cast vs tubular manifolds

#2

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

CAST:

Well, ive seen some shotty cast ones before, where we took the time to have them sand blasted and went for a smooth inside....there was too much chunk of cast to our liking...we were worried pieces would piece off and enter the system/turbo.

but they held up strong, never cracked, etc......heavy and solid.

TUBE:

Ive seen some purdy looking tube ones, light weight and all, but holding up the weight of a turbo and many heat cycles later, ive seen them crack....

ALL:

Not to say thats how they all are, but just what ive seen.........I would hopefully see if this thread yeilds some feedback from those that have them and you can get some solid answers to your research and make a good decision on whats good for you. I wouldn't care which one i bought, so long as it was deemed reliable and i only had to install it once!!

-j

Well, ive seen some shotty cast ones before, where we took the time to have them sand blasted and went for a smooth inside....there was too much chunk of cast to our liking...we were worried pieces would piece off and enter the system/turbo.

but they held up strong, never cracked, etc......heavy and solid.

TUBE:

Ive seen some purdy looking tube ones, light weight and all, but holding up the weight of a turbo and many heat cycles later, ive seen them crack....

ALL:

Not to say thats how they all are, but just what ive seen.........I would hopefully see if this thread yeilds some feedback from those that have them and you can get some solid answers to your research and make a good decision on whats good for you. I wouldn't care which one i bought, so long as it was deemed reliable and i only had to install it once!!

-j

#4

Vendor - Former Vendor

iTrader: (11)

Join Date: Oct 2003

Location: San Diego

Posts: 1,353

Likes: 0

Received 0 Likes

on

0 Posts

Here are some of the high-end tubular manifolds we build for our 350Z/G35 twin turbo kit.These manifolds are made out of 321 SS(can operate continously above 2000F), have 1 3/4" OD (1 5/8" ID) primaries and use Burns stainless merge collectors.Manifolds as extravagant as this is designed for high horsepower applications that require a tremendous amount of exhaust-flow without creating too much back pressure.Alot of the cast manifolds create tons of back pressure and we have seen back pressure as high as 4 to 1. So this means 4 psi of back pressure for every 1 psi of boost pressure! With a tubular header like this,we typically see a 1 to 1 ratio. Less back pressure means less exhaust gas temp.With less back pressure you can run more ignition advance and make more power.There is more to it then that but for the most part,this is a pretty accurate statement.Also if tubular headers are made right,you can get many,many trouble free miles out of them.I have over 40K daily driven,dynoed,raced miles on mine so far and no cracks.

Last edited by TurboTim; 02-04-2009 at 01:43 PM.

#5

Vendor - Former Vendor

iTrader: (12)

Cast manifolds usually last longer, are stronger, and are much less likely to crack. This is why we use cast manifolds on our turbo kits (/shamless plug  )

)

That is not to say some manifolds like the one Tim posted above won't be able to do the job properly. Unfortunately most of these tubular manifolds are not as high quality as Tim's - I am sure he can attest to that.

-George

GT Motorsports

)

)That is not to say some manifolds like the one Tim posted above won't be able to do the job properly. Unfortunately most of these tubular manifolds are not as high quality as Tim's - I am sure he can attest to that.

-George

GT Motorsports

#6

Registered User

*cough* *cough* EBAY KITS *cough* *cough*

#8

Vendor - Former Vendor

iTrader: (11)

Join Date: Oct 2003

Location: San Diego

Posts: 1,353

Likes: 0

Received 0 Likes

on

0 Posts

Cast manifolds usually last longer, are stronger, and are much less likely to crack. This is why we use cast manifolds on our turbo kits (/shamless plug  )

)

That is not to say some manifolds like the one Tim posted above won't be able to do the job properly. Unfortunately most of these tubular manifolds are not as high quality as Tim's - I am sure he can attest to that.

-George

GT Motorsports

)

)That is not to say some manifolds like the one Tim posted above won't be able to do the job properly. Unfortunately most of these tubular manifolds are not as high quality as Tim's - I am sure he can attest to that.

-George

GT Motorsports

This is true George.Alot of the tubular manifolds are just slapped together.We have even seen them Mig welded,ground down and then Tigged over to make them look pretty.LOL.We get pretty serious about building our manifolds since we started off building headers for alot of road race cars and that sort of thing which need headers to be light,strong and not crack

Last edited by TurboTim; 02-04-2009 at 09:59 PM.

