses in the crankcase due to being heavier. The benefit to this however is thicker oil, due to a higher "surface tension" since i have no better way to explain it,and since its thicker has more resistance to the forces inside a high hp engine. There will also be a larger amount in between the bearings and your engine parts. A thinner oil would have trouble staying in place, and could cause problems. I wouldn't worry too much about windage in these applications since the vq comes stock with a windage tray/crank scraper. An easy comparison would be an engine to a rear end, you see what the clearances should be in a engine and the types of oil run. A rear end, if you every take the cover off and rock the pinion back and forth, you will see has large clearances. As such it must run a much much thicker oil. It also sees much higher forces then the engine due to the multiplicative effect the transmission has. A 500 ft lbs motor for example would be exerting 1000 ft lbs of force with a 2:1 gear ratio for exampleand we know what the oil change intervals on these parts are, with little failures. So what oil is best for you? Really it depends what you clearances are, if you build your own engine look at what other stock engines run in your power level/cylinder arrangement. (Since a v8 making 500 ft lbs of torque has less forces per cylinder and bearing then a v6 making 500 ft lbs torque at the same rpm.) If someone builds it for you consult them. Also multi-grade oils such as 20w-50, which means the oil will be no thinner then SAE20 at its coldest and will SAE50 at its operating temp, tend to hold up to sheering effects better then a straight grade like SAW30. However straight grade are said to be better for break in. I have no say one way or another as i haven't built enough engines to have an opinion, but it works so i wont argue it and ill always do it that way.

Edit: I almost forgot, torquing the main caps, it is very simple to over torque the mains and whatever is in the service manual should always be used!!!!!! No offense to any shop on here, however when i built my first engine I simply asked the machine shop and was told 75 ft lbs on the main caps. I did this and the crank wouldn't turn, i didn't check clearances, because frankly it was a stock rebuild why bother? I thought "wtf is going on here" so i took the crank out and re torqued without the crank to find clearance was at .0007!! After deciding the machine shop was crazy for a stock rebuild stock bearing build, I bought a service manual to find the correct torque was 65 ft lbs. Torquing the mains down to this amount, the bearing clearance was .0018 well within specs, bolted in the crank and retorqed to 65 ft lbs and she spun wonderfully with zero issues.

First of all the block itself, pretty simple stuff number of main bolts.

Early engines simply had two bolts per main like this.

This is perfectly acceptable, however not the greatest, not much uses this design anymore. Reasoning is that a four bolt main cap better distributes even load on the block to hold the crank in. It is not so that the crank be be torqued down tighter this is bad and more on it later on. Pic of a four bolt main in case no one has seen the vq. lol

Some engines such as General Motors ls/lq motors use 6 bolt mains, this does essentially the same thing as installing a girdle on a 2 or four bolt main engine with a girdle. (The thing that holds the crank in on the above picture although there are main caps under it.) It better distributes the load evenly across all the mains, this is an example of four bolt chevy engine without a girdle. As you can see nothing connects the main caps, the vq is the same way with the caps underneath the girdle.

This is a ls1 engine, as you can see there are holes on the side of the block where the main caps are, this causes the block to act as a girdle.

"So why is it important for everything to be even?" Great question, the answer is vibration and movement. If one cylinder produces 100 ft. lbs. of torque and another produces 80 ft. lbs. of torque then the force on the crank will be uneven. This can cause dangerous vibrations that can shatter engine parts, if its severe. Also the uneven pressure and vibrations can cause the crank to move forwards or back also known as "crank walk", ask the dsm guys about this one =P. As you can imagine something traveling at high rotational speeds and suddenly moving forwards and back can cause very sensational results, if your watching. If you own the car it will cause sensational tears. Harmonic balancer's are a part of this as well, some are weighted some are not, it varys by engine however they all have elastometers(sp?) or are liquid filled. This allows vibrations in the crank to travel into the balancer and be absorbed, instead of bouncing around inside the metal and causing bad things to happen. Flywheels are also sometimes balanced, again depending on the engine, however they do not absorb harmonics.

