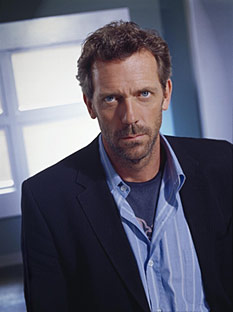

I cracked the sleeve in my subframe!

#1

Can this be fixed?

I am guessing I have to drop the whole subframe, have the aluminum bushing "pressed" into the sleeve, then have a welder repair it. (Maybe weld the bushing into the sleeve to help reinforce it.)

I am guessing I have to drop the whole subframe, have the aluminum bushing "pressed" into the sleeve, then have a welder repair it. (Maybe weld the bushing into the sleeve to help reinforce it.)

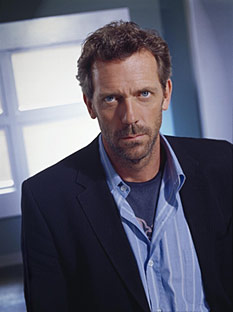

#2

She's flat-lined. I'm sorry, but there was nothing we could do for her. We've tried everything, but we couldn't bring her back. Just be thankful she went this way instead of Lupus.

Last edited by Hexxus; 05-13-2010 at 07:06 PM.

#3

#4

That's where one of the four large bushings go in the rear suspension, isn't it?

I suppose you could have it TIG-welded or done with a spool gun, but I'm not seeing it as a big deal as long as the crack doesn't extend into the original factory weld.

I suppose you could have it TIG-welded or done with a spool gun, but I'm not seeing it as a big deal as long as the crack doesn't extend into the original factory weld.

Last edited by winchman; 05-13-2010 at 10:56 PM.

#5

I was thinking it might be ok, but I track my car and I don't want to drop the pumpkin again anytime soon. but if the mobile welder can come over and fix it while it's up on jack stands, the $100/hr he charges will be well worth the piece of mind.

Welding the bushing into place (while he's here) might make the subframe even stronger than before?

Last edited by Z1NONLY; 05-14-2010 at 03:36 AM.

#6

Is that the diff side or the exhaust side of the rear subframe bushing hole?

either way, welding is your only option in repair....

Dont have the welder just weld over top of it.....

the hanging over edge would best be cut at a V and make a V groove.

also the crack that extends into the bushing area would best be "stop drilled"

drill about a 5/16 diameter hole at the crack tip, and then have the welder weld fill and sand/file down smooth the weldment to allow the solid bushing to be installed. the stop dril method may not be needed "IF" the V groove eliminates the tip........as im not there to see where the crack tip ends.........

As for welding the bushing into place, sure you can if you want, as the intended purpose is to ensure the bushing stays in place, but i would advise not to do so unless you know the material properties and know it is weldable aluminum.....not all aluminum is weldable...usually 6061 series is...

Also, regardless of how well a weld repair "looks" this will in the end be something you will always have to inspect....

most cracks along welds follow the weld, so later down the road inspection is crutial...

the other option is to grab another subframe from the junk yard.......as nearly every Z i have seen at a local junk yard is a front end collision..

I say weld it and if it ever gets worse, then i would do the junk yard find idea...

-J

either way, welding is your only option in repair....

Dont have the welder just weld over top of it.....

the hanging over edge would best be cut at a V and make a V groove.

also the crack that extends into the bushing area would best be "stop drilled"

drill about a 5/16 diameter hole at the crack tip, and then have the welder weld fill and sand/file down smooth the weldment to allow the solid bushing to be installed. the stop dril method may not be needed "IF" the V groove eliminates the tip........as im not there to see where the crack tip ends.........

As for welding the bushing into place, sure you can if you want, as the intended purpose is to ensure the bushing stays in place, but i would advise not to do so unless you know the material properties and know it is weldable aluminum.....not all aluminum is weldable...usually 6061 series is...

Also, regardless of how well a weld repair "looks" this will in the end be something you will always have to inspect....

most cracks along welds follow the weld, so later down the road inspection is crutial...

the other option is to grab another subframe from the junk yard.......as nearly every Z i have seen at a local junk yard is a front end collision..

I say weld it and if it ever gets worse, then i would do the junk yard find idea...

-J

Last edited by JasonZ-YA; 05-14-2010 at 04:11 AM.

#7

Is that the diff side or the exhaust side of the rear subframe bushing hole?

either way, welding is your only option in repair....

Dont have the welder just weld over top of it.....

the hanging over edge would best be cut at a V and make a V groove.

also the crack that extends into the bushing area would best be "stop drilled"

drill about a 5/16 diameter hole at the crack tip, and then have the welder weld fill and sand/file down smooth the weldment to allow the solid bushing to be installed. the stop dril method may not be needed "IF" the V groove eliminates the tip........as im not there to see where the crack tip ends.........

As for welding the bushing into place, sure you can if you want, as the intended purpose is to ensure the bushing stays in place, but i would advise not to do so unless you know the material properties and know it is weldable aluminum.....not all aluminum is weldable...usually 6061 series is...

Also, regardless of how well a weld repair "looks" this will in the end be something you will always have to inspect....

most cracks along welds follow the weld, so later down the road inspection is crutial...

the other option is to grab another subframe from the junk yard.......as nearly every Z i have seen at a local junk yard is a front end collision..

I say weld it and if it ever gets worse, then i would do the junk yard find idea...

-J

either way, welding is your only option in repair....

Dont have the welder just weld over top of it.....

the hanging over edge would best be cut at a V and make a V groove.

also the crack that extends into the bushing area would best be "stop drilled"

drill about a 5/16 diameter hole at the crack tip, and then have the welder weld fill and sand/file down smooth the weldment to allow the solid bushing to be installed. the stop dril method may not be needed "IF" the V groove eliminates the tip........as im not there to see where the crack tip ends.........

As for welding the bushing into place, sure you can if you want, as the intended purpose is to ensure the bushing stays in place, but i would advise not to do so unless you know the material properties and know it is weldable aluminum.....not all aluminum is weldable...usually 6061 series is...

Also, regardless of how well a weld repair "looks" this will in the end be something you will always have to inspect....

most cracks along welds follow the weld, so later down the road inspection is crutial...

the other option is to grab another subframe from the junk yard.......as nearly every Z i have seen at a local junk yard is a front end collision..

I say weld it and if it ever gets worse, then i would do the junk yard find idea...

-J

Trending Topics

#8

Thanks guys. The welder is on his way now. I will report back later.

I spoke with SPL and they said it could be welded. It's the diff side, BTW.

I spoke with SPL and they said it could be welded. It's the diff side, BTW.

Last edited by Z1NONLY; 05-14-2010 at 09:15 AM.

#9

Well it's not pretty, but I wasn't going for "form" anyway.

Took it for a test drive. Did a few hard launches, (looking for wheel hop) and found none.

Also put her back up in the air after the test drive and checked everything out. All looks good.

I never did find my caliper, so I didn't get any measurements. (Sorry) -Even forgot to weigh the pumpkin.

Took it for a test drive. Did a few hard launches, (looking for wheel hop) and found none.

Also put her back up in the air after the test drive and checked everything out. All looks good.

I never did find my caliper, so I didn't get any measurements. (Sorry) -Even forgot to weigh the pumpkin.

Last edited by Z1NONLY; 05-14-2010 at 06:26 PM.

Thread

Thread Starter

Forum

Replies

Last Post