ST/SU Build

#322

Looking for advice on the harness bar position. Im planning on putting a horizontal bar right behind the seat in the plane of the main hoop with a belt angle of 10 degrees down. My question is, is there a minimum distance required from the mounting point of the shoulder bars to the seat openings? I read the SCCA, NASA and FIA rule books and cant find anything but couldve sworn I heard someone say there was a minimum requirement... If there is not minimum distance required can i run it fairly close to the seat and still take up enough slack? If not i can always design the bar to bend outwards (away from the seat)... Any advice is appreciated!!

#324

#325

Thinking of doing a taco gusset on the lower side of the front X... does anyone know if I have to cut the tips of the triangle out to leave the welds exposed or is it OK if the gusset covers some weld. Have read contradicting info and nothing concrete in rule book....

#326

Clearance from back of seat is good. Realized had the seat way to far back when initially mocking it up. The bar will put the harness at a 10 degree angle per fia rule book.

Thinking of doing a taco gusset on the lower side of the front X... does anyone know if I have to cut the tips of the triangle out to leave the welds exposed or is it OK if the gusset covers some weld. Have read contradicting info and nothing concrete in rule book....

Thinking of doing a taco gusset on the lower side of the front X... does anyone know if I have to cut the tips of the triangle out to leave the welds exposed or is it OK if the gusset covers some weld. Have read contradicting info and nothing concrete in rule book....

If you leave it as a solid taco, I would cut the tips to allow out gasing to keep your weld from blowing out as you end the bead. It does look cleaner when the weld doesn't bunch up at the corner and there is little stength to gain by a complete weld to the tip.

#327

I prefer the taco-gusset, light and strong. I really like when people dimple punch the center. You can use the punched hole to back-purge during welding if you decide to go crazy. I think the cut at the tip is for you to decide, as far as I read, the FIA doesn't specify that detail...which means it's open to interpretation.

If you leave it as a solid taco, I would cut the tips to allow out gasing to keep your weld from blowing out as you end the bead. It does look cleaner when the weld doesn't bunch up at the corner and there is little stength to gain by a complete weld to the tip.

If you leave it as a solid taco, I would cut the tips to allow out gasing to keep your weld from blowing out as you end the bead. It does look cleaner when the weld doesn't bunch up at the corner and there is little stength to gain by a complete weld to the tip.

I agree they look dope, but not worth $300 for one time use IMO.

I agree they look dope, but not worth $300 for one time use IMO. Thanks for the tip though.

#328

6 inch cawk is my fave!

iTrader: (3)

Quick question from page 1 or 2 you said you removed your A.C..... Was their a noticeable difference from not cranking that pully? I hardly ever use my A.C. Because I like the windows down. Any drawbacks from removing it other than the no cold air in the summer factor...

My car is basically a weekend toy that never gets driven on a track or anything....

My car is basically a weekend toy that never gets driven on a track or anything....

#329

Either that, or look into a tool rental for something like that. It is never wise to spend $300 for 15 mins of use.

#330

Quick question from page 1 or 2 you said you removed your A.C..... Was their a noticeable difference from not cranking that pully? I hardly ever use my A.C. Because I like the windows down. Any drawbacks from removing it other than the no cold air in the summer factor...

My car is basically a weekend toy that never gets driven on a track or anything....

My car is basically a weekend toy that never gets driven on a track or anything....

The following users liked this post:

dboyzalter (03-18-2017)

#332

#333

Hardest Setting

iTrader: (3)

Join Date: Feb 2008

Location: MexiCali dodging potholes

Posts: 13,406

Received 130 Likes

on

102 Posts

I really like where you placed the cage, for me a big guy (6'4 2XXlbs) this is the first time I've seen someone put it behind the driver divide...

so much room for the driver !

more

so much room for the driver !

more

#334

Ideally I was going to line the bottom of the taco up perfect with the drivers bar but fia rules specificy that taco gussets in main hoop need to be 3x tube diameter.... so that's what I got.

@king baby

I'm 6'0 and even having the cage where it is leaves not too much space for driver, can't imagine it being mounting on lower floor...if it were on the lower floor it'd start to get in the way of entry/exit of vehicle too... it'll b hard enough with door bsrs, don't need any other obstacles!