Next up is the crank and bearings, first of all you want this to be balanced. A good machine shop will be able to mount the crank onto a machine and spin it, they also tell the machine how much weight will be on each rod journal, and the computer tells the machinist how much weight needs to be added or subtracted. "ADDED!!!!" you say? Yes by drilling holes in the crank a metal known as mallory(sp?) can be added, it is actually heavier then the cast/forged metal the crank is made out of and thus allows "added" material. It does not really change the size of the item just the density, this should be the number one priority. Next up is bearings the vq dosnt have many options in this respect, unlike older engines, which is amazing due to bearings being one of the most important items. There are basically two different types of bearings oversized and undersized. Undersized bearings are simply that the inside diameter is smaller then stock. You will use these is with a custom smaller then stock bearing diameter crank, or if you have the crank machined down on the bearing surfaces. It could also be used to cause a tighter clearance, but i wouldn't recommend it. The other ones, well i take it back theres also stock size but you they don't really need explained do they? Anyway the other ones are oversized, these basically have a larger then stock inside diameter. This is where the real meat and potatoes lies. By running looser bearings, within reason, it allows for more expansion of the various parts they are attached too. The more power you make, the more heat it generates, and thus the more expansion there is. I don't think anyone will argue that metals expand when heated. So how do i figure clearance? Easy as per bearing manufacturers it should be .00075-.001 clearance per inch bearing surface diameter, in plain English? The bearings surface on a small block Chevy engine is 2.0, so it would be .00075x2 and .001x2 or .0015 to .002. On a vq with a diameter of 2.38 inches .001785 to .00238, the other thread i posted in i believe i said something like .0018 and .0025 because i did the calculations based on 2.4 inch crank, I personally like to run things a little bit loose. This is to account if something over heats, it may cause some odd noises until the engine is heated up, but it will be fine. Provided your not trying to gun the engine before the engine is operating temp. http://docs.google.com/viewer?a=v&q=...dJJltt4bxjiIaA For the quote from Clevite bearing manufacturer. Now this isn't without consequences, the tighter the clearance the thinner the oil you need. Why? The thicker stuff just cant squeeze into the smaller spaces, I guess the best way to describe it would be surface tension, I don't know if that's what exactly causes it, but it simply cannot squeeze into the smaller spaces. Like i said i don't know everything. =/ The advantages of thinner oil, is the engine runs smoother at start-up and colder weather, also it tends to be slicker so it allows everything to spin easier, and make more power. Since everything doesn't have to work as hard, emissions also tend to be less. The downside? Thin oil doesn't do well with higher power, and is easily "pushed" out of the way under extreme loads. The combination of this, and the removal of a large amount of zinc in oils in the 90's, caused countless flat tappet cam failures in aftermarket applications due to this type of cam receiving far more load then any cam in a modern engine, more on this later. Now with looser clearances, a thicker oil must be run, due to the thinner stuff "falling out" for a simple expression. Since the oil is thicker, it tends to stick to stuff better, it also causes more windage losses in the crankcase due to being heavier. The benefit to this however is thicker oil, due to a higher "surface tension" since i have no better way to explain it,and since its thicker has more resistance to the forces inside a high hp engine. There will also be a larger amount in between the bearings and your engine parts. A thinner oil would have trouble staying in place, and could cause problems. I wouldn't worry too much about windage in these applications since the vq comes stock with a windage tray/crank scraper. An easy comparison would be an engine to a rear end, you see what the clearances should be in a engine and the types of oil run. A rear end, if you every take the cover off and rock the pinion back and forth, you will see has large clearances. As such it must run a much much thicker oil. It also sees much higher forces then the engine due to the multiplicative effect the transmission has. A 500 ft lbs motor for example would be exerting 1000 ft lbs of force with a 2:1 gear ratio for exampleand we know what the oil change intervals on these parts are, with little failures. So what oil is best for you? Really it depends what you clearances are, if you build your own engine look at what other stock engines run in your power level/cylinder arrangement. (Since a v8 making 500 ft lbs of torque has less forces per cylinder and bearing then a v6 making 500 ft lbs torque at the same rpm.) If someone builds it for you consult them. Also multi-grade oils such as 20w-50, which means the oil will be no thinner then SAE20 at its coldest and will SAE50 at its operating temp, tend to hold up to sheering effects better then a straight grade like SAW30. However straight grade are said to be better for break in. I have no say one way or another as i haven't built enough engines to have an opinion, but it works so i wont argue it and ill always do it that way.

Edit: I almost forgot, torquing the main caps, it is very simple to over torque the mains and whatever is in the service manual should always be used!!!!!! No offense to any shop on here, however when i built my first engine I simply asked the machine shop and was told 75 ft lbs on the main caps. I did this and the crank wouldn't turn, i didn't check clearances, because frankly it was a stock rebuild why bother? I thought "wtf is going on here" so i took the crank out and re torqued without the crank to find clearance was at .0007!! After deciding the machine shop was crazy for a stock rebuild stock bearing build, I bought a service manual to find the correct torque was 65 ft lbs. Torquing the mains down to this amount, the bearing clearance was .0018 well within specs, bolted in the crank and retorqed to 65 ft lbs and she spun wonderfully with zero issues.

Last edited by jerryd87; 04-08-2011 at 10:04 AM. Reason: Better grammar hopefully

#2

As promised more stuff, here we go i left off on main bearings. A similar thing would be rod bearings, pretty much read what i typed on those and the same applys.

Above them are the rods, rods experience a massive amount of force. Why? Simple they change directions rapidly and move at extreme speeds with nothing to support them, unlike the pistons that have bores for support. There are a lot of types, most being H beam or I beam with a couple other variations, but 90% or more of the rods will be the above two. Pretty much any rod will come with top of the line ARP fasteners, some come with A1 H11 but most are ARP. Typically with domestics H beam are the way to go, however on imports such as the vq motor it seems that some of the I beams are just as strong. Why, I have no idea, it may be that the H beam structure is better designed to handle high torque and I beam better for high speeds. I honestly don't know and simply go with what is proven on a platform, as it is just speculation. In my previous engines it was GMPP "pink" rods because they where proven to handle over 600 hp and where cheap, think i paid 230 for them gm employee discount. That's my honest opinion, use w/e is proven because I honestly don't know why H beams are the way to go on some platforms and I beams on others. *shrug*

One thing to note however is the hp rating from manufacturers can be misleading. The reality is, hp is really just a fictional number based on a calculation, its torque vs rpms and gives a general idea of an engines ability. Torque is the actual power being made and is what actually breaks things. Hp is really just torque over time, that's the best way I've ever heard it explained. I can get into hp in another post but frankly that would require an entire different topic to fully explain. Again go with whats proven not what the manufacturer tells you. There are also two types of wrist pins, free floating and pressed in. Free floating float in the rod and piston and are held in by C clips, as far as i know all newer engines use these. Some older engines are free floating in the piston only, and a press has to be used to press them through the rod to the other side of the piston, they have no c clip. There is no real advantage to changing whats in the engine use, w/e it came with to be honest.

Oiling systems are another larger subject usually there are 4 types of pumps. Oem, with oem pressures and flow rates. High volume, which move a higher volume of oil however at a lower pressure then stock or the same pressure. High pressure, which have a much higher pressure then stock however flow the same or less then stock. Finally high flow high pressure pumps, the move a higher volume then stock at a higher pressure. I choose the last option if at all possible. Reasoning for this is higher pressure makes sure the pump is able to get oil to every part of the engine even under high forces from rotation and changing directing like the rotating assembly. High volume mixed with this ensures that the max amount of oil is at the bearings where needed at all times. Pretty simple and good reasoning. Some engines, such as solid lifter ohv engines, can cut off a portion of the flow to the heads since very little is needed for push rods, valves, and rocker arms. Every dohc engine is going to need as much oil as possible up there, to make sure the cams are lubed. Some engines also have oil squirters, *coughcoughvq35coughcough*, they are a little bit controversial. The benefit to them is plain and simple they cool the pistons, the potential downsides are they draw pressure from the oil system. Judging by pressures ive seen from vq35s, I don't think this is an issue like it may be on other systems. Just remember without them the only thing you have to cool the pistons is fuel, and the combustion chamber sees the highest temps in the engine. Pistons get too hot, and it will travel down the rod, if it continues it is going right to the bearings and causing increased expansion. I can imagine you know what i vote for. As far as i know the only difference between the standard pump and rev up pump is not pressure or volume but simple part strength, engine builders that know please comment. Nismo may be higher volume higher pressure but i would be pissed to pay that amount and it not be.

