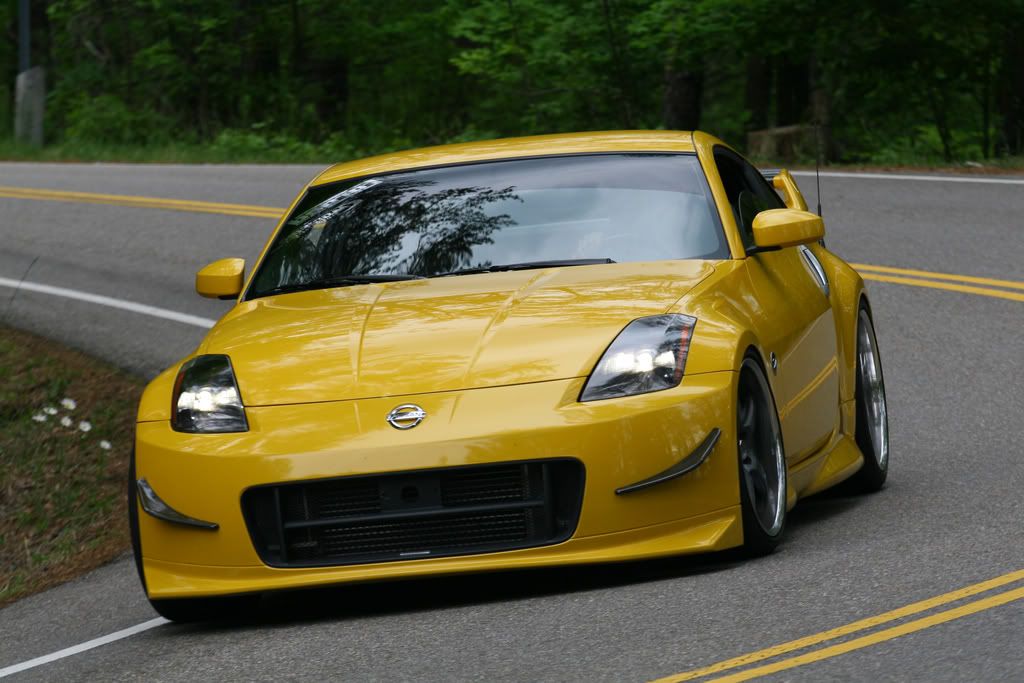

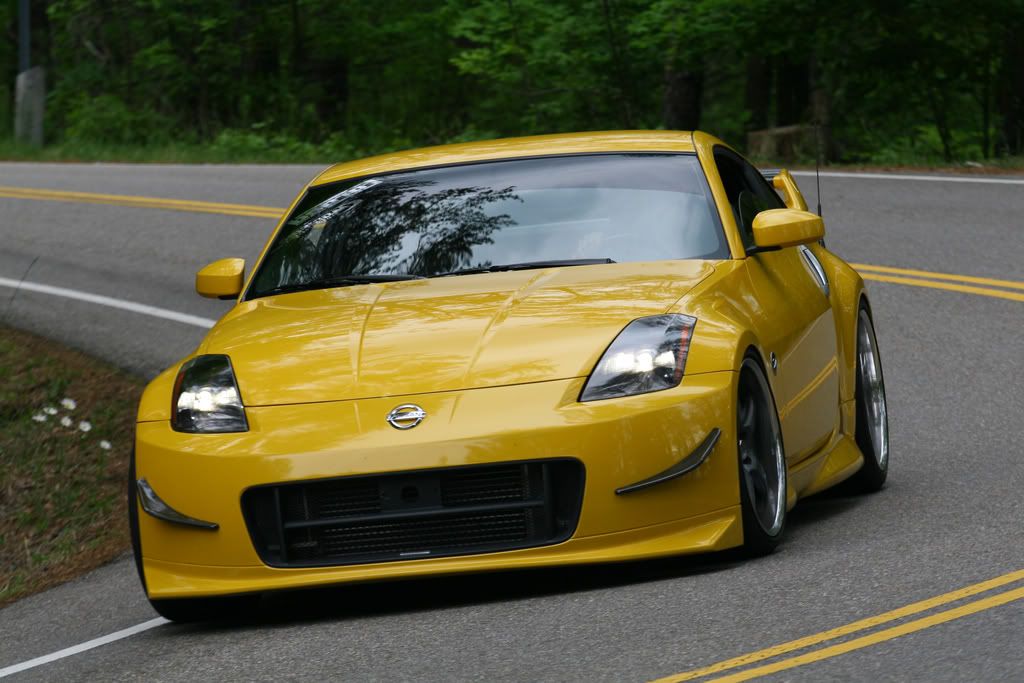

--->jkenefic version 3.0 build<---

#1

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: Indianapolis, IN

Posts: 423

Likes: 0

Received 0 Likes

on

0 Posts

Well I wanted to wait a while to post the results of the engine rebuild to make sure that the parts I used were going to hold up to the power levels I was after..... And the story goes a little something like this...

As a lot of you know I was a victim of the dreaded headlift on a sleeved motor like quite a few others on this forum. I came across a hell of a deal on a 100mm bore Darton sleeved block when my first build went due to a steam pocket in the cooling system. The deal was so good I thought "how can I pass this up?" Well 1200 miles later I should have! Heads started lifting so bad that not even wastegate spring boost would hold. Now in all fairness, I think my headlift issue was a combination of improper sleeve installation and the machine shop not resurfacing the block (checked it for straightness and left it at that). The motor made great power, but once the heads started lifting and after talking to several other people with the same issues I decided to start over with a new core block.

After many hours of research on torque to yield bolts and talking to the few true experts in the VQ community I decided on the following short block build:

-----------------------------------------------------------------------------

-Forged Performance Arias 9.0 Extreme Duty Pistons .020" overbore

-Eagle Rods

-Revup Oil Pump

-ARP Main Studs

-STOCK VQ35HR HEAD BOLTS

-STOCK VQ35HR HEAD GASKETS

-Evans NPG Coolant

-----------------------------------------------------------------------------

Everything else was from the original build:

-Cosworth Heads

-JWT C2 Cams

-Revup lower intake manifold w/ Crawford upper

-AMS Radiator

-Greddy Coolant Expansion Tank

-Custom Oil Cooler

-ATS Triple Disk Clutch

-HKS FCon VPro

-HKS EVC 6

-HKS AFK

-AlkyControl jkenefic spec meth kit

Only other change that was made was the turbo upgrade to the 20Gs thanks to Mr. Mike Edens!

When I told Sharif that I was going to do this build he thought I was nuts And to be honest so did I! So with just 20 days left before ZDayZ I got started on pulling the engine and 13 days later I was ready for tuning!!

And to be honest so did I! So with just 20 days left before ZDayZ I got started on pulling the engine and 13 days later I was ready for tuning!!