#335

That's the plan, are you thinking there is an issue? Please voice concerns now before I weld it in.

Ideally I was going to line the bottom of the taco up perfect with the drivers bar but fia rules specificy that taco gussets in main hoop need to be 3x tube diameter.... so that's what I got.

@king baby

I'm 6'0 and even having the cage where it is leaves not too much space for driver, can't imagine it being mounting on lower floor...if it were on the lower floor it'd start to get in the way of entry/exit of vehicle too... it'll b hard enough with door bsrs, don't need any other obstacles!

Ideally I was going to line the bottom of the taco up perfect with the drivers bar but fia rules specificy that taco gussets in main hoop need to be 3x tube diameter.... so that's what I got.

@king baby

I'm 6'0 and even having the cage where it is leaves not too much space for driver, can't imagine it being mounting on lower floor...if it were on the lower floor it'd start to get in the way of entry/exit of vehicle too... it'll b hard enough with door bsrs, don't need any other obstacles!

I'm just asking the dumb questions, I haven't looked at the rule book in a while. My project has been lonely as I become days away from my wedding!

#336

I was only asking for me an aesthetic point of view. If that's what you end up, it's obviously only right to follow the rules. The fia spec will cover you for nasa and scca of course.

I'm just asking the dumb questions, I haven't looked at the rule book in a while. My project has been lonely as I become days away from my wedding!

I'm just asking the dumb questions, I haven't looked at the rule book in a while. My project has been lonely as I become days away from my wedding!

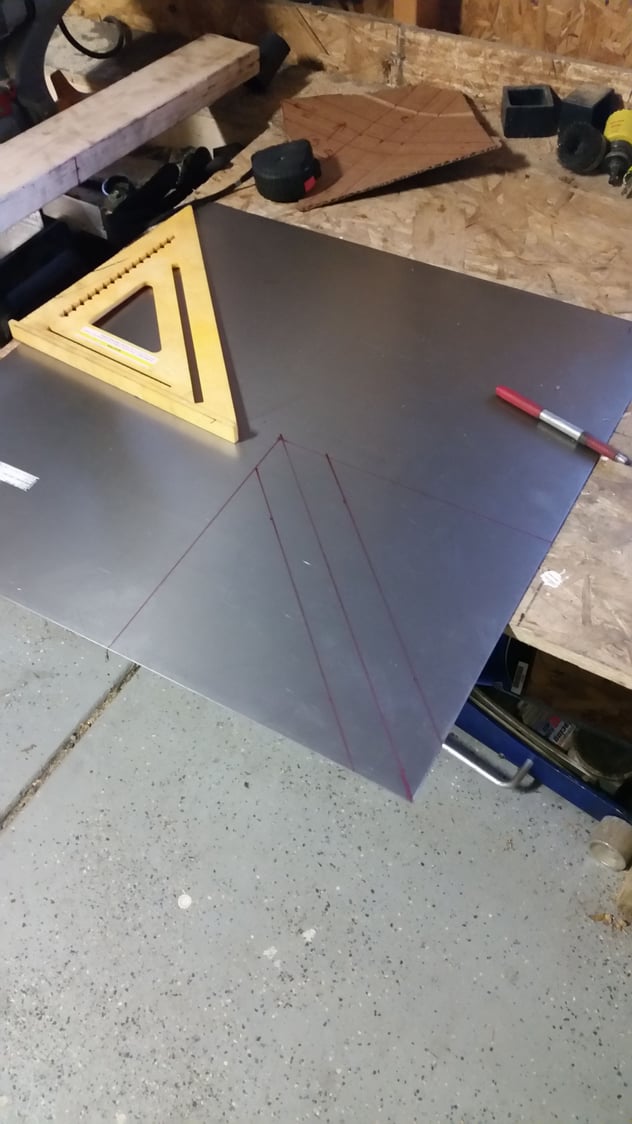

Anyways, welded in the gusset and got the a pillar footings complete.

#337

Does anyone have any reason why i shouldnt weld 16ga sheet steel over the location where i will be welding my main hoop footing? My thoughts are itd be easier to weld the 16ga to the thin car sheet metal then weld the footing to that... Or some tips on welding my 1/4" footing to 20ish ga sheet?