As far as i know the only difference between the standard pump and rev up pump is not pressure or volume but simple part strength, engine builders that know please comment. Nismo may be higher volume higher pressure but i would be pissed to pay that amount and it not be.

The final part on the shortblock, more or less, is the pistons. There are three major types and really it only matters on other platforms as all the aftermarket ones for the vq are forged. Cast are typically what come from the factory on most engine.(Not sure if the vq are forged or not?) They are weak, however are similar in ability to forged for handling knock/detonation as they flex a little but they are weaker. Hyper eutectic(sp?) are stronger then forged even, but it comes at a price as per a conversation with keith black some time ago.(A major piston manufacturer for domestics/custom engines.) Sorry i don't have the emails anymore from there tech, but you can call them to verify or email tech if you like to. The hyper's are very brittle vs forged or cast so while there tensile strength is much higher, and theoretically can handle more power good luck tuning on them. More then a couple knock/detonation events and your going to shatter them. Plus while they are stronger then forged its not by much. Finally forged its what everyone should go with hands down no matter the build. Some are stronger then others but its manufacturing process and design that provides most of this. There may be metallurgy differences but none of us will ever know unless we work for one of the company's that makes them. They are ALMOST as strong as hyper's, however they flex a lot more, allowing them to withstand more detonation/knock.

I forgot to have this in here yesterday so adding it now. Piston rings, the two major types are cast and moly coated. Most high performance engines use moly rings for there increased strength over standard ring. Cast rings are simply that cast iron(or is it cast steel?) rings. I'm not sure if moly are rings are cast in cast iron/steel then coated or are simply made out of chromoly(sp?) steel. Moly rings will take longer to break in but pretty much every engine will still break in within 1000 miles. the most important factor for rings is the gap. There is a simply chart for this which you multiply your bore size, IN INCHES, to whatever is on there.

http://www.wiseco.com/PDFs/Manuals/RingEndGap.pdf

So for a stock bore vq35de turbo it would be 3.76(95.5mm in inches) x .005 for the top ring and 3.76 x .0055 for the bottom. This would leave a ring gap of .0188 and .02068. Oil rings don't need adjusted they simply need to be at least .001 gap. For the higher hp motors they would probably want to go with the circle track/drag racing numbers. The rings also need to be staggered, the top ring should be at the 12 o'clock position, the second ring at the 4 o'clock and the oil rings at the 8 o'clock. This will help minimize blow by, and also minimize oil leaked into the combustion chamber off boost especially considering the larger end gaps.

Sbc standard pressure standard volume

Sbc melling high volume high pressure, not much can be seen the oil pickup hole is larger though.

Oem vs aftermarket rods

Overheated rod notice the discoloration rod every rod in the engine was over heated.

Cast vs forged piston

Cast piston(or appears to be)

hyper piston

Really hard to tell with pistons.

Ok now on to cooling systems, since it's a pretty easy one. There are two different kinds of coolant systems, each will require research for that particular engine. From what im reading it seems the vq is a standard cooling system, if thats wrong let me know. In this type of system the coolant enters the block first, it then cools the engine block, then moves up to the heads. Early small blocks are this type, gm lt/ls/lq engines are not. This cooling system is a poor setup for performance but is doable.

The second type of cooling system is known as a reverse flow. This type is available in pretty much every gm v8 now, and i believe the ecotec as well. Basically the coolant goes directly into the head into this system, OR it enters the block and immediately moves to the heads. This allows the heads, which are the hottest part of the engine due to being so close to the combustion event and also the exhaust going through them, to be cooled completely first. Then the coolant flows into the much cooler block and finally out to the radiator. Can't post much on this as a lot of the changes are in the block themselves.

Forward flow water pump

Reverse flow water pump

I have no idea if a reverse flow pump can be made, put on the vq, and work successfully. One easy way to cool an engine is removal of the thermostats. It appears that simply removing the two screws in the housing, will allow removal of the thermostat. This WILL cause the engine to take longer to get up to operating temp, the plus? Coolant temps will do down due to always flowing through the radiator, and also since there is nothing blocking the flow path, it should increase flow.

Above them are the rods, rods experience a massive amount of force. Why? Simple they change directions rapidly and move at extreme speeds with nothing to support them, unlike the pistons that have bores for support. There are a lot of types, most being H beam or I beam with a couple other variations, but 90% or more of the rods will be the above two. Pretty much any rod will come with top of the line ARP fasteners, some come with A1 H11 but most are ARP. Typically with domestics H beam are the way to go, however on imports such as the vq motor it seems that some of the I beams are just as strong. Why, I have no idea, it may be that the H beam structure is better designed to handle high torque and I beam better for high speeds. I honestly don't know and simply go with what is proven on a platform, as it is just speculation. In my previous engines it was GMPP "pink" rods because they where proven to handle over 600 hp and where cheap, think i paid 230 for them gm employee discount. That's my honest opinion, use w/e is proven because I honestly don't know why H beams are the way to go on some platforms and I beams on others. *shrug*

One thing to note however is the hp rating from manufacturers can be misleading. The reality is, hp is really just a fictional number based on a calculation, its torque vs rpms and gives a general idea of an engines ability. Torque is the actual power being made and is what actually breaks things. Hp is really just torque over time, that's the best way I've ever heard it explained. I can get into hp in another post but frankly that would require an entire different topic to fully explain. Again go with whats proven not what the manufacturer tells you. There are also two types of wrist pins, free floating and pressed in. Free floating float in the rod and piston and are held in by C clips, as far as i know all newer engines use these. Some older engines are free floating in the piston only, and a press has to be used to press them through the rod to the other side of the piston, they have no c clip. There is no real advantage to changing whats in the engine use, w/e it came with to be honest.