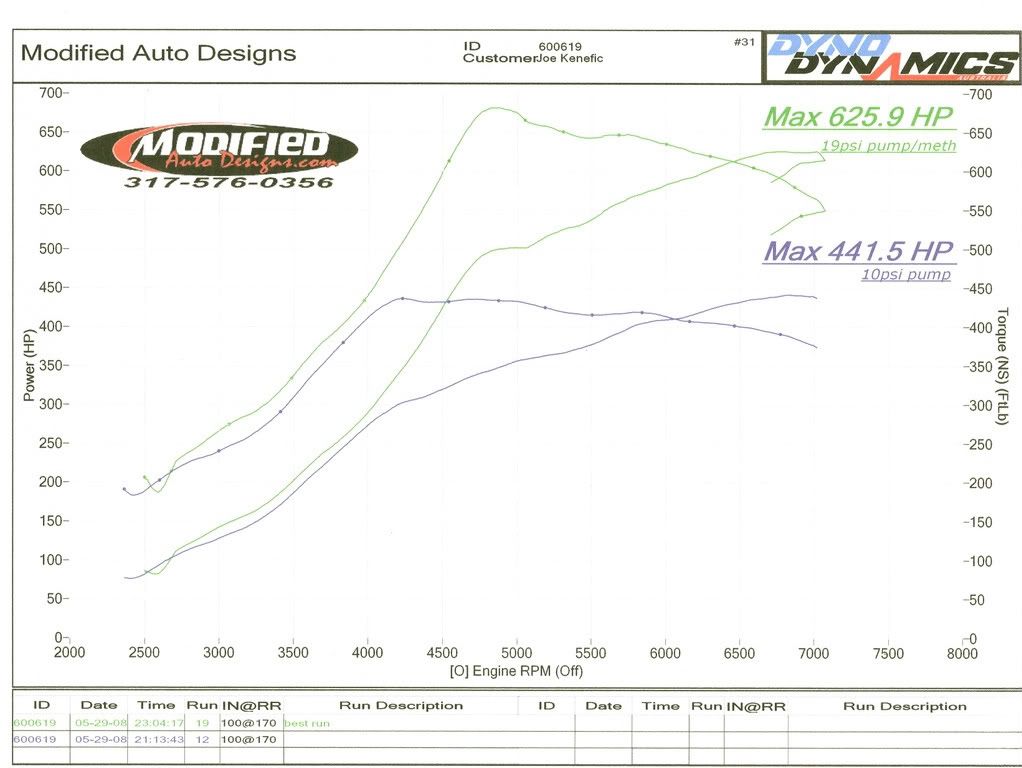

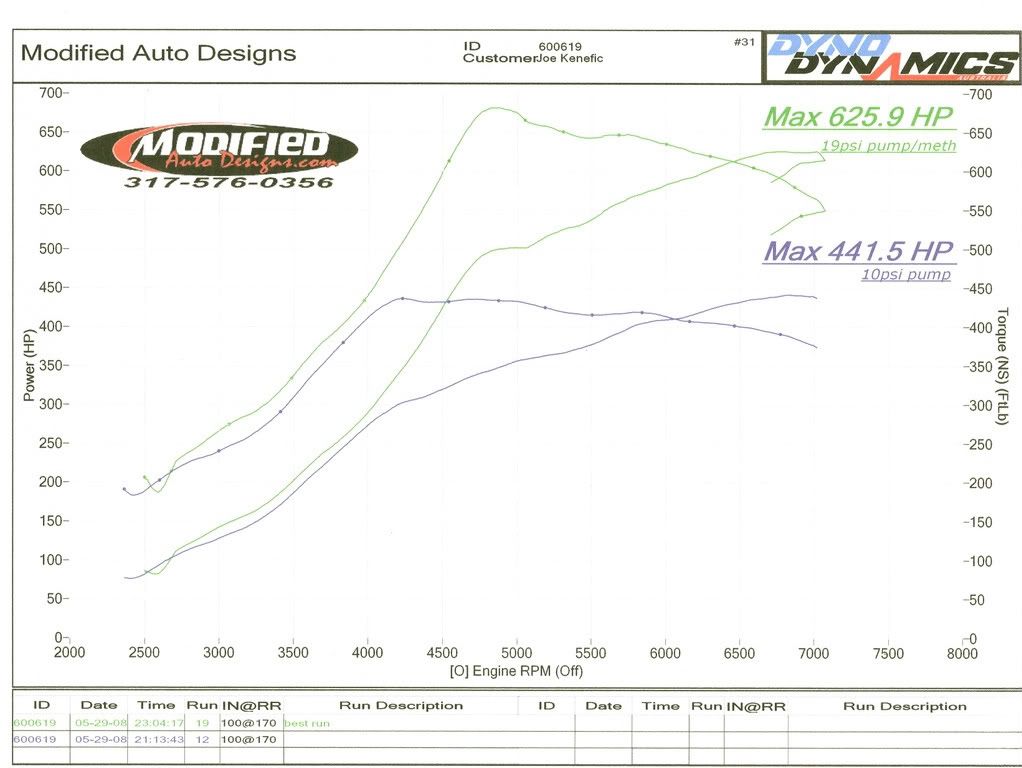

At this point I was not going to let this freaking car beat me. So after much debate, Sharif and I decided to give it a go and see if the myth of the STOCK HEAD BOLTS was real or not. Only slight modification was needed to the DE block to use the HR head gaskets. The HR gaskets redirect the coolant flow around the exhaust ports which is a far better design for FI application. IMO, these gaskets are the best thing available for a build on the market including the HKS. I am happy to report that Jim Wolf knows what the heck he is talking about. Sharif pulled no punches on the tuning and we are making awesome power on the dyno with pump gas and methanol. The only reason we stopped tuning was this is all the power a single Walbro 255 will support. The true test will be the longevity of this build, but so far so good... 45+ dyno pulls, ZDayZ, and some "airstrip" runs later and absolutely no signs of head lift! I do not have the dyno charts from Forged Performance, but I recently dynoed the car at my shop in Indy and the numbers are virtually identical to what we saw in GA.

Next step... figure out how to put this power to the ground and run a good time in the 1320.

As a lot of you know I was a victim of the dreaded headlift on a sleeved motor like quite a few others on this forum. I came across a hell of a deal on a 100mm bore Darton sleeved block when my first build went due to a steam pocket in the cooling system. The deal was so good I thought "how can I pass this up?" Well 1200 miles later I should have! Heads started lifting so bad that not even wastegate spring boost would hold. Now in all fairness, I think my headlift issue was a combination of improper sleeve installation and the machine shop not resurfacing the block (checked it for straightness and left it at that). The motor made great power, but once the heads started lifting and after talking to several other people with the same issues I decided to start over with a new core block.

After many hours of research on torque to yield bolts and talking to the few true experts in the VQ community I decided on the following short block build:

-----------------------------------------------------------------------------

-Forged Performance Arias 9.0 Extreme Duty Pistons .020" overbore

-Eagle Rods

-Revup Oil Pump

-ARP Main Studs

-STOCK VQ35HR HEAD BOLTS

-STOCK VQ35HR HEAD GASKETS

-Evans NPG Coolant

-----------------------------------------------------------------------------

Everything else was from the original build:

-Cosworth Heads

-JWT C2 Cams

-Revup lower intake manifold w/ Crawford upper

-AMS Radiator

-Greddy Coolant Expansion Tank

-Custom Oil Cooler

-ATS Triple Disk Clutch

-HKS FCon VPro

-HKS EVC 6

-HKS AFK

-AlkyControl jkenefic spec meth kit

Only other change that was made was the turbo upgrade to the 20Gs thanks to Mr. Mike Edens!

When I told Sharif that I was going to do this build he thought I was nuts

At this point I was not going to let this freaking car beat me. So after much debate, Sharif and I decided to give it a go and see if the myth of the STOCK HEAD BOLTS was real or not. Only slight modification was needed to the DE block to use the HR head gaskets. The HR gaskets redirect the coolant flow around the exhaust ports which is a far better design for FI application. IMO, these gaskets are the best thing available for a build on the market including the HKS. I am happy to report that Jim Wolf knows what the heck he is talking about. Sharif pulled no punches on the tuning and we are making awesome power on the dyno with pump gas and methanol. The only reason we stopped tuning was this is all the power a single Walbro 255 will support. The true test will be the longevity of this build, but so far so good... 45+ dyno pulls, ZDayZ, and some "airstrip" runs later and absolutely no signs of head lift! I do not have the dyno charts from Forged Performance, but I recently dynoed the car at my shop in Indy and the numbers are virtually identical to what we saw in GA.

Next step... figure out how to put this power to the ground and run a good time in the 1320.

Last edited by MADScientist; 06-04-2008 at 05:58 PM.

#7

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: Indianapolis, IN

Posts: 423

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by thom000001

jkenefic,

Nice build and nice numbers..

