rough comparison of exhaust flow % vs pipe diameter

#1

I'm getting a new exhaust and was curious roughly how much more it'd flow so I did some calculations of the different diameter exhausts. It's a rough estimate that ONLY factors in diameter of pipes because you can't really factor in different types of mufflers, types of bends, flex pipes, etc. There's other crap at work too like turbulence and how fast different diameter pipes cool off.

This is just an area of the pipe comparison

The image attached shows a % comparison bar graph as well as taking the dual exhausts and converting them into the equivalent single exhausts just for a better visual comparison than trying to imagine how the duals compare to the singles

using area of a circle = Pi x (radius x radius)

where Pi = 3.14 rounded

stock, 60mm = 2.3622 inch diameter

Pi x 1.1811 x 1.1811 = 4.38029 sq inches

100% area to flow through

single 3 inch

Pi x 1.5 x 1.5 = 7.065

1.6129 times more area to flow through than stock

dual 2.25 inch

Pi x 1.125 x 1.125 = 3.9740625 x 2 pipes = 7.948125

equivalent flow to a single 3.18198 inch exhaust

1.8145 times more area to flow through than stock

dual 60mm (stillen, not graphed)

2 times more area to flow through than stock

dual 2.5 inch

Pi x 1.25 x 1.25 = 4.90625 x 2 pipes = 9.8125

equivalent flow to a single 3.53553 inch exhaust

2.2401 times more area to flow through than stock

dual 2.75 inch

Pi x 1.375 x 1.375 = 5.9365625 x 2 pipes = 11.873125

equivalent flow to a single 3.889 inch exhaust

2.7105 times more area to flow through than stock

dual 3 inch

Pi x 1.5 x 1.5 = 7.065 x 2 pipes = 14.13

equivalent flow a single 4.2426 inch exhaust

3.2258 times more area to flow through than stock

This is just an area of the pipe comparison

The image attached shows a % comparison bar graph as well as taking the dual exhausts and converting them into the equivalent single exhausts just for a better visual comparison than trying to imagine how the duals compare to the singles

using area of a circle = Pi x (radius x radius)

where Pi = 3.14 rounded

stock, 60mm = 2.3622 inch diameter

Pi x 1.1811 x 1.1811 = 4.38029 sq inches

100% area to flow through

single 3 inch

Pi x 1.5 x 1.5 = 7.065

1.6129 times more area to flow through than stock

dual 2.25 inch

Pi x 1.125 x 1.125 = 3.9740625 x 2 pipes = 7.948125

equivalent flow to a single 3.18198 inch exhaust

1.8145 times more area to flow through than stock

dual 60mm (stillen, not graphed)

2 times more area to flow through than stock

dual 2.5 inch

Pi x 1.25 x 1.25 = 4.90625 x 2 pipes = 9.8125

equivalent flow to a single 3.53553 inch exhaust

2.2401 times more area to flow through than stock

dual 2.75 inch

Pi x 1.375 x 1.375 = 5.9365625 x 2 pipes = 11.873125

equivalent flow to a single 3.889 inch exhaust

2.7105 times more area to flow through than stock

dual 3 inch

Pi x 1.5 x 1.5 = 7.065 x 2 pipes = 14.13

equivalent flow a single 4.2426 inch exhaust

3.2258 times more area to flow through than stock

Last edited by sentry65; 01-19-2007 at 02:24 AM.

#3

Registered User

iTrader: (24)

Join Date: Aug 2005

Location: NewCastle, WA

Posts: 2,947

Likes: 0

Received 0 Likes

on

0 Posts

thanks for the #'s. Understanding that you only did a quick comparison, the wetted surface area (for exhaust piping, it'd be the circumfrance) should also be taken into consideration - that's what causes the resistance. This is nessacary to bring up when comparing single vs. dual exhaust...dual might have more cross-sectional area, but they also have more circumfrance.

-Peter

-Peter

#4

yeah good point, that's one of those factors that just gets hard to factor in - or at least I don't know of how to calculate resistance vs circumference and put them in any sort of relationship

Mainly I'm just showing the relationship between the volume of air between different size piping.

So many people think a dual 2.5 exhaust is equal to a single 5 inch exhaust and it just doesn't work that way.

It's similar to how two 2.5 inch squares does not fill up the area of a single 5 inch square - it only fills up half the area.