Oiling systems are another larger subject usually there are 4 types of pumps. Oem, with oem pressures and flow rates. High volume, which move a higher volume of oil however at a lower pressure then stock or the same pressure. High pressure, which have a much higher pressure then stock however flow the same or less then stock. Finally high flow high pressure pumps, the move a higher volume then stock at a higher pressure. I choose the last option if at all possible. Reasoning for this is higher pressure makes sure the pump is able to get oil to every part of the engine even under high forces from rotation and changing directing like the rotating assembly. High volume mixed with this ensures that the max amount of oil is at the bearings where needed at all times. Pretty simple and good reasoning. Some engines, such as solid lifter ohv engines, can cut off a portion of the flow to the heads since very little is needed for push rods, valves, and rocker arms. Every dohc engine is going to need as much oil as possible up there, to make sure the cams are lubed. Some engines also have oil squirters, *coughcoughvq35coughcough*, they are a little bit controversial. The benefit to them is plain and simple they cool the pistons, the potential downsides are they draw pressure from the oil system. Judging by pressures ive seen from vq35s, I don't think this is an issue like it may be on other systems. Just remember without them the only thing you have to cool the pistons is fuel, and the combustion chamber sees the highest temps in the engine. Pistons get too hot, and it will travel down the rod, if it continues it is going right to the bearings and causing increased expansion. I can imagine you know what i vote for.

As far as i know the only difference between the standard pump and rev up pump is not pressure or volume but simple part strength, engine builders that know please comment. Nismo may be higher volume higher pressure but i would be pissed to pay that amount and it not be.

As far as i know the only difference between the standard pump and rev up pump is not pressure or volume but simple part strength, engine builders that know please comment. Nismo may be higher volume higher pressure but i would be pissed to pay that amount and it not be.The final part on the shortblock, more or less, is the pistons. There are three major types and really it only matters on other platforms as all the aftermarket ones for the vq are forged. Cast are typically what come from the factory on most engine.(Not sure if the vq are forged or not?) They are weak, however are similar in ability to forged for handling knock/detonation as they flex a little but they are weaker. Hyper eutectic(sp?) are stronger then forged even, but it comes at a price as per a conversation with keith black some time ago.(A major piston manufacturer for domestics/custom engines.) Sorry i don't have the emails anymore from there tech, but you can call them to verify or email tech if you like to. The hyper's are very brittle vs forged or cast so while there tensile strength is much higher, and theoretically can handle more power good luck tuning on them. More then a couple knock/detonation events and your going to shatter them. Plus while they are stronger then forged its not by much. Finally forged its what everyone should go with hands down no matter the build. Some are stronger then others but its manufacturing process and design that provides most of this. There may be metallurgy differences but none of us will ever know unless we work for one of the company's that makes them. They are ALMOST as strong as hyper's, however they flex a lot more, allowing them to withstand more detonation/knock.

I forgot to have this in here yesterday so adding it now. Piston rings, the two major types are cast and moly coated. Most high performance engines use moly rings for there increased strength over standard ring. Cast rings are simply that cast iron(or is it cast steel?) rings. I'm not sure if moly are rings are cast in cast iron/steel then coated or are simply made out of chromoly(sp?) steel. Moly rings will take longer to break in but pretty much every engine will still break in within 1000 miles. the most important factor for rings is the gap. There is a simply chart for this which you multiply your bore size, IN INCHES, to whatever is on there.

http://www.wiseco.com/PDFs/Manuals/RingEndGap.pdf

So for a stock bore vq35de turbo it would be 3.76(95.5mm in inches) x .005 for the top ring and 3.76 x .0055 for the bottom. This would leave a ring gap of .0188 and .02068. Oil rings don't need adjusted they simply need to be at least .001 gap. For the higher hp motors they would probably want to go with the circle track/drag racing numbers. The rings also need to be staggered, the top ring should be at the 12 o'clock position, the second ring at the 4 o'clock and the oil rings at the 8 o'clock. This will help minimize blow by, and also minimize oil leaked into the combustion chamber off boost especially considering the larger end gaps.

Sbc standard pressure standard volume

Sbc melling high volume high pressure, not much can be seen the oil pickup hole is larger though.

Oem vs aftermarket rods

Overheated rod notice the discoloration rod every rod in the engine was over heated.

Cast vs forged piston

Cast piston(or appears to be)

hyper piston

Really hard to tell with pistons.

Ok now on to cooling systems, since it's a pretty easy one. There are two different kinds of coolant systems, each will require research for that particular engine. From what im reading it seems the vq is a standard cooling system, if thats wrong let me know. In this type of system the coolant enters the block first, it then cools the engine block, then moves up to the heads. Early small blocks are this type, gm lt/ls/lq engines are not. This cooling system is a poor setup for performance but is doable.

The second type of cooling system is known as a reverse flow. This type is available in pretty much every gm v8 now, and i believe the ecotec as well. Basically the coolant goes directly into the head into this system, OR it enters the block and immediately moves to the heads. This allows the heads, which are the hottest part of the engine due to being so close to the combustion event and also the exhaust going through them, to be cooled completely first. Then the coolant flows into the much cooler block and finally out to the radiator. Can't post much on this as a lot of the changes are in the block themselves.

Forward flow water pump

Reverse flow water pump

I have no idea if a reverse flow pump can be made, put on the vq, and work successfully. One easy way to cool an engine is removal of the thermostats. It appears that simply removing the two screws in the housing, will allow removal of the thermostat. This WILL cause the engine to take longer to get up to operating temp, the plus? Coolant temps will do down due to always flowing through the radiator, and also since there is nothing blocking the flow path, it should increase flow.

