DIY Closed Deck...

#1

Thread Starter

Registered User

Joined: Jan 2004

Posts: 1,337

Likes: 0

From: ATL-What U Know About That???

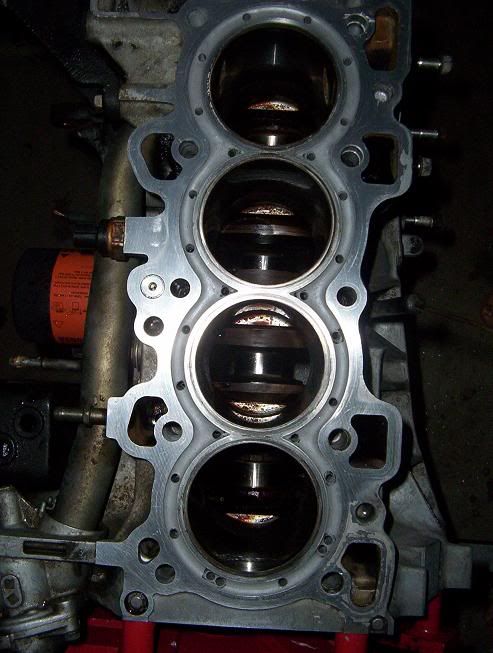

Read about this a while back on another forum (honda) and it was very interesting. I saved a pic and totally forgot about this until I was surfing through some photos on my computer. So, I quickly remembered the process somewhat and wanted to post it here for debate purposes.

Anyway, the process involves using Devcon liquid aluminum to close the deck of the motor, much like a block guard. I know many have had problems with block guards in the past, to the point where they warped the cylinders because of they way they were installed and/or manufactured. Which leads to what I think would be benefit number 1: This is an metal filled epoxy that will conform to the shape it is poured in so there would be no way to distort the cylinders.

Now I CAN vouch for Devcon products because I have used them when I was an aircraft mechanic. We mainly used the paste form of this stuff to build up turbine engine transmission cases and mating surfaces. I will tell you this stuff is absolutely freakin' strong. In cured form it has to actually be machined!! Devcon says you can file this stuff but I've tried and it barely left a mark. Another note, we've popped this stuff with a ball peen hammer once and it took a few solid whacks to chip it. AND, it only chipped in the area it was struck leaving the surrounding area still bonded to the surface. The Devcon product this DIY uses is the less viscous pourable form used to produce molds, which in turn also has to be machined to final specs. The key is absolute perfection in maintaining a clean bonding surface. It may even help to use alodine and etch the bonding surface since this block is aluminum.

As far as heat transfer is concerned, being that it's made up of aluminum it does have a pretty high co-efficient of thermal expansion. How this expansion is compared to the block and cylinders I have no idea. The guy who did this mod is supposedly pushing 400whp on a Honda block with know problems what so ever.

The Process:

Basically the block is kept level. The surfaces are prepped with 80 grit, I suggest alodine as well, and cleaned. A line is marked above the coolant port on the block and then filled with salt and all air removed. Something not mentioned that I'd also suggest is going around the block and tapping it with a dead blow hammer to settle and level the salt. Next the liquid aluminum is poured through a funnel and leveled. According to the writeup you actually have to run your finger around the bead to recess this stuff about a 16th of an inch below the top of the cylinders. Anyway, you have to let it cure for about 4 hrs, then cure it under 200 degrees for 4 more hours and let it sit for another 18-24 hours. Once fully cured you place your head gasket on the block, mark the cooling passage holes and drill those out.

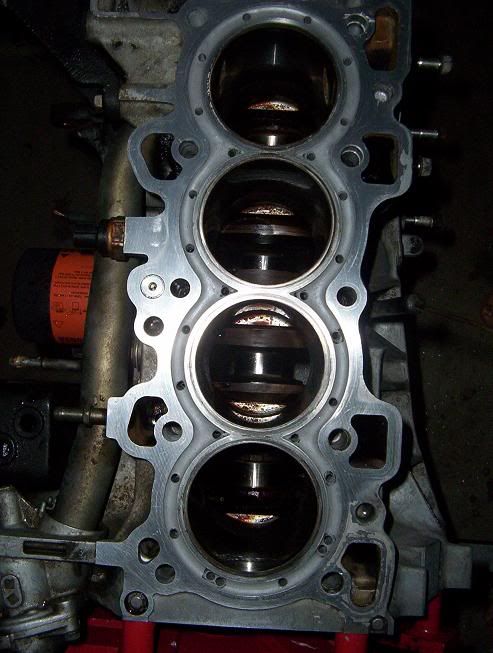

This is the final result:

So what do you guys think??