Then it's tricky for a lot of people because most people don't remember how to find the area of a circle

Mainly I'm just showing the relationship between the volume of air between different size piping.

So many people think a dual 2.5 exhaust is equal to a single 5 inch exhaust and it just doesn't work that way.

It's similar to how two 2.5 inch squares does not fill up the area of a single 5 inch square - it only fills up half the area.

Then it's tricky for a lot of people because most people don't remember how to find the area of a circle

Last edited by sentry65; 01-18-2007 at 02:10 PM.

#5

How to find the area of a circle:

Good write up though- The area of a circle can be found by multiplying pi ¶ (which is equal to 3.14) by the square of the radius

- If a circle has a radius of 4, its area is 3.14*4*4=50.24

- If you know the diameter, the radius is 1/2 as large

Later

Todd

#6

Registered User

iTrader: (24)

Join Date: Aug 2005

Location: NewCastle, WA

Posts: 2,947

Likes: 0

Received 0 Likes

on

0 Posts

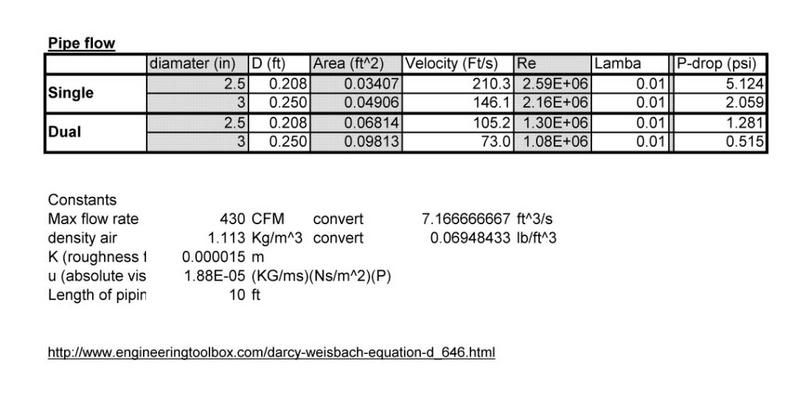

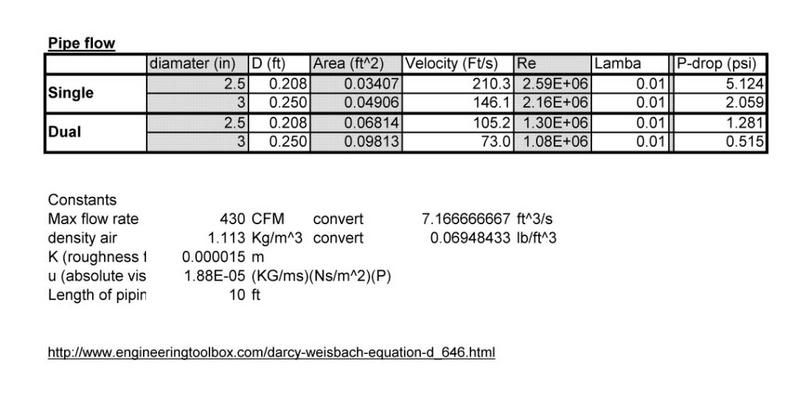

just found my old link ... I had done this about a month ago using a handful of equations to compare single vs. dual exhaust:

I'm working more and more with CFD (computational fluid dynamics) - I'm hoping to at some point do a fairly accurate analysis of either the intake or exhaust system on the Z, and to compare changes with resulting perofmance

I'm working more and more with CFD (computational fluid dynamics) - I'm hoping to at some point do a fairly accurate analysis of either the intake or exhaust system on the Z, and to compare changes with resulting perofmance

#7

Registered User

iTrader: (5)

Join Date: Dec 2005

Location: N.VA

Posts: 500

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by first350

I'm working more and more with CFD (computational fluid dynamics) - I'm hoping to at some point do a fairly accurate analysis of either the intake or exhaust system on the Z, and to compare changes with resulting perofmance

Good post btw sentry65.

Trending Topics

#8

MOTORDYNE-MY350Z SPONSOR

iTrader: (53)

Good job Sentry!

First350,

What mol. wt. and temperature did you use for your calculations?

Is Rho V^2/2g in included in the spreadsheet? It will be a substantial fraction of the total.