Last edited by jerryd87; 04-08-2011 at 10:40 AM. Reason: mo infos

#5

if anyone else has stuff to add feel free to pm me and i can add it to the first couple threads just makes my head hurt posting too much at once =P plus i start to forget stuff anyway gona update with a little more info other posts are getting too big so editing it into this one more to follow. gona try and get this done tonight

going to do cams and valvetrain next as heads are a huge subject and dosnt apply to most people on here.

valvetrain first major thing to consider here is valves springs and retainers. valves have a couple types i cant remember what type of steel most stock ones are made out of however pretty much every aftermarket intake valve is made of stainless. these are lighter weight then stock, they come in various sizes and can be flat bottomed or have a dish in them to slightly lower compression and also be slightly less weight. they are also available in full stem or cut stems. full stems will be heavier and stronger, cut stems will be lighter and flow better however ive seen a couple high rpm high power builds snap the heads off them im not sure if they where cut down more or what. i do know that some people run valves for other manufacturers to allow longer stems and more lift in ohv engines so it could just be mismatched valves my reservation is out i always used full body valves. oh yah forgot there are also hollow intake valves even lighter weight no downsides really as far as i know, dont think they make dished hollow valves though again i dont know everything and could be wrong. exhaust valves are alot more important then intake they take alot more abuse due to the high heat they are ALWAYS in contact with even as the gases are leaving the chamber, however intake valves are bigger and have small periods away from the hot exhuast gases and combustion events to help them cool down a little bit. exhaust valves are typically made of two things stainless steel and inconel(sp?) inconel as we all know is a stronger material in terms of resisting heat if your going high boost you want this, its the same thing turbine wheels are made out of for this reason with the exception of bw efr turbos new titanium aluminum ceramic omfgamazingness wheels. most inconel valves are going to be sodium filled as well im not sure why but it seems the sodium tends to keep the valves cooler, i dont know why or how but its been proven in many applications so im not going to argue. "you keep mentioning light weight, wouldnt you want heavy stuff to make sure it dosnt break?" no not in a valve train, the reason is that valvetrain springs arnt very strong and well there springs so they move alot. the heavier a valve is the harder it is for the spring to control it and get it closed in enough time at high rpms resulting in valve float or the valve staying partially open all the time at high rpms, this can cause bent valves and engine destruction. honestly i have no problem watching this happen as long as its not my engine and the owner says do it i shall watch with a grin, im a grenadier i like to watch **** go boom. if theres only one good set made for an engine like ours with the bc stuff use it. anything else with many options available contact the cam manufacturer and get there recommendation there is no exact science for the masses you have to trust the manufacturer if you have a problem and are using what they told you in the way they say they will more then likely help you out. titanium retainers plain and simple are lighter weight thus its easyer for the springs to control them. you want as little spring pressure as possible to control the valves, you do not i repeat DO NOT want to say "what do you recommend? ok whats the next size up?" shall we go look at the pics of hr cams with bc spring and retainers? bigger isnt always better especially if the cams dont make any more power by revving higher. really only wanna step up springs if you have valve float. springs are also available in many types. single spring, single spring with a help, dual spring, triple spring(i think i saw these once and only once pretty much super high revving super high displacement v8s) and beehive spring each one up just offers more pressure the exception is beehive springs. they look like a beehive and offer a progressive rate similar to the springs on your suspension, the best design EVER imho and many other peoples. can see pressures equal to dual spring setups with a single spring, less weight, and less cost. some pics for your viewing pressure then im gona go try and find some pictures to help explain cams as im going to need them.

also if anyone has questions and wants me to further explain something let me know and ill try or at least try and find someone who can and give them proper credit but keep it in these top two posts.

oem valves however also dished as you can see various forms of dishs are available.

stainless valves

inconel not sure if the inconel makes em blackish or if thats normal color i used stainless in my nitrous build oem for all others, the seats look new though so prob just since they are inconel =/

now to help find diagrams to help explain cams or make some if i cant, most of these pics are from google btw, ill post a couple pics of the last engine i built when im doing heads since you can see a little of my hand porting but it was a fs add so no major pics =/

single valve springs

beehive springs

dual valve spring with helper, you can see the big outer spring, the flat helper spring and a small secondary spring inside the helper, helper is more for stability then pressure

crazy *** triple valve spring, that thing gets into bind your f'ed

if someone wants me to get into coil bind, install height, open pressure, closed pressure let me know i will edit that in

going to do cams and valvetrain next as heads are a huge subject and dosnt apply to most people on here.

valvetrain first major thing to consider here is valves springs and retainers. valves have a couple types i cant remember what type of steel most stock ones are made out of however pretty much every aftermarket intake valve is made of stainless. these are lighter weight then stock, they come in various sizes and can be flat bottomed or have a dish in them to slightly lower compression and also be slightly less weight. they are also available in full stem or cut stems. full stems will be heavier and stronger, cut stems will be lighter and flow better however ive seen a couple high rpm high power builds snap the heads off them im not sure if they where cut down more or what. i do know that some people run valves for other manufacturers to allow longer stems and more lift in ohv engines so it could just be mismatched valves my reservation is out i always used full body valves. oh yah forgot there are also hollow intake valves even lighter weight no downsides really as far as i know, dont think they make dished hollow valves though again i dont know everything and could be wrong. exhaust valves are alot more important then intake they take alot more abuse due to the high heat they are ALWAYS in contact with even as the gases are leaving the chamber, however intake valves are bigger and have small periods away from the hot exhuast gases and combustion events to help them cool down a little bit. exhaust valves are typically made of two things stainless steel and inconel(sp?) inconel as we all know is a stronger material in terms of resisting heat if your going high boost you want this, its the same thing turbine wheels are made out of for this reason with the exception of bw efr turbos new titanium aluminum ceramic omfgamazingness wheels. most inconel valves are going to be sodium filled as well im not sure why but it seems the sodium tends to keep the valves cooler, i dont know why or how but its been proven in many applications so im not going to argue. "you keep mentioning light weight, wouldnt you want heavy stuff to make sure it dosnt break?" no not in a valve train, the reason is that valvetrain springs arnt very strong and well there springs so they move alot. the heavier a valve is the harder it is for the spring to control it and get it closed in enough time at high rpms resulting in valve float or the valve staying partially open all the time at high rpms, this can cause bent valves and engine destruction. honestly i have no problem watching this happen as long as its not my engine and the owner says do it i shall watch with a grin, im a grenadier i like to watch **** go boom. if theres only one good set made for an engine like ours with the bc stuff use it. anything else with many options available contact the cam manufacturer and get there recommendation there is no exact science for the masses you have to trust the manufacturer if you have a problem and are using what they told you in the way they say they will more then likely help you out. titanium retainers plain and simple are lighter weight thus its easyer for the springs to control them. you want as little spring pressure as possible to control the valves, you do not i repeat DO NOT want to say "what do you recommend? ok whats the next size up?" shall we go look at the pics of hr cams with bc spring and retainers? bigger isnt always better especially if the cams dont make any more power by revving higher. really only wanna step up springs if you have valve float. springs are also available in many types. single spring, single spring with a help, dual spring, triple spring(i think i saw these once and only once pretty much super high revving super high displacement v8s) and beehive spring each one up just offers more pressure the exception is beehive springs. they look like a beehive and offer a progressive rate similar to the springs on your suspension, the best design EVER imho and many other peoples. can see pressures equal to dual spring setups with a single spring, less weight, and less cost. some pics for your viewing pressure then im gona go try and find some pictures to help explain cams as im going to need them.