Anyway, the process involves using Devcon liquid aluminum to close the deck of the motor, much like a block guard. I know many have had problems with block guards in the past, to the point where they warped the cylinders because of they way they were installed and/or manufactured. Which leads to what I think would be benefit number 1: This is an metal filled epoxy that will conform to the shape it is poured in so there would be no way to distort the cylinders.

Now I CAN vouch for Devcon products because I have used them when I was an aircraft mechanic. We mainly used the paste form of this stuff to build up turbine engine transmission cases and mating surfaces. I will tell you this stuff is absolutely freakin' strong. In cured form it has to actually be machined!! Devcon says you can file this stuff but I've tried and it barely left a mark. Another note, we've popped this stuff with a ball peen hammer once and it took a few solid whacks to chip it. AND, it only chipped in the area it was struck leaving the surrounding area still bonded to the surface. The Devcon product this DIY uses is the less viscous pourable form used to produce molds, which in turn also has to be machined to final specs. The key is absolute perfection in maintaining a clean bonding surface. It may even help to use alodine and etch the bonding surface since this block is aluminum.

As far as heat transfer is concerned, being that it's made up of aluminum it does have a pretty high co-efficient of thermal expansion. How this expansion is compared to the block and cylinders I have no idea. The guy who did this mod is supposedly pushing 400whp on a Honda block with know problems what so ever.

The Process:

Basically the block is kept level. The surfaces are prepped with 80 grit, I suggest alodine as well, and cleaned. A line is marked above the coolant port on the block and then filled with salt and all air removed. Something not mentioned that I'd also suggest is going around the block and tapping it with a dead blow hammer to settle and level the salt. Next the liquid aluminum is poured through a funnel and leveled. According to the writeup you actually have to run your finger around the bead to recess this stuff about a 16th of an inch below the top of the cylinders. Anyway, you have to let it cure for about 4 hrs, then cure it under 200 degrees for 4 more hours and let it sit for another 18-24 hours. Once fully cured you place your head gasket on the block, mark the cooling passage holes and drill those out.

This is the final result:

So what do you guys think??

#2

I've seen and heard about this from a customer or two (both honda owners).

However, I haven't personally seen any proof of whether its a worthwhile to do or not, and the long term effects.

Great mod in theory tho.

However, I haven't personally seen any proof of whether its a worthwhile to do or not, and the long term effects.

Great mod in theory tho.

#5

so you are saying thAT the cooling channels are drilled before it fully cures? who wants to volunteer to be the tester for this? 900rwhp on a stock block anyone?

Sounds good in theory, but I've heard of stories of honda guys filling their block with other materials and having issues (but then again, it was with other materials)

-TODD

Sounds good in theory, but I've heard of stories of honda guys filling their block with other materials and having issues (but then again, it was with other materials)

-TODD

#6

Originally Posted by 350zDCalb

so you are saying thAT the cooling channels are drilled before it fully cures? who wants to volunteer to be the tester for this? 900rwhp on a stock block anyone?

Sounds good in theory, but I've heard of stories of honda guys filling their block with other materials and having issues (but then again, it was with other materials)

-TODD

Sounds good in theory, but I've heard of stories of honda guys filling their block with other materials and having issues (but then again, it was with other materials)

-TODD

Im gunna fill mine with NAWS yo!!

Trending Topics

#8

If you look into these further, the Honda guys never use them anymore. They create localized hot spots and stress points which end up destroying the motor. They stopped using those long ago.

Thread

Thread Starter

Forum

Replies

Last Post

Gruppe-S

Body Interior

13

05-16-2016 10:42 PM

Vigman

Maintenance & Repair

17

11-17-2015 04:34 AM