How to separate front upper control arm?

#3

Registered User

You'll need a ball joint removal tool. The lower end of the ball joint it tapered where it fits into the upper end of the axle assembly. You can't break it loose without the proper tool to put lots of pressure on the end of the stud. Leave the nut loose on the threads after removing the cotter pin to keep from damaging the threads.

Last edited by winchman; 04-11-2010 at 11:09 AM.

#5

New Member

iTrader: (15)

You'll need a ball joint removal tool. The lower end of the ball joint it tapered where it fits into the upper end of the axle assembly. You can't break it loose without the proper tool to put lots of pressure on the end of the stud. Leave the nut loose on the threads after removing the cotter pin to keep from damaging the threads.

However, I think he is just trying to remove the upper A-arm so he will not need a ball joint remover since the ball joint is not pressed into the spindle/knuckle. It is pressed into the upper A-arm itself. A hearty whack with a 16oz hammer was all I needed once the pin and nut were removed. My SPL arms came with their own new ball joints so there was no need to remove the stock ones from the stock arms.

#7

In general this is absolutely correct.

However, I think he is just trying to remove the upper A-arm so he will not need a ball joint remover since the ball joint is not pressed into the spindle/knuckle. It is pressed into the upper A-arm itself. A hearty whack with a 16oz hammer was all I needed once the pin and nut were removed. My SPL arms came with their own new ball joints so there was no need to remove the stock ones from the stock arms.

However, I think he is just trying to remove the upper A-arm so he will not need a ball joint remover since the ball joint is not pressed into the spindle/knuckle. It is pressed into the upper A-arm itself. A hearty whack with a 16oz hammer was all I needed once the pin and nut were removed. My SPL arms came with their own new ball joints so there was no need to remove the stock ones from the stock arms.

Trending Topics

#8

New Member

iTrader: (13)

I took mine off last week. If that nut is spinning all the internals of the arm are spinning too which = broken arm (I'm assuming). The big nut underneath just came right off for me. I would get the grinder out and have some fun since I believe the OEM arm is useless anyway

#10

Registered User

iTrader: (10)

Join Date: Aug 2007

Location: kansas city

Posts: 607

Likes: 0

Received 0 Likes

on

0 Posts

you simply need to apply pressure to the upper part of the balljoint to reapply that pressure with the spindle. this will keep the balljoint from spinning and allow the nut to loosen. i would recommend placing a pry bar on the top of the balljoint and leverage it against the inner strut well, all while loosening the nut. or the use of an impact may be sufficient as the nut is not a lockint nut and once freed will come off easily.

since this is the case, after the nut comes off the balljoint should easily come out of the spindle--most likely pop out on its own as the force from the bushings will pull it up on its own.

Last edited by bimmertech; 04-11-2010 at 03:58 PM.

#11

Registered User

Join Date: Apr 2010

Location: New York

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

I signed up to tell you this:

I did the same job on my G35.

The tool you will need is a Picklefork.

Purchase or Rent it at an autozone or something similar in the area.

Put the picklefork in the join, take a mallet and bang bang bang the fork as hard as you can around the bolt. You will put pressure on the ball joint so the nut will come loose.

Took me about 3 days on my G to figure this out.

I did the same job on my G35.

The tool you will need is a Picklefork.

Purchase or Rent it at an autozone or something similar in the area.

Put the picklefork in the join, take a mallet and bang bang bang the fork as hard as you can around the bolt. You will put pressure on the ball joint so the nut will come loose.

Took me about 3 days on my G to figure this out.

#13

Registered User

iTrader: (9)

Join Date: Aug 2008

Location: Dallas, TX

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

If he's not planning on re-selling his stock a-arms he could just use a pair of pliers or a robo-grip or something similar to grip the rubber covering where the arrow is point in the picture. If you squeeze hard enough you'll grip the metal rod underneath and that will allow you to unscrew the bolt without the whole thing spinning around.

#14

If he's not planning on re-selling his stock a-arms he could just use a pair of pliers or a robo-grip or something similar to grip the rubber covering where the arrow is point in the picture. If you squeeze hard enough you'll grip the metal rod underneath and that will allow you to unscrew the bolt without the whole thing spinning around.