also if anyone has questions and wants me to further explain something let me know and ill try or at least try and find someone who can and give them proper credit but keep it in these top two posts.

oem valves however also dished as you can see various forms of dishs are available.

stainless valves

inconel not sure if the inconel makes em blackish or if thats normal color i used stainless in my nitrous build oem for all others, the seats look new though so prob just since they are inconel =/

now to help find diagrams to help explain cams or make some if i cant, most of these pics are from google btw, ill post a couple pics of the last engine i built when im doing heads since you can see a little of my hand porting but it was a fs add so no major pics =/

single valve springs

beehive springs

dual valve spring with helper, you can see the big outer spring, the flat helper spring and a small secondary spring inside the helper, helper is more for stability then pressure

crazy *** triple valve spring, that thing gets into bind your f'ed

if someone wants me to get into coil bind, install height, open pressure, closed pressure let me know i will edit that in

Last edited by jerryd87; 04-07-2011 at 08:08 PM.

#8

Living in 350Z

iTrader: (30)

Join Date: May 2009

Location: Spartanburg(SparkleCity), SC

Posts: 4,293

Likes: 0

Received 2 Likes

on

2 Posts

Good job...

I have something to add... punctuation.

But seriously, I think that it's probably good information, but I couldn't make it through reading the first post.

That having been said, thanks for sharing. I love seeing information/knowledge being shared on the forums, it's the main reason we're all here, to learn & share.

I have something to add... punctuation.

But seriously, I think that it's probably good information, but I couldn't make it through reading the first post.

That having been said, thanks for sharing. I love seeing information/knowledge being shared on the forums, it's the main reason we're all here, to learn & share.

#9

I'll go through and edit the posts, im horrid at grammar and spelling and when i get on a roll it just gets worse. I could be wrong however filling 10w30 in the cold always made it poor a lot slower. 75w140 mobile one synthetic that i had in my Camaro rear end when i rebuilt it was so thick i couldn't get it all out on a 20 degree day, had to take it inside to warm it up and it thinned out. Mayby some oils and greases are different, but anything i have ever encountered has been thicker in the cold thinner in the warmth. Some things i posted are things i have learned and been told and i try to mention that and others i have learned from experience, oils where one of the experience things. Ohio hits up to -30 with wind chill and **** always seems to break in the winter, rear end oil is the easiest to see the difference because it usually has such a wide range.

Again ill edit the previous posts before continuing i need to edit the piston section anyway due to forgetting to add in piston rings =/

Putting this here to try and keep information close to the top of the thread.

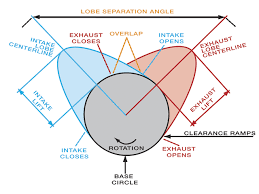

Holy **** what is that!?!?! That is the chart/picture i was trying to find last night to help explain cams. Alot of people may argue cams do not make power they only shape it, im not going to get into that but just be aware of it.

Ok so a basic bit of info for cams, in case you dint know they spin at have the speed of the crankshaft. Why? Its because we all have 4 stroke engines. Intake stroke to draw air/fuel in, compression to compress it and prepare for the power stroke, power stroke coming down to make the power, and exhaust to vent it all out. If they where rotating at the same speed then the intake cam would be open every time the piston goes down and we would loose all our power out the intake valve during combustion.

So onto the picture, as you can see there is a intake and exhaust lift, pretty simple the larger the lift the more space air has to enter and exit the engine. More lift means the engine will have an easier time getting air into the engine, less lift means less air will come in but it will have a higher velocity. When the air enters the combustion chamber it actually swirls and keeps the fuel suspended. The higher the velocity the more the swirl and the more efficient the combustion event. How much lift you want will depend on the size of the engine and your power goals. You have to be careful however too much lift and there is a risk of hitting the valves on the piston, then your ****ed. =/ Another important factor with lift is "ramp up" this is basically how fast the cam gets to its max lift, ramp up on our cams isn't too severe and it has a much more impact on larger engine that need as much airflow as soon as possible. There isn't really a way to measure ramp up unfortunately other then looking at the cam.

Vq35de cams with a gradual ramp up.

Ls1 cams, as you can see the cam moves to its max lift at a much more aggressive rate and stays there longer then our cams.

After that we have duration, which is just how long the cams hold the valves open in CRANKSHAFT degrees. Remember the cams rotate at half the speed of the crank, so 2 crankshaft degrees is 1 cam degree, 272 cam degrees would have the valves open during two different strokes. Be kind of a waste to have the intake cam open during the the compression stroke or the exhaust open on the power stroke. Most of our cams are rated in straight duration, most domestics are rated at .050 lift as this is a more important number. A person will get no reasonable flow from the cam before .050 lift so if duration is 272, but only 220 at .050 lift you don't have a very large cam for meaningful flow. Duration has a major impact on ramp up for a cam, the higher your rpm the more duration you want. This allows the heads more time to flow gases in and out of the combustion chamber at high speeds where there is more gases being produced.