#10

Registered User

iTrader: (16)

Join Date: Mar 2004

Location: Nashville, TN

Posts: 2,939

Likes: 0

Received 0 Likes

on

0 Posts

I can see the benefits of either and I personally feel each has its own place. Cast for space, relability, ease. But, there is a reason why almost ALL turbo cars use tubular for high HP. When was the last time you saw someone trying to push serious power on a supra with a cast mani?

If the tubular manifold is done correctly, you really should never have a problem with cracking. Yes, it can happen, but the possibility is very slim.

If the tubular manifold is done correctly, you really should never have a problem with cracking. Yes, it can happen, but the possibility is very slim.

#11

Vendor - Former Vendor

iTrader: (12)

I can see the benefits of either and I personally feel each has its own place. Cast for space, relability, ease. But, there is a reason why almost ALL turbo cars use tubular for high HP. When was the last time you saw someone trying to push serious power on a supra with a cast mani?

If the tubular manifold is done correctly, you really should never have a problem with cracking. Yes, it can happen, but the possibility is very slim.

If the tubular manifold is done correctly, you really should never have a problem with cracking. Yes, it can happen, but the possibility is very slim.

I do agree with you that for a one off high horsepower car, tubular manifold would be the way to go, you can't really do a one off cast manifold, it would be too expensive and the flexibility isn't their.

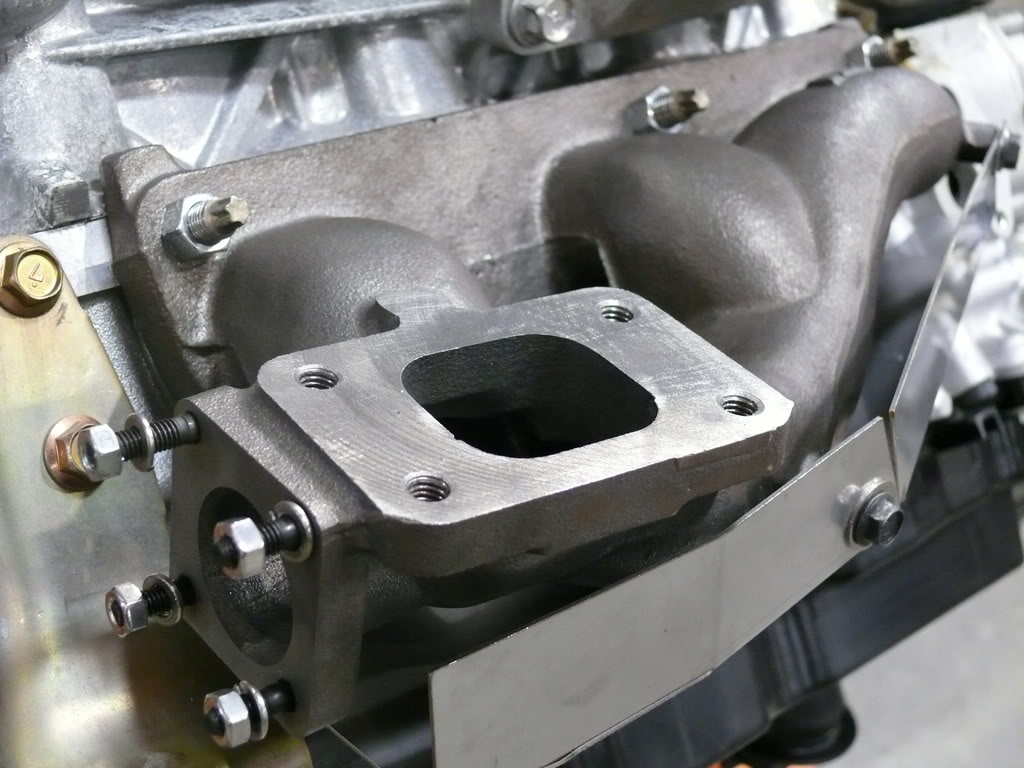

Here are some pics of our manifolds:

#12

Registered User

iTrader: (16)

Join Date: Mar 2004

Location: Nashville, TN

Posts: 2,939

Likes: 0

Received 0 Likes

on

0 Posts

OEM doesnt do it for the sole reason of reliablity. It is alot easier, and cost effective for a manufacturer to design a cast then to design a tubular manifold.