Originally Posted by first350

I'm working more and more with CFD (computational fluid dynamics) - I'm hoping to at some point do a fairly accurate analysis of either the intake or exhaust system on the Z, and to compare changes with resulting perofmance

What mol. wt. and temperature did you use for your calculations?

Is Rho V^2/2g in included in the spreadsheet? It will be a substantial fraction of the total.

The following users liked this post:

WVguy (05-01-2022)

#10

Registered User

iTrader: (24)

Join Date: Aug 2005

Location: NewCastle, WA

Posts: 2,947

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Hydrazine

Good job Sentry!

First350,

What mol. wt. and temperature did you use for your calculations?

Is Rho V^2/2g in included in the spreadsheet? It will be a substantial fraction of the total.

First350,

What mol. wt. and temperature did you use for your calculations?

Is Rho V^2/2g in included in the spreadsheet? It will be a substantial fraction of the total.

I ran those calculations more than a month ago ... I think i just used a flow rate from our 3.5L @ 7K rpms assuming STD pressure/temp (big source of error b/c the pressure/temp is much much greater as it exits the engine)...if/when I run some CFD modeling, I'll try to roughly introduce some heat transfer to model the exhaust gas cooling down...but work has just been too busy.

does MD do any kind of CFD analysis? I've seen some of your calcs for heat dissipation on the ISO themral gasket - always glad to see the #'s behind our mods!

-Peter

#11

MOTORDYNE-MY350Z SPONSOR

iTrader: (53)

Originally Posted by first350

does MD do any kind of CFD analysis? I've seen some of your calcs for heat dissipation on the ISO themral gasket - always glad to see the #'s behind our mods!

-Peter

-Peter

I used a true CFD modeling program when I worked at Boeing but they cost big $$$. And they were only on a lease basis.

Besides, I can do most of what I need with Excel. Excel can do all of the steady state modeling but it can't do modeling of flowing/resonating systems. It gets waaaay too tedious.

It will be easier to go by Excel guidance mixed with real trial and error on a real exhaust system.

And now that I have the resourses in house to design, build and dyno test, that's exactly what I'll be doing over the next several months.

Tony

#12

Originally Posted by Hydrazine

I do it in Excel.

I used a true CFD modeling program when I worked at Boeing but they cost big $$$. And they were only on a lease basis.

Besides, I can do most of what I need with Excel. Excel can do all of the steady state modeling but it can't do modeling of flowing/resonating systems. It gets waaaay too tedious.

It will be easier to go by Excel guidance mixed with real trial and error on a real exhaust system.

And now that I have the resourses in house to design, build and dyno test, that's exactly what I'll be doing over the next several months.

Tony

I used a true CFD modeling program when I worked at Boeing but they cost big $$$. And they were only on a lease basis.

Besides, I can do most of what I need with Excel. Excel can do all of the steady state modeling but it can't do modeling of flowing/resonating systems. It gets waaaay too tedious.

It will be easier to go by Excel guidance mixed with real trial and error on a real exhaust system.

And now that I have the resourses in house to design, build and dyno test, that's exactly what I'll be doing over the next several months.

Tony

I interviewed with Boeing for their international space station program. I was 2nd in line.

The guy they made an offer to had experience, and I just graduated in August 06 from UT with a BSME.

The guy they made an offer to had experience, and I just graduated in August 06 from UT with a BSME.

#14

Registered User

iTrader: (24)

Join Date: Aug 2005

Location: NewCastle, WA

Posts: 2,947

Likes: 0

Received 0 Likes

on

0 Posts

I work for Boeing up in the Everett, Wa. I have a BSME degree from Berkeley - my previous job I had been doing more CFD work for fire losses. fun stuff - just trying to apply more of it to cars!

-Peter

-Peter

Originally Posted by Hydrazine

I do it in Excel.

I used a true CFD modeling program when I worked at Boeing but they cost big $$$. And they were only on a lease basis.

Besides, I can do most of what I need with Excel. Excel can do all of the steady state modeling but it can't do modeling of flowing/resonating systems. It gets waaaay too tedious.

It will be easier to go by Excel guidance mixed with real trial and error on a real exhaust system.

And now that I have the resourses in house to design, build and dyno test, that's exactly what I'll be doing over the next several months.

Tony

I used a true CFD modeling program when I worked at Boeing but they cost big $$$. And they were only on a lease basis.