Number three on a cam is the lobe center line. This is how many degrees, again crankshaft degrees, the crank must rotate from top dead center until the cam reaches its peak, or center line. Consult the first picture if you are having trouble understanding this. really all other readings on the cam tie into this and are based off this. On our engines and other variable valve timing engines its important to know the center line. By advancing cam timing, or moving the cam center line so events happen sooner this will help low end power as your starting everything sooner similar to how advancing timing works. Retarding the cam timing starts everything later and will sacrifice low end and mid range power to make a little more up top. It has a more pronounced effect on n/a engines with variable valve timing as exhaust scavenging can help pull air into the combustion chamber by having the intake and exhaust valve open longer together.

The final portion of important cam tech is overlap. If you have every heard a all out drag car idle you know what overlap is. That crazy idle they have is caused by over lap. Put simply the greater overlap there is in a cam the greater the exhaust scavenging, allowing more air to fill the combustion chamber at high rpms. The downside is this limits the power band of the engine. The less overlap, the less the exhaust is able to help scavenge air into the combustion chamber however since less air escapes out the exhaust at low rpms the larger the power band is, at the cost of peak power. With turbocharged applications exhaust scavenging isn't as important as we are forcing air into the combustion chamber already. However since the air is going into the engine compressed and out of the engine uncompressed, it is advantageous to have a larger duration and lift on the exhaust then the intake. Call any domestic cam manufacturer that doesn't have variable cam timing and they will all recommend a reverse lobe cam for turbo applications. That is a cam with larger lift and duration on the exhaust then the intake and a wide lobe separation angle. If you would like to get more in depth with cams car craft has an amazing article that helped me choose the cam in my nitrous motor a couple years ago. http://www.carcraft.com/techarticles...sic/index.html

Again ill edit the previous posts before continuing i need to edit the piston section anyway due to forgetting to add in piston rings =/

Putting this here to try and keep information close to the top of the thread.

Holy **** what is that!?!?! That is the chart/picture i was trying to find last night to help explain cams. Alot of people may argue cams do not make power they only shape it, im not going to get into that but just be aware of it.

Ok so a basic bit of info for cams, in case you dint know they spin at have the speed of the crankshaft. Why? Its because we all have 4 stroke engines. Intake stroke to draw air/fuel in, compression to compress it and prepare for the power stroke, power stroke coming down to make the power, and exhaust to vent it all out. If they where rotating at the same speed then the intake cam would be open every time the piston goes down and we would loose all our power out the intake valve during combustion.

So onto the picture, as you can see there is a intake and exhaust lift, pretty simple the larger the lift the more space air has to enter and exit the engine. More lift means the engine will have an easier time getting air into the engine, less lift means less air will come in but it will have a higher velocity. When the air enters the combustion chamber it actually swirls and keeps the fuel suspended. The higher the velocity the more the swirl and the more efficient the combustion event. How much lift you want will depend on the size of the engine and your power goals. You have to be careful however too much lift and there is a risk of hitting the valves on the piston, then your ****ed. =/ Another important factor with lift is "ramp up" this is basically how fast the cam gets to its max lift, ramp up on our cams isn't too severe and it has a much more impact on larger engine that need as much airflow as soon as possible. There isn't really a way to measure ramp up unfortunately other then looking at the cam.

Vq35de cams with a gradual ramp up.

Ls1 cams, as you can see the cam moves to its max lift at a much more aggressive rate and stays there longer then our cams.

After that we have duration, which is just how long the cams hold the valves open in CRANKSHAFT degrees. Remember the cams rotate at half the speed of the crank, so 2 crankshaft degrees is 1 cam degree, 272 cam degrees would have the valves open during two different strokes. Be kind of a waste to have the intake cam open during the the compression stroke or the exhaust open on the power stroke. Most of our cams are rated in straight duration, most domestics are rated at .050 lift as this is a more important number. A person will get no reasonable flow from the cam before .050 lift so if duration is 272, but only 220 at .050 lift you don't have a very large cam for meaningful flow. Duration has a major impact on ramp up for a cam, the higher your rpm the more duration you want. This allows the heads more time to flow gases in and out of the combustion chamber at high speeds where there is more gases being produced.

Number three on a cam is the lobe center line. This is how many degrees, again crankshaft degrees, the crank must rotate from top dead center until the cam reaches its peak, or center line. Consult the first picture if you are having trouble understanding this. really all other readings on the cam tie into this and are based off this. On our engines and other variable valve timing engines its important to know the center line. By advancing cam timing, or moving the cam center line so events happen sooner this will help low end power as your starting everything sooner similar to how advancing timing works. Retarding the cam timing starts everything later and will sacrifice low end and mid range power to make a little more up top. It has a more pronounced effect on n/a engines with variable valve timing as exhaust scavenging can help pull air into the combustion chamber by having the intake and exhaust valve open longer together.

The final portion of important cam tech is overlap. If you have every heard a all out drag car idle you know what overlap is. That crazy idle they have is caused by over lap. Put simply the greater overlap there is in a cam the greater the exhaust scavenging, allowing more air to fill the combustion chamber at high rpms. The downside is this limits the power band of the engine. The less overlap, the less the exhaust is able to help scavenge air into the combustion chamber however since less air escapes out the exhaust at low rpms the larger the power band is, at the cost of peak power. With turbocharged applications exhaust scavenging isn't as important as we are forcing air into the combustion chamber already. However since the air is going into the engine compressed and out of the engine uncompressed, it is advantageous to have a larger duration and lift on the exhaust then the intake. Call any domestic cam manufacturer that doesn't have variable cam timing and they will all recommend a reverse lobe cam for turbo applications. That is a cam with larger lift and duration on the exhaust then the intake and a wide lobe separation angle. If you would like to get more in depth with cams car craft has an amazing article that helped me choose the cam in my nitrous motor a couple years ago. http://www.carcraft.com/techarticles...sic/index.html

Last edited by jerryd87; 04-08-2011 at 11:40 AM.