Cast can crack just as easy as tubular. Iv seen many cast manifolds crack on completely stock nonturbo cars/trucks. Even my greddy manifolds cracked. Proper design still plays a big role in reliability.

With that said I think both can be a very viable option, but would rather have a properly designed tubular manifold (personal choice).

Cast can crack just as easy as tubular. Iv seen many cast manifolds crack on completely stock nonturbo cars/trucks. Even my greddy manifolds cracked. Proper design still plays a big role in reliability.

With that said I think both can be a very viable option, but would rather have a properly designed tubular manifold (personal choice).

Last edited by thawk408; 02-04-2009 at 03:42 PM.

#13

Vendor - Former Vendor

iTrader: (12)

OEM doesnt do it for the sole reason of reliablity. It is alot easier, and cost effective for a manufacturer to design a cast then to design a tubular manifold.

Cast can crack just as easy as tubular. Iv seen many cast manifolds crack on completely stock nonturbo cars/trucks. Even my greddy manifolds cracked. Proper design still plays a big role in reliability.

With that said I think both can be a very viable option, but would rather have a properly designed tubular manifold (personal choice).

Cast can crack just as easy as tubular. Iv seen many cast manifolds crack on completely stock nonturbo cars/trucks. Even my greddy manifolds cracked. Proper design still plays a big role in reliability.

With that said I think both can be a very viable option, but would rather have a properly designed tubular manifold (personal choice).

I can agree with your statement, Although I would rather have a cast manifold, just because of issues some of my personal friends have had with tubular manifolds.

We will have to agree to disagree

Thanks for your input!

-George

GT Motorsports

#16

Vendor - Former Vendor

iTrader: (27)

To me, a quality tubular manifold is the ticket for aftermarket performance applications. Cast manifolds definitely make sense for OEM packaging and to keep costs down, but when we are trying to squeeze power out of these cars it makes sense to go with a tubular setup. The downside in my opinion, is the additional time to fabricate them (which translates to cost) and the tubular manifold taking up more space and forcing the turbos down low... which then requires an oil scavenging system with pump etc.

Regarding cracking... I've had the Greddy and APS cast manifolds both in here with cracks. It is not extremely common, but neither is it on a properly built tubular manifold.

Regarding cracking... I've had the Greddy and APS cast manifolds both in here with cracks. It is not extremely common, but neither is it on a properly built tubular manifold.

#17

Registered User

Join Date: Dec 2007

Location: Valrico, FL

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

I have experience cracked cast turbo manifolds (one of the more commonly available 350Z turbo kits -remaining anomymous). The cracked manifolds was due to repeated uneven high temp heat cycles. To monitor this situation before it becomes catastrophic; its best to add a heat (periometer sp?) in the exhaust manifold IMHO.

Also, not all cast manifolds nor tubular exhaust manifolds are created equal. SFR have made their tubular exhaust manifolds for the 350Z available for several years. GTM has made their cast exhaust manifold for a few years.

Additionally, the 350Z engine bay is tight - one of the reasons Nissan decided not to offer a turbo kit for the current Z platform.

I am not aware if the available turbo kits can be retro-fitted from a cast manifold to a tubular manifold and still be able to operate as designed. I sure SFR,GTM,SP,SPS can response.

It is best to inquiry on the end users that seriously track their Z to make an informative decision on pulling the purchase trigger.

Good luck in your search!

Also, not all cast manifolds nor tubular exhaust manifolds are created equal. SFR have made their tubular exhaust manifolds for the 350Z available for several years. GTM has made their cast exhaust manifold for a few years.

Additionally, the 350Z engine bay is tight - one of the reasons Nissan decided not to offer a turbo kit for the current Z platform.

I am not aware if the available turbo kits can be retro-fitted from a cast manifold to a tubular manifold and still be able to operate as designed. I sure SFR,GTM,SP,SPS can response.

It is best to inquiry on the end users that seriously track their Z to make an informative decision on pulling the purchase trigger.

Good luck in your search!

Last edited by 35Z; 02-04-2009 at 04:07 PM. Reason: spelling & grammer

#20

Registered User

iTrader: (4)

Join Date: Apr 2005

Location: CA

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

http://www.turbobygarrett.com/turbob...tech102.html#c <---- good article on this subject. and w/ a bit more reading on that site will answer questions you may not even have yet.