No, I'm not going to turbocharge it... My TT G35.

#81

ya cylinder wash is super rich. my idle was 11-11.5, but my latency's werent right so i think when i spend more time, high 13's will be ok, esp since i'll be idling much higher and base FP much lower.

474LPH for both pumps at 13.8V @70psi? Thats right on par with the Walbro 342 fuel curves. Thats enough to support 1200cc injectors at 70psi fuel pressure. Be interesting to see where you run out of pump on E85. probably 800DJ

474LPH for both pumps at 13.8V @70psi? Thats right on par with the Walbro 342 fuel curves. Thats enough to support 1200cc injectors at 70psi fuel pressure. Be interesting to see where you run out of pump on E85. probably 800DJ

I haven't had much time to work with it. Cold, warm, and hot start are good. Transient throttle is good. Idle still needs attention though it's not that bad, just a bit rich.

I did go for a short drive and even stood on the throttle. Light load needs cleaned up and she's way rich up top but it was cool to see <30% injector duty cycle at a boost level where the car made ~500WHP.

I expect to be able to get a solid 12.5-13.0AFR at idle with the current fuel pressure, which should be ok. I did a bit of research on bore wash and it does not seem to be a concern until the low 10AFRs or even more rich. Since these injectors are touted for their atomization, I'm confident I won't hurt the engine.

I did run a few fuel system tests at various pressures. Of note is at 13.8V, my Walbro 255HP's pushed 474LPH of fuel to the engine compartment at 70psi. Unfortunately, I didn't have a good way to keep voltage stable while turning the pressure up, so I feel some of the flow loss at higher pressures are a result of dropping voltage. I have the Walbro relief valves disabled. With the car running the pumps get a steady 14-14.1V. I was already using gasoline as a test fluid, I wasn't brave enough to do it with the engine running.

I have tests showing 40, 50, 60, and 70psi with the battery charger on the low setting, and 50, 60, 70, 80, and 90 with it on the high setting. As I mentioned, without a good regulating power supply, as pressure goes up, voltage goes down and flow does as well, as expected.

I did go for a short drive and even stood on the throttle. Light load needs cleaned up and she's way rich up top but it was cool to see <30% injector duty cycle at a boost level where the car made ~500WHP.

I expect to be able to get a solid 12.5-13.0AFR at idle with the current fuel pressure, which should be ok. I did a bit of research on bore wash and it does not seem to be a concern until the low 10AFRs or even more rich. Since these injectors are touted for their atomization, I'm confident I won't hurt the engine.

I did run a few fuel system tests at various pressures. Of note is at 13.8V, my Walbro 255HP's pushed 474LPH of fuel to the engine compartment at 70psi. Unfortunately, I didn't have a good way to keep voltage stable while turning the pressure up, so I feel some of the flow loss at higher pressures are a result of dropping voltage. I have the Walbro relief valves disabled. With the car running the pumps get a steady 14-14.1V. I was already using gasoline as a test fluid, I wasn't brave enough to do it with the engine running.

I have tests showing 40, 50, 60, and 70psi with the battery charger on the low setting, and 50, 60, 70, 80, and 90 with it on the high setting. As I mentioned, without a good regulating power supply, as pressure goes up, voltage goes down and flow does as well, as expected.

#83

Missed the last few updates - nicely done. Now that you have a Haltech, I would consider dialing in the dwell time on the dyno and/or regapping copper plugs and then repurposing the boost-a-spark as a boost-a-pump.

http://www.tonyfoale.com/Articles/Ignition/Ignition.htm

http://www.tonyfoale.com/Articles/Ignition/Ignition.htm

#84

Thread Starter

New Member

iTrader: (7)

Joined: Apr 2007

Posts: 211

Likes: 0

From: York County, Pennsylvania.

Update this a bit.

Let's wake this one back up. I've collected a few parts over the past month. I'm still waiting for the cams to show up.

I picked up a Fluidampr from a local, a brand new set of Supertech dual valve springs and Ti retainers, and the Kelford 288/288 cams are in the mail. I also plan to switch over to the VQ35HR cam follower buckets as I'm probably going to have to replace a few to get the valve clearances in check, and the newer parts are DLC (diamond like coating) covered to reduce friction.

Let's wake this one back up. I've collected a few parts over the past month. I'm still waiting for the cams to show up.

I picked up a Fluidampr from a local, a brand new set of Supertech dual valve springs and Ti retainers, and the Kelford 288/288 cams are in the mail. I also plan to switch over to the VQ35HR cam follower buckets as I'm probably going to have to replace a few to get the valve clearances in check, and the newer parts are DLC (diamond like coating) covered to reduce friction.

#85

Thread Starter

New Member

iTrader: (7)

Joined: Apr 2007

Posts: 211

Likes: 0

From: York County, Pennsylvania.

I've been back into this car, the camshaft install is in process. Cams are Kelford 288's. I'm also installing the Super Tech dual valve springs and cleaning up some stuff. Under the hood.