Did we happen to meet at Sound Performance in April (I had the silver G35 that we were pulling the motor on)?

Tom

Nice build and nice numbers..

Did we happen to meet at Sound Performance in April (I had the silver G35 that we were pulling the motor on)?

Tom

Trending Topics

#8

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: Indianapolis, IN

Posts: 423

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by IIQuickSilverII

so basically youd say that the HR engine head studs are comparable to the APR L17s ...not bad!

very unique build, nice!!

very unique build, nice!!

Time permitting, this solution should prove to be a viable method for builds under 750 DD whp.

#10

New Member

iTrader: (13)

Originally Posted by jkenefic

I would say they hold more than L17s based on their ability to distribute the clamping load over a greater area of the head. With the design of the VQ head bolt location and diameter; a toque to yield bolt is going to perform better than a stud up to certain point... Now, what that point is I can not say yet.

Time permitting, this solution should prove to be a viable method for builds under 750 DD whp.

Time permitting, this solution should prove to be a viable method for builds under 750 DD whp.

the L17s were good to 906 whp so far and have been track tested too... i fyou statements are true i am sure its possible that the hr ones might hold to 1000whp then

#11

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: Indianapolis, IN

Posts: 423

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by IIQuickSilverII

the L17s were good to 906 whp so far and have been track tested too... i fyou statements are true i am sure its possible that the hr ones might hold to 1000whp then

#15

Got Track!!!!!

iTrader: (40)

Join Date: May 2005

Location: Fayetteville, NC

Posts: 3,307

Likes: 0

Received 0 Likes

on

0 Posts

I have some brand new DR's in the garage!

Those are some sick numbers! Show the trq sheet. You need a Cosworth plenum and add 25 to 30hp on that.

Good Job Joe!

Get good with that Haltech so we can throw one on the GTR

Those are some sick numbers! Show the trq sheet. You need a Cosworth plenum and add 25 to 30hp on that.

Good Job Joe!

Get good with that Haltech so we can throw one on the GTR

#16

New Member

iTrader: (18)

Nice meeting you at ZdayZ and congrats on your success. Nice tune with great power to redline!

HR headgaskets FTW! I take it the L19s were not used as the excess torque was felt to warp the mating plane? I don't think it matters - you're not going to headlift with the Evans.

HR headgaskets FTW! I take it the L19s were not used as the excess torque was felt to warp the mating plane? I don't think it matters - you're not going to headlift with the Evans.

#20

Registered User

Thread Starter

iTrader: (3)

Join Date: Jun 2005

Location: Indianapolis, IN

Posts: 423

Likes: 0

Received 0 Likes

on

0 Posts

^^^^ +1!!!

Come on people, lets keep this on topic... Jim Wolf was the person I talked to on the west coast that strongly encouraged me to try this setup. What ever VRT and RA were doing is their business and I am not going to speculate on what parts were going into their engine builds.

That is a huge part of why I went with the torque to yield HR bolts instead of the L19s in the previous 2 builds. There is a lot of good reading on this subject if anyone is interested just google it. Another thing to know about TTY bolts is that they do have some elasticity to them so when the motor heats, cools, and cyl psi change the same clamping load will be there in all conditions helping to prevent warping of surfaces. ARP studs to not do this (to the best of my knowledge) and is partly why an engine that has been run hot will have head gasket failure over time with a ARP style stud.

I would like to know if the HR bolts have enough clamping force to work on the sleeved large bore blocks. The characteristics of the HR bolts would help keep the matting surfaces flat with great displacement of the clamping load.

Come on people, lets keep this on topic... Jim Wolf was the person I talked to on the west coast that strongly encouraged me to try this setup. What ever VRT and RA were doing is their business and I am not going to speculate on what parts were going into their engine builds.

HR headgaskets FTW! I take it the L19s were not used as the excess torque was felt to warp the mating plane?

I would like to know if the HR bolts have enough clamping force to work on the sleeved large bore blocks. The characteristics of the HR bolts would help keep the matting surfaces flat with great displacement of the clamping load.