Keeping Endlinks Tight

#1

Registered User

Thread Starter

iTrader: (1)

Join Date: Feb 2008

Location: New England

Posts: 588

Likes: 0

Received 0 Likes

on

0 Posts

I recently changed my sway bars to the hotchkis sways, and when I first put them on there was a clunk that turned out to be a loose end link. I fixed it and it went away, only to return over the last few days. I torqued it to spec, but apparently that is not good enough. Without spending a few hundred on new end links does anyone have a solution to keep them tight?

Thanks

Thanks

Last edited by =Cerberus=; 05-12-2010 at 09:27 AM.

#2

Try some blue locktite on the threads.

I think the real problem is that the paint on new sways is rather thick and slick. After a while, especially if you remove them endlinks a couple of times, the paint under the nut wears off and you now tighten it directly onto metal so it will hold better.

I think the real problem is that the paint on new sways is rather thick and slick. After a while, especially if you remove them endlinks a couple of times, the paint under the nut wears off and you now tighten it directly onto metal so it will hold better.

#6

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

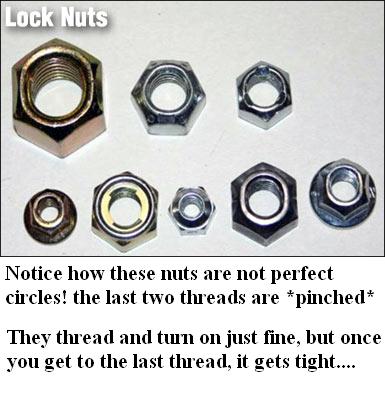

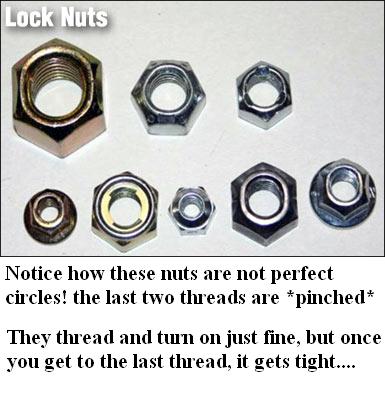

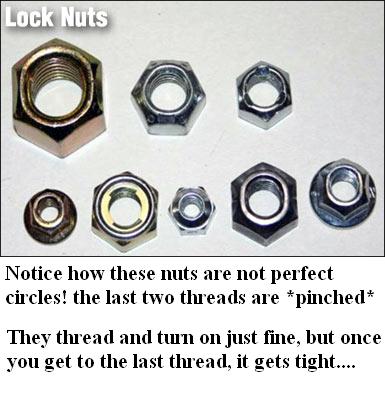

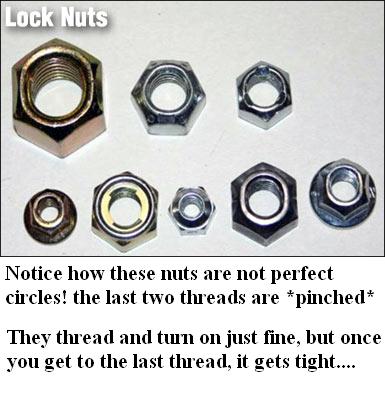

Go to a good hardware store and look for Prevailing torque lock nuts.

M12x1.25 is the stock threading.........they are hard to find...

If you look close at them, the top threads (ie, the last TWO thread when tightening) are "pinched" and those nuts hold torque spec quite well.

I use them on my car and my endlinks and have zero issues..

here they are:

-J

M12x1.25 is the stock threading.........they are hard to find...

If you look close at them, the top threads (ie, the last TWO thread when tightening) are "pinched" and those nuts hold torque spec quite well.

I use them on my car and my endlinks and have zero issues..

here they are:

-J

Last edited by JasonZ-YA; 05-12-2010 at 10:56 AM.

#7

Registered User

iTrader: (3)

Join Date: May 2009

Location: earth

Posts: 1,365

Likes: 0

Received 0 Likes

on

0 Posts

yea, i have the same thing with the lca one, mainly the drivers side. you really gotta tighten them down. ive got the red locktite on mine and it seems to be working better, just something to check each time im changing oil

Trending Topics

#8

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

I would also like to say, MOST of the factory nuts used on the Z's suspension are like what i provided (if you physically look at them you can see 4 flat spots on the top of the nuts for the "pinches").........

and most are noted that when you remove, have to be replaced........you can see that in the FSM (factory service manual) schematics due to that very reason......

-J

and most are noted that when you remove, have to be replaced........you can see that in the FSM (factory service manual) schematics due to that very reason......

-J

Last edited by JasonZ-YA; 05-12-2010 at 11:02 AM.

#9

This is the one time where I say "damn the FSM torque specs". I've been tightening them as tight as I can get with a foot long box end wrench while under the car. Mine lasted about a year before one started clicking over bumps so I went back and it was ever-so-slightly loose.

Locktite probably helps a little as the nuts are already nyloc-style. An issue I see with aftermarket over OEM is that the studs are significantly smaller than the hole in the swaybar or LCA. That little bit of play in the system seems to allow the nut to work loose after a while. Unfortunately, none of the studs are long enough to get a lock washer under the nut either.

One thing I do like about almost everything OEM is the flanged nuts they use, they have ridges on the face to act as a "lock" plus the flanged face gives a larger surface area to grab on.

Locktite probably helps a little as the nuts are already nyloc-style. An issue I see with aftermarket over OEM is that the studs are significantly smaller than the hole in the swaybar or LCA. That little bit of play in the system seems to allow the nut to work loose after a while. Unfortunately, none of the studs are long enough to get a lock washer under the nut either.