I purchased the on the car valve spring compressor from JWT. I used compressed air to hold the valves closed while replacing the springs and valve seals. The JWT tool worked well, though the plastic thumb wheels became a pain. I removed them and used a ratchet and socket to run the compressor screws in.

Start.

Front of the engine all apart.

Opened up.

Replacing the valve springs.

Old springs vs. new. I didn't expect the factory spring retainers to be aluminum. I guess I'm behind the times. The old springs are babies strength wise to the new ones. I think she'll rev out a bit more.

I purchased the on the car valve spring compressor from JWT. I used compressed air to hold the valves closed while replacing the springs and valve seals. The JWT tool worked well, though the plastic thumb wheels became a pain. I removed them and used a ratchet and socket to run the compressor screws in.

Start.

Front of the engine all apart.

Opened up.

Replacing the valve springs.

Old springs vs. new. I didn't expect the factory spring retainers to be aluminum. I guess I'm behind the times. The old springs are babies strength wise to the new ones. I think she'll rev out a bit more.

#86

Thread Starter

New Member

iTrader: (7)

Joined: Apr 2007

Posts: 211

Likes: 0

From: York County, Pennsylvania.

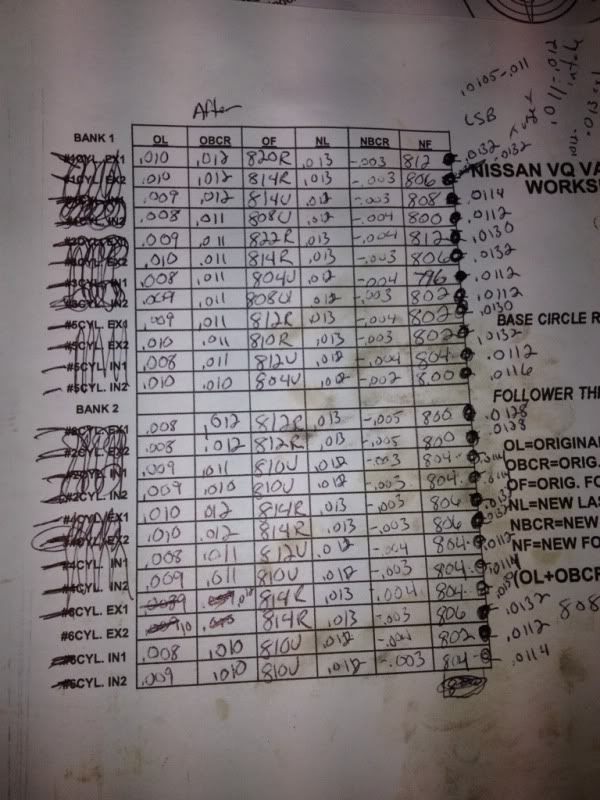

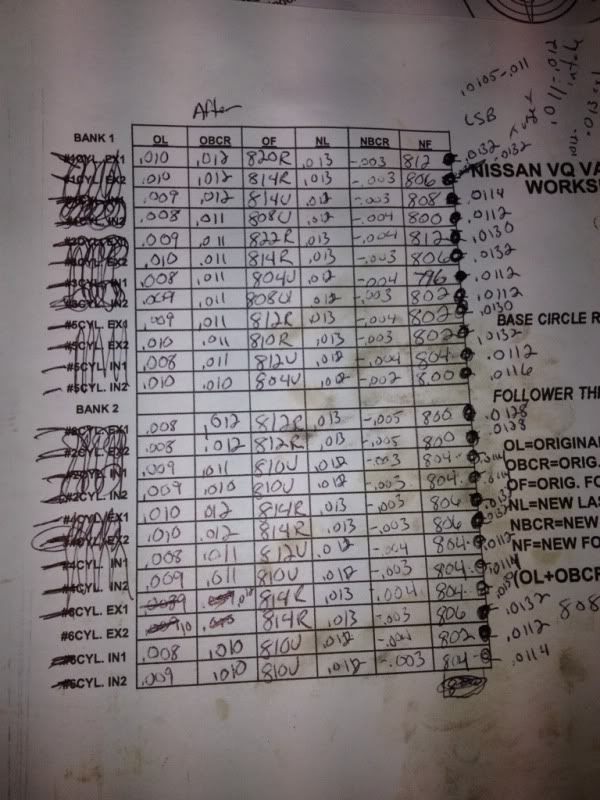

I finally received my lash buckets from Nissan.

The buckets are in, cam lash was checked with the new parts, assembly lube smeared about, and cams installed. I hope to have it running next weekend.

New lifters.

Old polished vs. DLC.

Lash worksheet.

The buckets are in, cam lash was checked with the new parts, assembly lube smeared about, and cams installed. I hope to have it running next weekend.

New lifters.

Old polished vs. DLC.

Lash worksheet.