#12

New Member

iTrader: (10)

Join Date: May 2005

Location: Jersey, New

Posts: 7,146

Likes: 0

Received 0 Likes

on

0 Posts

I'll go through and edit the posts, im horrid at grammar and spelling and when i get on a roll it just gets worse. I could be wrong however filling 10w30 in the cold always made it poor a lot slower. 75w140 mobile one synthetic that i had in my Camaro rear end when i rebuilt it was so thick i couldn't get it all out on a 20 degree day, had to take it inside to warm it up and it thinned out. Mayby some oils and greases are different, but anything i have ever encountered has been thicker in the cold thinner in the warmth. Some things i posted are things i have learned and been told and i try to mention that and others i have learned from experience, oils where one of the experience things. Ohio hits up to -30 with wind chill and **** always seems to break in the winter, rear end oil is the easiest to see the difference because it usually has such a wide range.

Again ill edit the previous posts before continuing i need to edit the piston section anyway due to forgetting to add in piston rings =/

Again ill edit the previous posts before continuing i need to edit the piston section anyway due to forgetting to add in piston rings =/

#13

Mid350Z is correct, the first number is cold viscosity and the second is hot viscosity. I read in modified mag sometime back that for F/I applications you want the two numbers as close together as possible while using 30 as the hot number minimum.

OP, there seems like some good info in here, but you have to break it into some paragraphs please. Otherwise its very difficult to read

OP, there seems like some good info in here, but you have to break it into some paragraphs please. Otherwise its very difficult to read

#15

Registered User

iTrader: (1)

another easy way to help cool an engine is removal of the thermostats. it appears that simply removing the two screws in the housing will allow removal of the thermostat. this WILL cause the engine to take longer to get up to operating temp, the plus? coolant temps will do down due to always flowing through the radiator and also since there is nothing blocking the flow path it should increase flow, im going to have hal do this when i take my car down to him.(sorry shariff if your reading this i can get my mom to drive 6 hours each way to pick it up from hal but she said no way to 12 hours each way even then i had to knock 600 bucks off what she owes me)

#16

New Member

iTrader: (44)

Mid350Z is correct, the first number is cold viscosity and the second is hot viscosity. I read in modified mag sometime back that for F/I applications you want the two numbers as close together as possible while using 30 as the hot number minimum.

OP, there seems like some good info in here, but you have to break it into some paragraphs please. Otherwise its very difficult to read

OP, there seems like some good info in here, but you have to break it into some paragraphs please. Otherwise its very difficult to read

#17

In the past I have run everything from 0W40 to 15W50 and have blown motors on all of them. I am now running Brad Penn 10W30 and will be logging temps and pressures over a variety of ambient temps to see what the results show.

The research I have done also points me toward using oils that have higher levels of Zinc and Phosphorus can help reduce friction at high temps. These oils should only be used if you have deleted your CATS though, or you will most likely foul them.

#18

I know some petroleum engineers who can't give me consistent answers on lubrication technology or selection, yet, each one has a firm opinion on the subject.

There are so many other proven engine related facts that this thread could shed light on without ever mentioning lube and I think that's the way it should go.

To play devil's advocate, I've been told multiple times that the bigger the range the better, (but with no mention of FI.) The theory being that only synthetics can offer such a broad range and give you "the best of all worlds." So if I use 0w40, I can start the car on Jan 15 @ -30°C and the oil will rush to the parts with the viscosity of water and if I beat the p!ss out of it in July at +30°C the thick oil will... Be "better" however it is that the world came to accept that hot, thick oil is better...

Just another opinion, though, and I have never found enough convincing and CONSISTENT info to fully buy into one theory.

Anyway, I feel like I/we are thread jacking, so, sorry about that. But I doubt this thread is structured enough to stop this from happening.

#20

The 10W30 rating means there exists and SAE flow experiment which has flow standards at a low temperature (Winter standard) and at a high temperature (operating temperature). The flowrate is corrected for temperature and hence you have a lower number for a winter value, and ah igher number for the operating temperature value. This does not mean it flows better cold than hot, but it does mean that it maintains viscosity at a higher temperature. a straight SAE 20 oil for example, will be too thin to effectively lubricate at high temperature, but work great at low temperature. An SAE50 oil will lubricate well at operating temperature, but suffer from poor flow properties, high viscosity, low oil pump efficiency during start-up and warm up.

Im having trouble finding the pic of a top fuel dragster bearing after a race as it was in an old issue of hot rod magazine that i threw out. However here is a 900 hp Nascar bearing after a race http://www.aera.org/ep/downloads/ep8/EPQ409_26-27.pdf its page two top left picture. You can see what just 500 miles at high power does and explains the need for thicker oil to resist extra forces.

As a side note more zinc is MUCH better then low zinc oils. Until the 90's it was a primary lubricant in all oils, however with the switch to ohc engines and roller cams less lubricant was needed when compared to a flat tappet cam.

As such zinc was removed to cater to the oem's, this combined with weaker metals from china caused numerous failures in cams. The solution was to move to diesel oils like Rotella T which still contained high zinc content. With current emissions standards however shell is removing zinc from this oil as well. The option is racing oils which are made specifically for high output engines and contain more zinc or to purchase gm break in addative.

The part number on this keeps changing so you will have to see a gm dealer for the current one, added to 5 quarts of oil it adds 700ppm of zinc.(I'm not even going to try and spell the proper name for it.) Personally i am going to go for Pennzoil's 202-50 racing oil as it is thicker and has zinc already in it.

Perfect showing of the resistance to loads, the top one is a low viscosity liquid and the bottom is a high viscosity liquid i know its from Wikipedia but its the best image I've ever seen to explain this. If anyone wants to reformat my posts to help out feel free and pm me so i can update them and try and keep the important stuff close to the top. Numbers and science are my strong suit, im horrible with language and grammar. =/

Last edited by jerryd87; 04-08-2011 at 10:02 AM.