One thing I do like about almost everything OEM is the flanged nuts they use, they have ridges on the face to act as a "lock" plus the flanged face gives a larger surface area to grab on.

Last edited by DavesZ#3; 05-12-2010 at 03:48 PM.

#10

Registered User

Thread Starter

iTrader: (1)

Join Date: Feb 2008

Location: New England

Posts: 588

Likes: 0

Received 0 Likes

on

0 Posts

I had thought about the blue locktite and the lock nuts, I think it is just hard to get the nuts tight with that bracket bent out of the way.

I have a fastenal right down the street from me, so if they do not stock it, I can get it in a few days. I will probably just try and make some with hiem joints and a proper sized bolt.

I have a fastenal right down the street from me, so if they do not stock it, I can get it in a few days. I will probably just try and make some with hiem joints and a proper sized bolt.

#11

New Member

iTrader: (41)

Mine have the same problem. Wonder if sanding off the paint on the Hotchkis sways would help. Blue loctite seems to do little good.

Jason, would it be possible for you to buy some the next time you see them?

I've had problems finding what I need the last few times I've gone to my local hardware store.

Go to a good hardware store and look for Prevailing torque lock nuts.

M12x1.25 is the stock threading.........they are hard to find...

If you look close at them, the top threads (ie, the last TWO thread when tightening) are "pinched" and those nuts hold torque spec quite well.

I use them on my car and my endlinks and have zero issues..

here they are:

-J

M12x1.25 is the stock threading.........they are hard to find...

If you look close at them, the top threads (ie, the last TWO thread when tightening) are "pinched" and those nuts hold torque spec quite well.

I use them on my car and my endlinks and have zero issues..

here they are:

-J

I've had problems finding what I need the last few times I've gone to my local hardware store.

#15

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

Nylon wont work......I know some that have slipped.......like i said, its hard to source.....ones like the pic i posted.........

but i thought i gave the answer to finding some prevailing torque M12x1.25 on post #8.....

Here ya go:

http://www.courtesyparts.com/350z-pa...5_800_804.html

Nut 55269:

http://www.courtesyparts.com/55269-n...8-p-15837.html

Nut 55269a:

http://www.courtesyparts.com/55269a-...8-p-15839.html

-J

but i thought i gave the answer to finding some prevailing torque M12x1.25 on post #8.....

Here ya go:

http://www.courtesyparts.com/350z-pa...5_800_804.html

Nut 55269:

http://www.courtesyparts.com/55269-n...8-p-15837.html

Nut 55269a:

http://www.courtesyparts.com/55269a-...8-p-15839.html

-J

Last edited by JasonZ-YA; 05-12-2010 at 07:45 PM.

#19

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

I realize the OP has stock endlinks......

However, with some aftermarket end links you can switch out the hardware.....

like dave mentioned above, some sway bars have thick powdercoats on them, sadly the aftermarket companies purposely do this knowing that stock endlink bolts are M12 diameter............SOOOoooo........what they do is drill 1/2 holes in their sway bars and then use thick poweder coat and call it good........

i have also seen some use 31/64 holes, then powder coat, but whatever..

I have personally reamed sway bars and used 1/2 hardware with prevailing torque lock nuts, then USING AFTERMARKET ENDLINKS..and seen people ream the lower translink arm to 1/2" with certain endlinks..

I have also used endlinks with M12x1.75 bolts top and bottom and have reamed out the sway bar holes to 5/8" and inserted a machined bushing/sleeve with an M12 hole, nitrogen frozen press fit on the sway bar and then on the lower control arm side used M12x1.75 bolts and prevailing torque nuts, as i don't want to ream the lower control arm hole.....

TO OP:

Is this your cool street car with sway bars and end links or a track car???? many options to solve this problem......ya just gotta decide....

Crap like this is why i make my own stuff.......

-J

However, with some aftermarket end links you can switch out the hardware.....

like dave mentioned above, some sway bars have thick powdercoats on them, sadly the aftermarket companies purposely do this knowing that stock endlink bolts are M12 diameter............SOOOoooo........what they do is drill 1/2 holes in their sway bars and then use thick poweder coat and call it good........

i have also seen some use 31/64 holes, then powder coat, but whatever..

I have personally reamed sway bars and used 1/2 hardware with prevailing torque lock nuts, then USING AFTERMARKET ENDLINKS..and seen people ream the lower translink arm to 1/2" with certain endlinks..

I have also used endlinks with M12x1.75 bolts top and bottom and have reamed out the sway bar holes to 5/8" and inserted a machined bushing/sleeve with an M12 hole, nitrogen frozen press fit on the sway bar and then on the lower control arm side used M12x1.75 bolts and prevailing torque nuts, as i don't want to ream the lower control arm hole.....

TO OP:

Is this your cool street car with sway bars and end links or a track car???? many options to solve this problem......ya just gotta decide....

Crap like this is why i make my own stuff.......

-J

Last edited by JasonZ-YA; 05-13-2010 at 03:45 AM.

#20

350Z-holic

iTrader: (60)

Join Date: Jan 2006

Location: San Antonio/I miss DFW, TX

Posts: 11,204

Likes: 0

Received 28 Likes

on

19 Posts

if you look at the FSM pic above, you will see that the end link bolt doesn't have the symbol of a CIRCLE WITH AN "X" IN IT...............

Then locate that bolt at courtesy you will see that:

http://www.courtesyparts.com/0891834...8-p-15885.html

up, not a prevailing torque....

Like the OP mentioned, he didn't have this problem till AFTER he got sway bars.....

-J

Last edited by JasonZ-YA; 05-12-2010 at 07:59 PM.