#87

Thread Starter

New Member

iTrader: (7)

Joined: Apr 2007

Posts: 211

Likes: 0

From: York County, Pennsylvania.

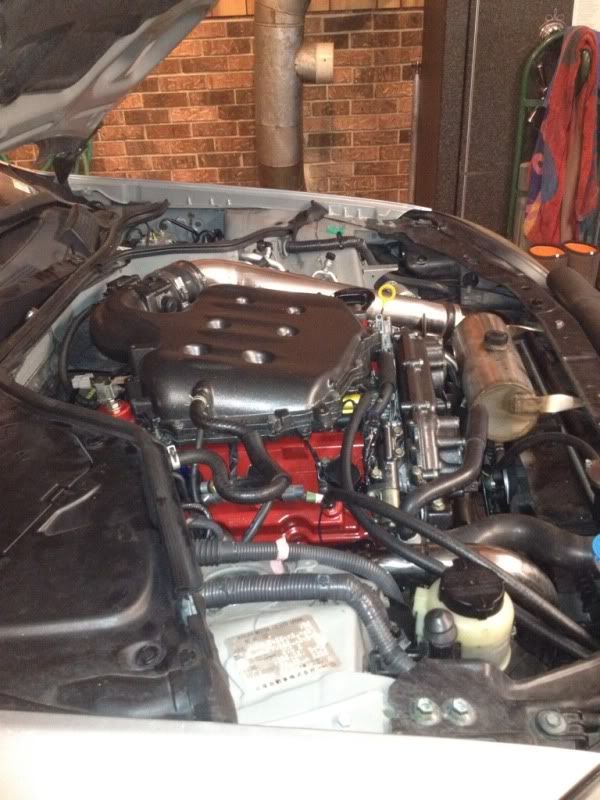

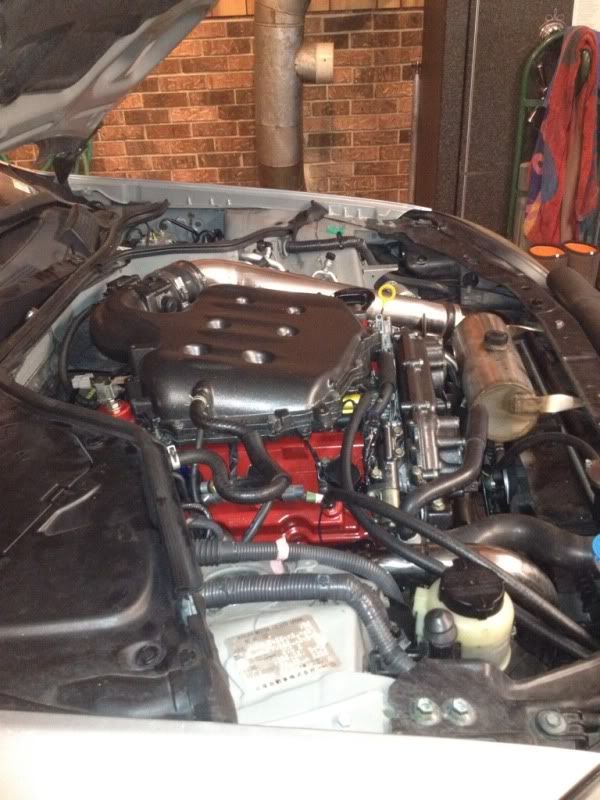

Got this running last night. It sounds neat, now I just need to get it aligned and then it's time to try it out.

Video.

http://www.youtube.com/watch?v=4WHT4...e_gdata_player

I finally painted the front cover.

Video.

http://www.youtube.com/watch?v=4WHT4...e_gdata_player

I finally painted the front cover.

#88

Thread Starter

New Member

iTrader: (7)

Joined: Apr 2007

Posts: 211

Likes: 0

From: York County, Pennsylvania.

I also added SPL solid rear diff mounts, compression rod bearings, and lower control arm bearings, SPC camber arms and toe bolts, and a braided clutch line. Installing the diff bushings was a breeze with a bottle of liquid N2O in the garage.

Idle and driveability isn't near as bad as I expected. I'd have to look at the logs, but I even think the boost comes on faster. The car surely pulls harder up top, no more laying over just above 6000RPM.

I have to get it back on the dyno and see what the power difference is at wastegate boost.

Oh and the proper alignment of the rear wheels and the solid diff mounts made a world of difference in how the car hooks, and reduced wheel hop to almost nothing.

Idle and driveability isn't near as bad as I expected. I'd have to look at the logs, but I even think the boost comes on faster. The car surely pulls harder up top, no more laying over just above 6000RPM.

I have to get it back on the dyno and see what the power difference is at wastegate boost.

Oh and the proper alignment of the rear wheels and the solid diff mounts made a world of difference in how the car hooks, and reduced wheel hop to almost nothing.

Thread

Thread Starter

Forum

Replies

Last Post

EnjukuRacing

Engine

0

09-11-2015 09:30 AM