Besides, I can do most of what I need with Excel. Excel can do all of the steady state modeling but it can't do modeling of flowing/resonating systems. It gets waaaay too tedious.

It will be easier to go by Excel guidance mixed with real trial and error on a real exhaust system.

And now that I have the resourses in house to design, build and dyno test, that's exactly what I'll be doing over the next several months.

Tony

#15

MOTORDYNE-MY350Z SPONSOR

iTrader: (53)

Originally Posted by first350

I work for Boeing up in the Everett, Wa. I have a BSME degree from Berkeley - my previous job I had been doing more CFD work for fire losses. fun stuff - just trying to apply more of it to cars!

-Peter

-Peter

Hows it all going in Boeing Wa.? Everything busier these days? What do people say about Airbus these days? Any loptops with employees personal records stolen lately? JK

Yeah, its good to know that we can actually use all (er some) of that stuff we learned in College/work for fun stuff too.

#16

Retired Admin

iTrader: (95)

So explain this all to us average joes.. Does/should the true dual exhausts like the HKS or Injen (don't know diameter sizes) better than the stock in all RPMs? Or is it like my old exhaust, Top Speed Pro-1, where it lost low-end torque due to its 3" diameter piping, but made up for in top end? What is the optimal pipe size and/or type (single exit, true dual, y-pipe at muffler, etc) for NA (up to 300whp)? TIA

#17

Registered User

iTrader: (24)

Join Date: Aug 2005

Location: NewCastle, WA

Posts: 2,947

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 3hree5ive0ero

So explain this all to us average joes.. Does/should the true dual exhausts like the HKS or Injen (don't know diameter sizes) better than the stock in all RPMs? Or is it like my old exhaust, Top Speed Pro-1, where it lost low-end torque due to its 3" diameter piping, but made up for in top end? What is the optimal pipe size and/or type (single exit, true dual, y-pipe at muffler, etc) for NA (up to 300whp)? TIA

just comparing flow rates vs. restriction, bigger is better...but since this also involves an engine, other factors are in play.

1) Exhaust restriction: the more restrictive an exhaust is, the more amount of force the engine needs to use to 'push' the exhuast out (ie. try blowing through a coffee straw, then a normal straw...one take more energy to blow the same amount of volume out).

2) Scavenging affect: As the exhaust valve opens and closes, the exhaust gases flow out and into the header. If you have a smaller diameter header, the exhaust gases will have a larger velocity (flow rate = Velocity*Cross-sectional area)...higher velocities increase the exhaust momentum and actually help to remove a greater % of the exhaust from the cylinder. (since the piston does not go ALL the way up to the valve, there's some amount of volume at the top that is not displaced by the piston...the remaining amount of exhaust in the cylinder will lessen the performance of the following combustion cycle). So, a smaller diameter header is better for exhaust scavenging.

*low RPM: velocities are lower, so exhaust restrictions are not that high...this would area of the RPM curve can benefiet greater from a smaller diameter header b/c it will help with exhaust scavenging effects

*high RPM: Velocities are high, so exhaust restrictions go up...this area can benifiet from a more free flowing exhaust.

So you need to find the right balance between the 2. this will depend on your application: driving (street vs. racing), engine (displacment, max RPM,...)...

that's kind of it in a nutshell (or at least my nutshell)

-Peter

#18

as far as I know, going with an exhaust that's too big will almost always lose some low end power and make more high end power - as long as you are making enough power to put it to use.

It's possible to have an exhaust that's just way too big

If you put a 5 inch exhaust on a 50hp geo metro, it'd lose a crapload of power everywhere, even up high

It's possible to have an exhaust that's just way too big

If you put a 5 inch exhaust on a 50hp geo metro, it'd lose a crapload of power everywhere, even up high

#19

Retired Admin

iTrader: (95)

first350, thanks a lot for that explanation. That's basically what I thought (somebody gave me the jist of this a while back and I was just confirming). For racing, more straightline than others, what's would be the better choice - slightly large diameter (sacrifice down low but gain up top) or good size diameter (balance between the low end and top end)? Keep in mind, for straightline, you'd be in higher rpms for the most part.

Thread

Thread Starter

Forum

Replies

Last Post

Justin100

Intake Exhaust

26

11-29-2015 03:58 PM