#15

Registered User

iTrader: (23)

Join Date: Apr 2008

Location: Georgia

Posts: 694

Likes: 0

Received 0 Likes

on

0 Posts

^ That or the pickle fork (which is a rental tool, so you don't have to buy one)

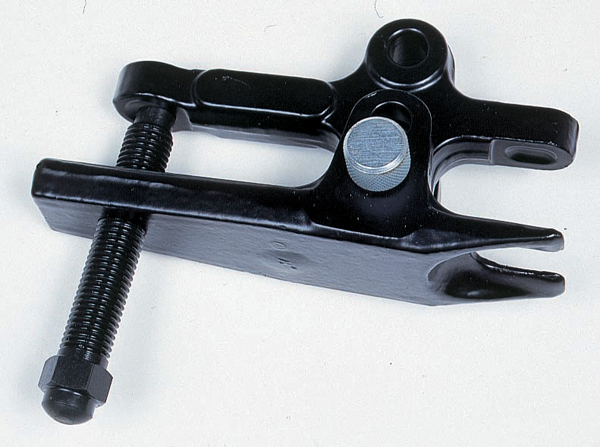

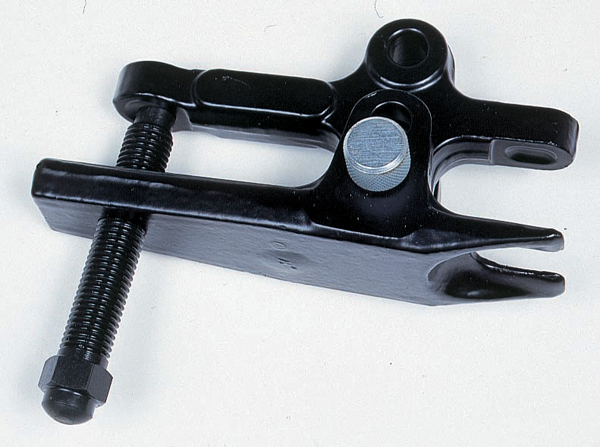

This won't help you get the nut off, but I have one of these:

Useful for separating balljoints, less chance of damaging the boot compared to the pickle fork.

This won't help you get the nut off, but I have one of these:

Useful for separating balljoints, less chance of damaging the boot compared to the pickle fork.

#16

finally got these b!tches out!!!!

All those tools that were recommended were failed at the job, I had to figured out my own way to do it.

All you need is to remove the you inner bolts near the struts, then flip it outward, tilt it upward or downward to put pressure on the balljoint, then remove the nuts.

These pics will explain everything!

This is will be a great guide for anyone that is lowered on coilover and want to switch out the front cambers.

All those tools that were recommended were failed at the job, I had to figured out my own way to do it.

All you need is to remove the you inner bolts near the struts, then flip it outward, tilt it upward or downward to put pressure on the balljoint, then remove the nuts.

These pics will explain everything!

This is will be a great guide for anyone that is lowered on coilover and want to switch out the front cambers.

#17

Registered User

iTrader: (2)

Join Date: Apr 2008

Location: Alberta

Posts: 139

Likes: 0

Received 0 Likes

on

0 Posts

Wow man that looks like one hell of a process. I just installed my Ichiba A arms with my KW's and when I undid that bolt the A arm popped right off. Hopefully you have better luck puttin it all together

#19

Registered User

iTrader: (8)

Join Date: Sep 2002

Location: Charlottesville, Virginia

Posts: 5,753

Likes: 0

Received 4 Likes

on

4 Posts

#20

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

ICE, please carefully inspect your brake lines for any cracks and your abs lines..........from that pic, you didnt remove the brake or abs line from the strut mounts and you are pulling on them quite badly!

you may not have a leak in brake fluid now?? but if you did give it a tear, then a tear can turn to a failure down the road......

-J

you may not have a leak in brake fluid now?? but if you did give it a tear, then a tear can turn to a failure down the road......

-J